Information injection-pump assembly

BOSCH

9 400 613 004

9400613004

ZEXEL

101608-6400

1016086400

Rating:

Service parts 101608-6400 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME440071

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101608-6400

as INJECTION-PUMP ASSEMBLY

Include in #2:

104748-0139

as _

Cross reference number

BOSCH

9 400 613 004

9400613004

ZEXEL

101608-6400

1016086400

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

109.5

108.5

110.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Injection quantity adjustment_02

Adjusting point

-

Rack position

8+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

16.5

15

18

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

11.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

375

375

375

Rack position

9.2

Boost pressure

kPa

10.7

4

17.4

Boost pressure

mmHg

80

30

130

Boost compensator adjustment_02

Pump speed

r/min

375

375

375

Rack position

10.45

Boost pressure

kPa

56

50.6

56

Boost pressure

mmHg

420

380

420

Timer adjustment

Pump speed

r/min

600

Advance angle

deg.

3

2.5

3.5

Load

0/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

720

Advance angle

deg.

0.5

Load

0/4

Timer adjustment_03

Pump speed

r/min

(850)

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/4

Remarks

Finish

Finish

Test data Ex:

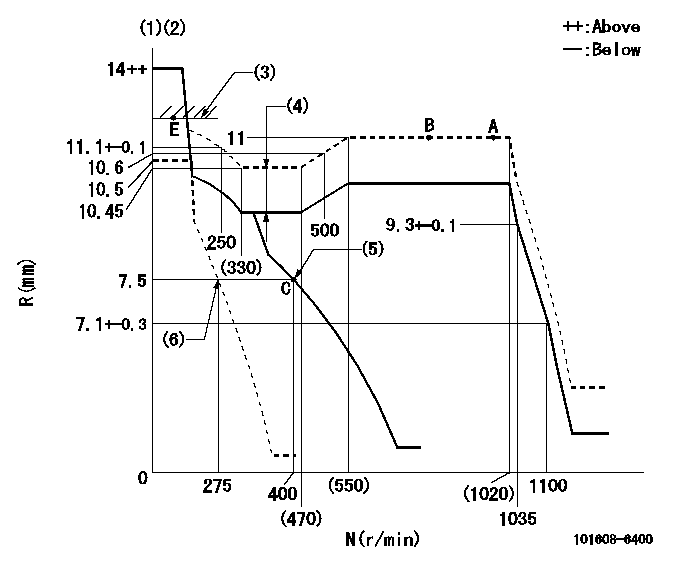

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

(5)Main spring setting

(6)Set idle sub-spring

----------

K=10 BCL=1.25+-0.1mm

----------

----------

K=10 BCL=1.25+-0.1mm

----------

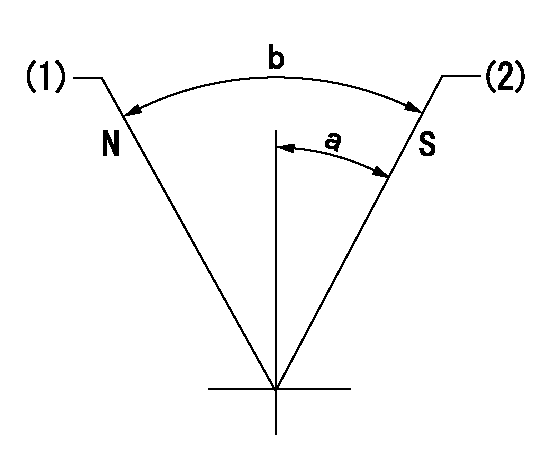

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=18deg+-5deg b=0deg+-5deg

----------

----------

a=18deg+-5deg b=0deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2 maximum)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

0000001601 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Mount the joint (B).

(2)Select the shim (D) so that the rack limit's rack position is obtained at that time.

(3)Install the rod (E) to the block (C).

The distance between the pump end face and the rod (E) at rack limit must be L.

2. Rack sensor adjustment (-0020)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set at speed N.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.01 (V), then tighten the nut (F). (If equipped with a boost compensator, perform with boost pressure applied.)

(5)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(6)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=38-0.2mm N=1000r/min Ra=11mm

----------

----------

L=38-0.2mm N=1000r/min Ra=11mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=8deg

----------

a=(3deg)

----------

aa=8deg

----------

a=(3deg)

Information:

The front plate is bolted inside the timing gear case. Do not attempt to remove this plate along with the timing gear case by tapping.

Front plate attaching bolts8. Timing gear backlash measurement Measure the backlash of each gear and keep a record of it for correct installation. Replace the gears if the backlash exceeds the limit.

Unit: mm (in.)

Measuring timing gear backlash9. Idler gear removal To remove the idler gear, rotate the gear in a direction of the helix of the teeth to pull it out of mesh.

Removing idler gear10. Camshaft removal (1) Remove the bolts that hold the thrust plate. (2) Pull the camshaft out of the cylinder block.

Do not cause damage to the lobes or bearing journals when removing the camshaft.

Removing camshaft11. Fuel injection pump camshaft removal(1) Remove the stopper bolt.

Removing camshaft stopper bolt(2) Tap the rear end of the camshaft with a copper bar to push it out of the front side of the cylinder block.

Removing fuel injection pump camshaft12. Gear removal (when required) To remove the gears from the camshaft and fuel injection pump camshaft, use an arbor press.13. Oil pump removal Remove the bolts that hold the oil pump to the cylinder block and remove the pump.

Removing oil pump14. Front plate removal Remove four bolts that hold the front plate in position. Tap the plate lightly with a plastic hammer to separate the gasket.

Removing front plateCYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

1 Oil pan2 Oil screen3 Connecting rod cap4 Connecting rod bearing (lower half) (Remove 5 thru 10 as an assembly.)5 Connecting rod6 Piston pin7 No. 1 ring8 No. 2 ring9 Oil ring10 Piston11 Connecting rod bearing (upper half)12 Main bearing cap13 Main bearing (lower half)14 Crankshaft15 Main bearing (upper half)16 Cylinder block When the cylinder block is to be discarded, remove the components (pressure relief valve, etc.) from the block for reuse. 1. Oil pan removal (1) Turn the engine upside down.(2) Tap the bottom corners of the oil pan with a plastic hammer to remove the oil pan.

Do not attempt to pry off the oil pan by inserting a screwdriver or a chisel between the oil pan and cylinder block. Damage to the oil pan can be the result.

Removing oil pan2. Oil screen removal Loosen the nut that holds the oil screen in position and remove the screen.

Removing oil screen3. Thrust clearance measurement for connecting rod big endInstall the connecting rod to its crankpin and tighten the cap nuts to the specified torque. Measure the thrust clearance with a feeler gauge. If the clearance exceeds the limit, replace the connecting rod.

Measuring thrust clearance for connecting rod big end

Unit: mm (in.)4. Connecting rod cap removal (1) Lay the cylinder block on its side.(2) Put identification on each connecting rod and cap combination as to its location in the engine.(3) Remove the caps.

Removing connecting rod caps5. Piston removal (1) Turn the crankshaft until the piston is at top center. (2) Push the piston and connecting rod away from the crankshaft with the handle of

Front plate attaching bolts8. Timing gear backlash measurement Measure the backlash of each gear and keep a record of it for correct installation. Replace the gears if the backlash exceeds the limit.

Unit: mm (in.)

Measuring timing gear backlash9. Idler gear removal To remove the idler gear, rotate the gear in a direction of the helix of the teeth to pull it out of mesh.

Removing idler gear10. Camshaft removal (1) Remove the bolts that hold the thrust plate. (2) Pull the camshaft out of the cylinder block.

Do not cause damage to the lobes or bearing journals when removing the camshaft.

Removing camshaft11. Fuel injection pump camshaft removal(1) Remove the stopper bolt.

Removing camshaft stopper bolt(2) Tap the rear end of the camshaft with a copper bar to push it out of the front side of the cylinder block.

Removing fuel injection pump camshaft12. Gear removal (when required) To remove the gears from the camshaft and fuel injection pump camshaft, use an arbor press.13. Oil pump removal Remove the bolts that hold the oil pump to the cylinder block and remove the pump.

Removing oil pump14. Front plate removal Remove four bolts that hold the front plate in position. Tap the plate lightly with a plastic hammer to separate the gasket.

Removing front plateCYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

1 Oil pan2 Oil screen3 Connecting rod cap4 Connecting rod bearing (lower half) (Remove 5 thru 10 as an assembly.)5 Connecting rod6 Piston pin7 No. 1 ring8 No. 2 ring9 Oil ring10 Piston11 Connecting rod bearing (upper half)12 Main bearing cap13 Main bearing (lower half)14 Crankshaft15 Main bearing (upper half)16 Cylinder block When the cylinder block is to be discarded, remove the components (pressure relief valve, etc.) from the block for reuse. 1. Oil pan removal (1) Turn the engine upside down.(2) Tap the bottom corners of the oil pan with a plastic hammer to remove the oil pan.

Do not attempt to pry off the oil pan by inserting a screwdriver or a chisel between the oil pan and cylinder block. Damage to the oil pan can be the result.

Removing oil pan2. Oil screen removal Loosen the nut that holds the oil screen in position and remove the screen.

Removing oil screen3. Thrust clearance measurement for connecting rod big endInstall the connecting rod to its crankpin and tighten the cap nuts to the specified torque. Measure the thrust clearance with a feeler gauge. If the clearance exceeds the limit, replace the connecting rod.

Measuring thrust clearance for connecting rod big end

Unit: mm (in.)4. Connecting rod cap removal (1) Lay the cylinder block on its side.(2) Put identification on each connecting rod and cap combination as to its location in the engine.(3) Remove the caps.

Removing connecting rod caps5. Piston removal (1) Turn the crankshaft until the piston is at top center. (2) Push the piston and connecting rod away from the crankshaft with the handle of