Rating:

Information injection-pump assembly

ZEXEL

104745-0131

1047450131

MAZDA

W90713800A

w90713800a

Cross reference number

ZEXEL

104745-0131

1047450131

MAZDA

W90713800A

w90713800a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

57.3

56.8

57.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

52

48.5

55.5

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

57.3

56.3

58.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

55.3

51.8

58.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

22.9

19.9

25.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

8

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

22.9

12.9

32.9

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

10.8

9.8

11.8

Difference in delivery

mm3/st.

1.7

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

10.8

9.3

12.3

Difference in delivery

mm3/st.

2.2

Basic

*

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

17

15

19

Difference in delivery

mm3/st.

3

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

55

90

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

50

90

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

440

310

570

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

618

589

647

Pressure

kgf/cm2

6.3

6

6.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

618

579

657

Pressure

kgf/cm2

6.3

5.9

6.7

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

7.4

7.2

7.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

0.9

0.1

1.7

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

7.4

7

7.8

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

8.9

8.1

9.7

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2100

2100

2100

Timer stroke

mm

9.8

8.8

10.6

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

44.7

44.2

45.2

Timer stroke TA

mm

6.7

6.7

6.7

Timer stroke variation dT

mm

0.7

0.5

0.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

44.7

43.7

45.7

Timer stroke TA

mm

6.7

6.7

6.7

Timer stroke variation dT

mm

0.7

0.3

1.1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

38.7

37.2

40.2

Timer stroke TA

mm

6.1

6.1

6.1

Timer stroke variation dT

mm

1.3

0.7

1.9

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.01

5.91

6.11

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.03

0.01

0.05

Control lever angle alpha

deg.

12.5

8.5

16.5

Control lever angle beta

deg.

40

37

43

Test data Ex:

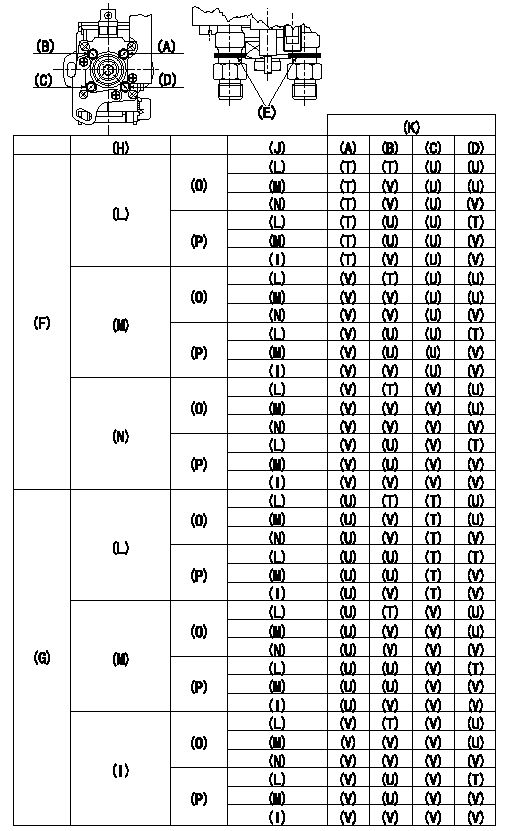

0000001801 CONTROL STANDARD AT IDLING

Standards for idle difference in delivery control

After idle adjustment, measure the idle injection quantities of (A) to (D).

Install the colored rings to the delivery valve holders (A) to (D) in accordance with the table.

(A): A cylinder (B) :B cylinder (C) : C cylinder (D): D cylinder

(E): Collar ring

(F): (A) >= (C)

(G): (C) > (A)

(H): (A) - (C) or (C) - (A)

(I): 0.2, 0.1(mm3/st)

(J): (B) - (D) or (D) - (B)

(K): Ring color

(L): At least 0.6 mm3/st

(M): 0.3, 0.4, 0.5 (mm3/st)

(N): 0.2, 0.1, 0.0 (mm3/st)

(O): (B) >= (D)

(P): (D) > (B)

(T): Yellow

(U): White

(V): Red

----------

----------

----------

----------

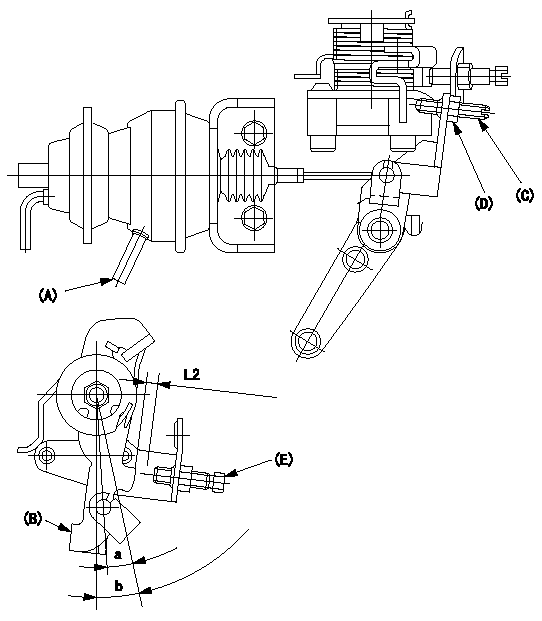

0000001901 WIRE

Confirmation of the wire length:

Accelerator wire: Idle-full stroke: L1

Adjustment of the double stage actuator:

(1)Apply negative pressure P1 {P2} to the actuator through the negative pressure inlet port (A).

(2)In condition (1), adjust using screw (C) so that control lever (B)'s position is a [ie, the distance from idle switch (E) is L2], then fix using nut (D).

T:Tightening torque

b:Alpha

----------

L1=34.1+3.5-5.5mm L2=5.1+-0.5mm a=9deg P1=-66.6kPa P2=-500mmHg T=6~9N-m(0.6~0.9kgf-m)

----------

a=9deg b=12.5+-4deg L2=5.1+-0.5mm

----------

L1=34.1+3.5-5.5mm L2=5.1+-0.5mm a=9deg P1=-66.6kPa P2=-500mmHg T=6~9N-m(0.6~0.9kgf-m)

----------

a=9deg b=12.5+-4deg L2=5.1+-0.5mm

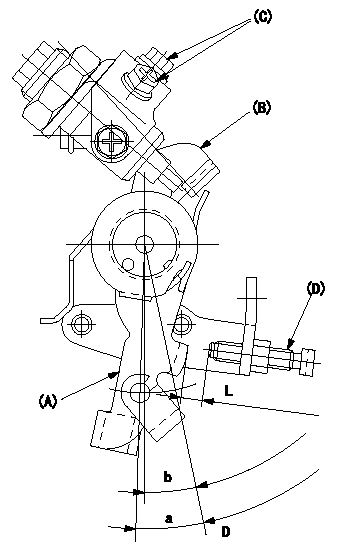

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Maintain the control lever (A) position at a (distance L from idle screw [D])

2. In this condition of item 1., adjust the position of dashpot (B) so that the end of dashpot (B) contacts the control lever (A). Then, fix using bolt (C).

Tightening torque is T.

D:Dash pot contact position

----------

L=8.1-0.3mm T=6~9N-m(0.6~0.9Kgf-m) a=14.1deg-0.5deg

----------

L=8.1-0.3mm a=14.1deg-0.5deg b=12.5deg+-4deg

----------

L=8.1-0.3mm T=6~9N-m(0.6~0.9Kgf-m) a=14.1deg-0.5deg

----------

L=8.1-0.3mm a=14.1deg-0.5deg b=12.5deg+-4deg