Rating:

Information injection-pump assembly

BOSCH

F 019 Z20 032

f019z20032

ZEXEL

101609-3860

1016093860

KOMATSU

4063203

4063203

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Agility Auto Parts 4063203 Fuel Tank Filler Neck (Use Garage Tool to Check Correct Compatibility)

AGILITY AUTO PARTS Inc. Quick-On Attachment Method || Material - Plastic || Color - Black || No - Bracket, Clamps, Hoses, Hardware Included

AGILITY AUTO PARTS Inc. Quick-On Attachment Method || Material - Plastic || Color - Black || No - Bracket, Clamps, Hoses, Hardware Included

#10 x 1/2" Hex Washer Head Self Drilling Tek Screws, Stainless Steel 410, Full Thread, Plain Finish, Self-Drilling, Quantity 500 by Fastenere

Fastenere Hex washer head self drilling screws have a drill point at the tip of the thread drills its own pilot hole in to metal allowing for quick installation and fastening while saving time and effort with just a single step || Made from an ultra strong stainless steel grade 410 giving them the ability to drill through sheet metal and stainless steel while still being wear resistant and offering a mild chemical corrosion protection; these screws are not intended for use with aluminum as the higher iron content in the fastener will cause embrittlement; 410 Stainless steel is always MAGNETIC due to the higher iron content giving the drilling capabilities || These screws have a hex head that can be driven with a nut driver or socket and can be adjusted with a wrench; the built in flanged washer adds a secure grip to the material being fastened into while also preventing the head from crushing thin metal || The self drilling point also referred to as a tek can self drill metal up to a thickness of 0.090 inches and is best used with a lot of pressure and a slow drill speed; if drilling too fast you could run the risk of over heating the metal drilling tip which could cause it to wear out or warp || Fastenere brand self drilling tapping screws will tap their own thread into the material being screwed into creating a long lasting vibration resistant connection that is the choice for use with corrugated roof siding and sheet metal applications

Fastenere Hex washer head self drilling screws have a drill point at the tip of the thread drills its own pilot hole in to metal allowing for quick installation and fastening while saving time and effort with just a single step || Made from an ultra strong stainless steel grade 410 giving them the ability to drill through sheet metal and stainless steel while still being wear resistant and offering a mild chemical corrosion protection; these screws are not intended for use with aluminum as the higher iron content in the fastener will cause embrittlement; 410 Stainless steel is always MAGNETIC due to the higher iron content giving the drilling capabilities || These screws have a hex head that can be driven with a nut driver or socket and can be adjusted with a wrench; the built in flanged washer adds a secure grip to the material being fastened into while also preventing the head from crushing thin metal || The self drilling point also referred to as a tek can self drill metal up to a thickness of 0.090 inches and is best used with a lot of pressure and a slow drill speed; if drilling too fast you could run the risk of over heating the metal drilling tip which could cause it to wear out or warp || Fastenere brand self drilling tapping screws will tap their own thread into the material being screwed into creating a long lasting vibration resistant connection that is the choice for use with corrugated roof siding and sheet metal applications

Service parts 101609-3860 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.0(224)

15.

NOZZLE SET

Include in #1:

101609-3860

as INJECTION-PUMP ASSEMBLY

Include in #2:

104268-1320

as _

Cross reference number

BOSCH

F 019 Z20 032

f019z20032

ZEXEL

101609-3860

1016093860

KOMATSU

4063203

4063203

Zexel num

Bosch num

Firm num

Name

101609-3860

F 019 Z20 032

4063203 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA6D102E K 14BE INJECTION PUMP ASSY PE6A PE

SAA6D102E K 14BE INJECTION PUMP ASSY PE6A PE

101609-3860

F 019 Z20 032

6738711260 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA6D102E K 14BE INJECTION PUMP ASSY PE6A PE

SAA6D102E K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.6

2.55

2.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

127.5

126.5

128.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

140

140

Boost pressure

mmHg

1050

1050

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

F

Rack position

11.3++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

100

110

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

8.9

Boost pressure

kPa

20

13.3

26.7

Boost pressure

mmHg

150

100

200

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

10.2

Boost pressure

kPa

80

76

84

Boost pressure

mmHg

600

570

630

Boost compensator adjustment_03

Pump speed

r/min

750

750

750

Rack position

11.1

Boost pressure

kPa

127

127

127

Boost pressure

mmHg

950

950

950

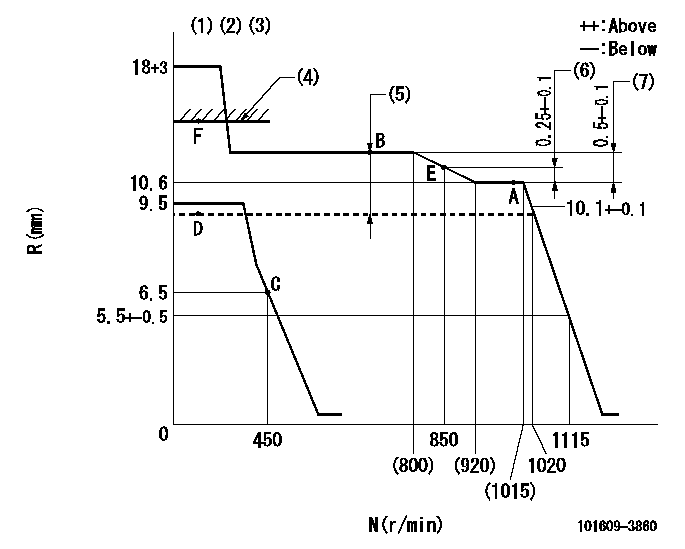

Test data Ex:

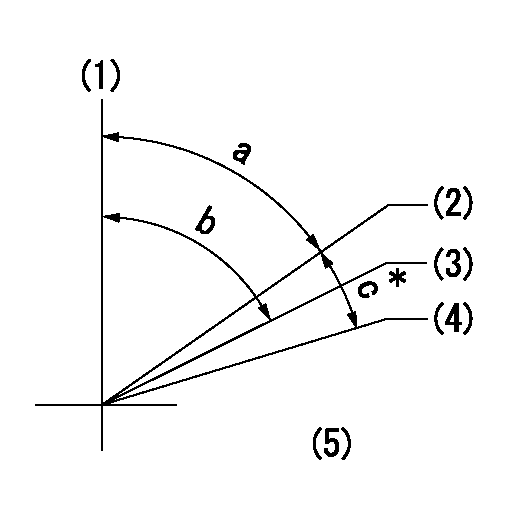

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Because the specifications are for the hydraulic actuator to be normally ON, it is not necessary to supply hydraulic pressure. (The eye bolt, however, must be installed.)

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

(6)Rack difference from N = N1

(7)Rack difference between N = N2 and N = N3

----------

K=10 BCL=2.2+-0.1mm N1=1000r/min N2=1000r/min N3=750r/min

----------

----------

K=10 BCL=2.2+-0.1mm N1=1000r/min N2=1000r/min N3=750r/min

----------

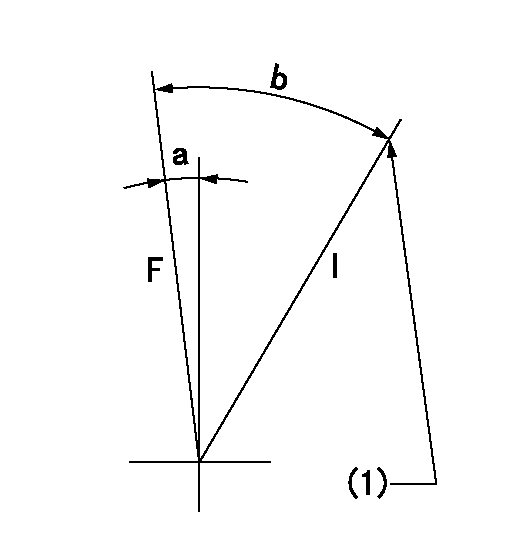

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=11deg+-5deg b=30deg+-5deg

----------

----------

a=11deg+-5deg b=30deg+-5deg

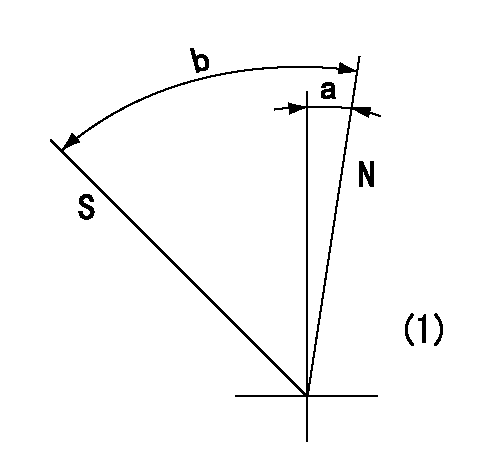

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

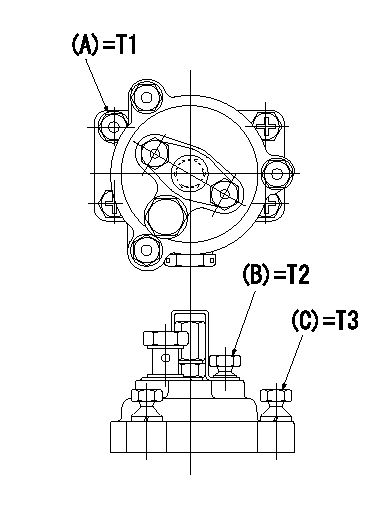

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(1)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

(3)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T3)

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

0000001601 I/P WITH LOAD PLUNGER ADJ

Adjusting procedure for load plunger equipped pump with RSV (cam lock) governor (see service information S.I. 434 for details).

At cam lift h+-0.01, set the camshaft c deg from the * mark in accordance with the timing adjustment procedure.

2. Align the flyweight's timing tooth position and the lock pin groove and then fully tighten the flyweight to the camshaft. Then, remove the lock pin.

3. Adjust the maximum variation between cylinders and injection quantity.

4. Adjust using the pre-stroke adjusting shim so that the pre-stroke value is the value for 4/4 load (standard point A).

5. After adjusting the pre-stroke, reconfirm that the injection quantity and the maximum variation between cylinders are as specified.

6. At delivery, again fix the flyweight using the lock pin.

----------

h=2.6mm c=5deg15min+-30min

----------

----------

h=2.6mm c=5deg15min+-30min

----------

Timing setting

(1)Pump vertical direction

(2)Key groove position for No. 1 cylinder's cam lift h = cc (at BTDC aa).

(3)Key groove position for No. 1 cylinder's beginning of injection (at point A after injection quantity adjustment).

(4)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(5)B.T.D.C.: aa

----------

aa=10.5deg bb=0deg cc=2.6+-0.01mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg15min+-30min

----------

aa=10.5deg bb=0deg cc=2.6+-0.01mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg15min+-30min

Have questions with 101609-3860?

Group cross 101609-3860 ZEXEL

Komatsu

Komatsu

Komatsu

101609-3860

F 019 Z20 032

4063203

INJECTION-PUMP ASSEMBLY

SAA6D102E

SAA6D102E

101609-3860

F 019 Z20 032

6738711260

INJECTION-PUMP ASSEMBLY

SAA6D102E

SAA6D102E