Rating:

Information injection-pump assembly

BOSCH

9 400 619 727

9400619727

ZEXEL

101609-3770

1016093770

Service parts 101609-3770 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.0{224}

15.

NOZZLE SET

Include in #1:

101609-3770

as INJECTION-PUMP ASSEMBLY

Include in #2:

104268-1154

as _

Cross reference number

BOSCH

9 400 619 727

9400619727

ZEXEL

101609-3770

1016093770

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.6

2.55

2.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

135

134

136

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.4+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

F

Rack position

11.7++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

100

95

105

Fixing the lever

*

Boost pressure

kPa

62.7

62.7

Boost pressure

mmHg

470

470

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

9.95

Boost pressure

kPa

26.7

24

29.4

Boost pressure

mmHg

200

180

220

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

10.5

Boost pressure

kPa

33.3

30.6

36

Boost pressure

mmHg

250

230

270

Boost compensator adjustment_03

Pump speed

r/min

650

650

650

Rack position

(11.5)

Boost pressure

kPa

49.3

49.3

49.3

Boost pressure

mmHg

370

370

370

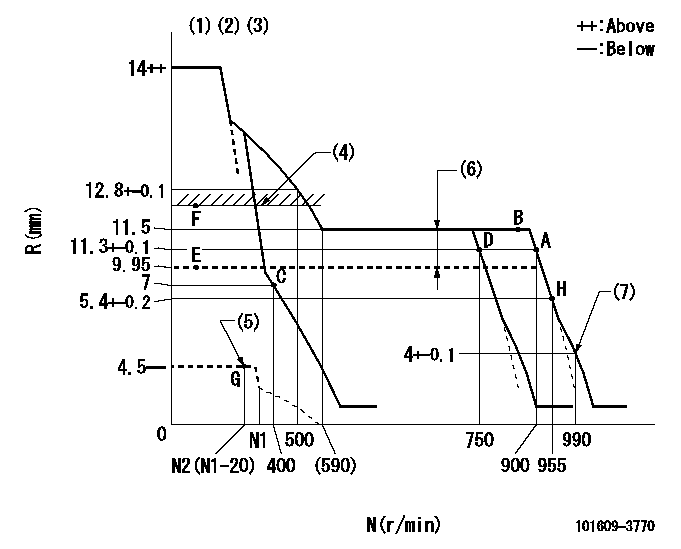

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)It is not necessary to supply hydraulic pressure because the specification is for the hydraulic ACT normally ON.

(4)RACK LIMIT

(5)Stop lever at stopping (with the speed lever at full)

(6)Boost compensator stroke: BCL

(7)Set idle sub-spring

----------

K=14 BCL=(1.55)mm

----------

----------

K=14 BCL=(1.55)mm

----------

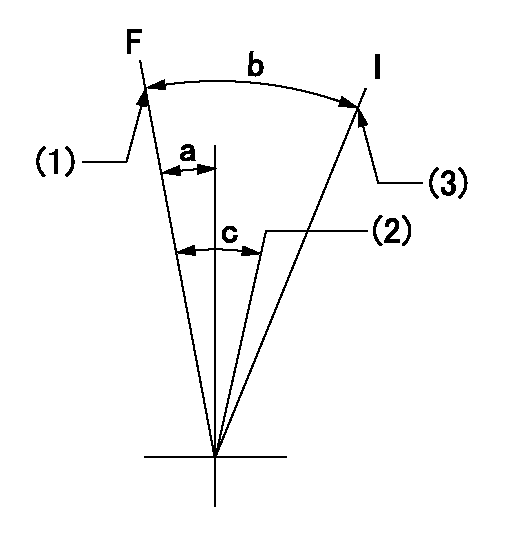

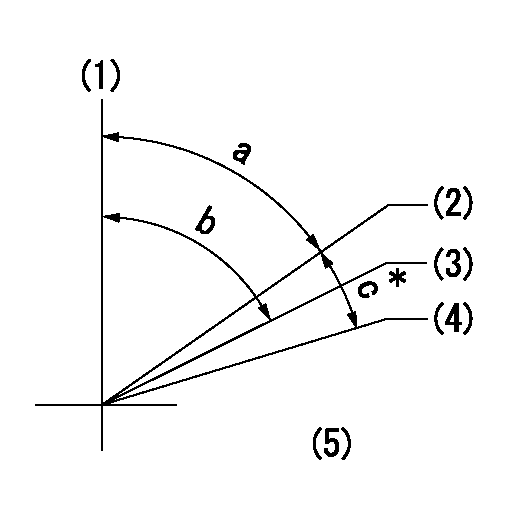

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=900r/min bb=750r/min

----------

a=1deg+-5deg b=22deg+-5deg c=6deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=1deg+-5deg b=22deg+-5deg c=6deg+-5deg

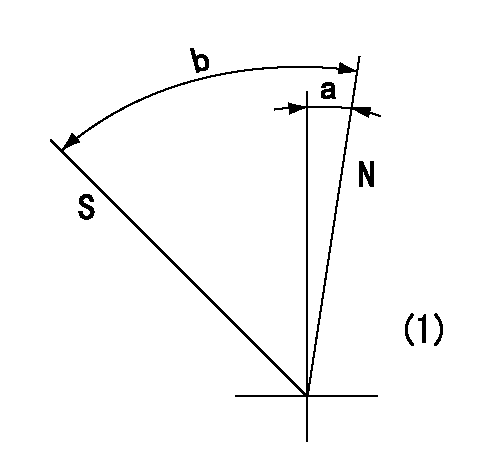

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

0000001501 I/P WITH LOAD PLUNGER ADJ

Adjusting procedure for load plunger equipped pump with RSV (cam lock) governor (see service information S.I. 434 for details).

At cam lift h+-0.01, set the camshaft c deg from the * mark in accordance with the timing adjustment procedure.

2. Align the flyweight's timing tooth position and the lock pin groove and then fully tighten the flyweight to the camshaft. Then, remove the lock pin.

3. Adjust the maximum variation between cylinders and injection quantity.

4. Adjust using the pre-stroke adjusting shim so that the pre-stroke value is the value for 4/4 load (standard point A).

5. After adjusting the pre-stroke, reconfirm that the injection quantity and the maximum variation between cylinders are as specified.

6. At delivery, again fix the flyweight using the lock pin.

----------

h=2.6+-0.01mm c=5deg+-30min

----------

----------

h=2.6+-0.01mm c=5deg+-30min

----------

Timing setting

(1)Pump vertical direction

(2)Key groove position for No. 1 cylinder's cam lift h = cc (at BTDC aa).

(3)Key groove position for No. 1 cylinder's beginning of injection (at point A after injection quantity adjustment).

(4)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(5)B.T.D.C.: aa

----------

aa=10deg bb=0deg cc=2.6+-0.01mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg+-30min

----------

aa=10deg bb=0deg cc=2.6+-0.01mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg+-30min