Rating:

Information injection-pump assembly

ZEXEL

106873-3720

1068733720

HINO

220401440A

220401440a

Cross reference number

ZEXEL

106873-3720

1068733720

HINO

220401440A

220401440a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4

3.94

4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Rack position

(13.3)

Vist

V

1.85

1.85

1.85

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

134.5

132.5

136.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(8.4)

Vist

V

2.6

2.5

2.7

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

16.9

15.9

17.9

Max. variation between cylinders

%

0

-10

10

Governor adjustment

Pump speed

r/min

710--

Advance angle

deg.

0

0

0

Load

2/5

Remarks

Q = 80.3 (mm3/st) / N = 700(r/min), beginning of effect

Q = 80.3 (mm3/st) / N = 700(r/min), beginning of effect

Governor adjustment_02

Pump speed

r/min

660

Advance angle

deg.

0.3

Load

2/5

Remarks

Q=80.3(mm3/st)/N=700(r/min)

Q=80.3(mm3/st)/N=700(r/min)

Governor adjustment_03

Pump speed

r/min

(760)

Advance angle

deg.

2

1.7

2.3

Load

5/5

Remarks

Q = 159.5 (mm3/st) / N = 1100 (r/min), measure speed

Q = 159.5 (mm3/st) / N = 1100 (r/min), measure speed

Governor adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

2

1.7

2.3

Load

4/5

Remarks

Q=147(mm3/st)/N=900 (r/min)

Q=147(mm3/st)/N=900 (r/min)

Governor adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

5.75

5.45

6.05

Load

5/5

Remarks

Q = 159.5 (mm3/st) / N = 1100 (r/min), end of effect

Q = 159.5 (mm3/st) / N = 1100 (r/min), end of effect

Test data Ex:

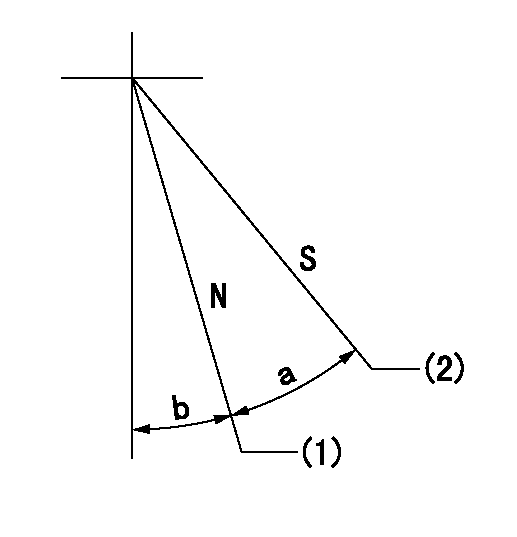

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=37deg+-5deg b=2.5deg+-5deg

----------

aa=20mm bb=1mm

----------

a=37deg+-5deg b=2.5deg+-5deg

0000000901

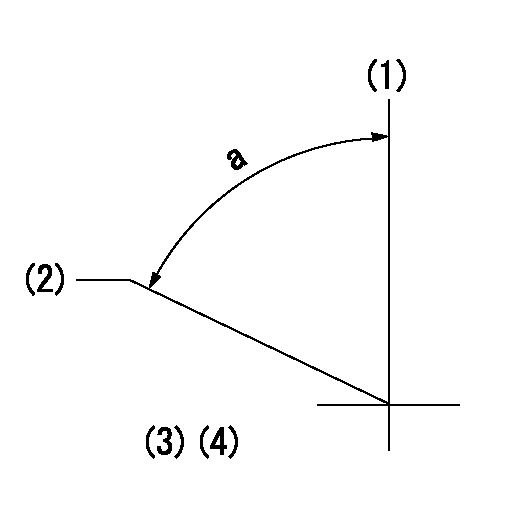

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Stop lever angle

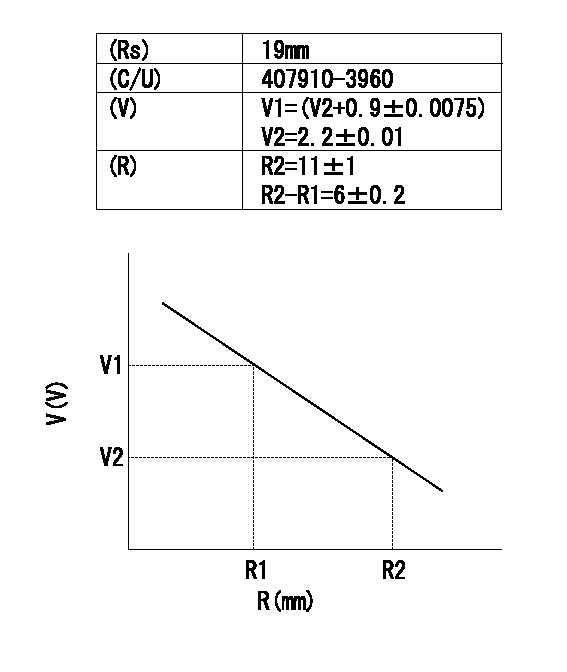

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------