Rating:

Information injection-pump assembly

BOSCH

9 400 612 705

9400612705

ZEXEL

106676-2390

1066762390

MITSUBISHI

ME158627

me158627

Service parts 106676-2390 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME158263

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

14.

NOZZLE

Include in #1:

106676-2390

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 705

9400612705

ZEXEL

106676-2390

1066762390

MITSUBISHI

ME158627

me158627

Zexel num

Bosch num

Firm num

Name

106676-2390

9 400 612 705

ME158627 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D24T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

140

137

143

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.9+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

15

12.4

17.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

105

145

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-1.25

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(10.4)

Boost pressure

kPa

17.3

10.6

24

Boost pressure

mmHg

130

80

180

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2.5

2

3

Timer adjustment_02

Pump speed

r/min

300

Advance angle

deg.

2.5

2

3

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

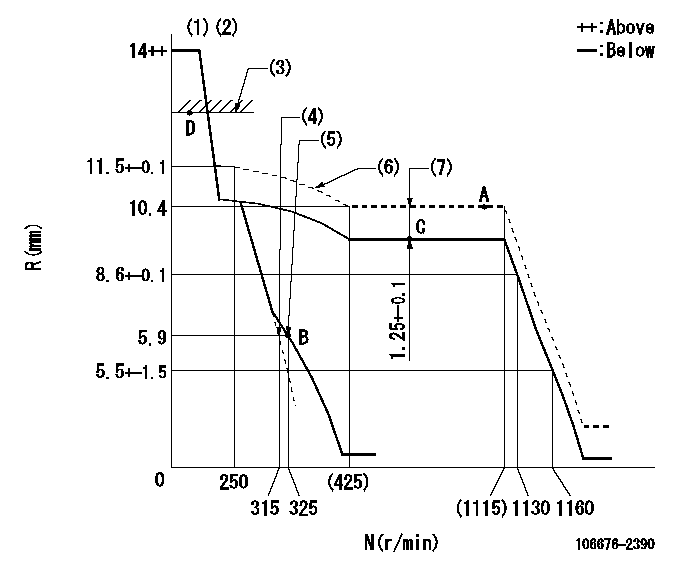

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Set idle sub-spring

(6)The torque control spring must does not have a set force.

(7)Boost compensator stroke

----------

K=6

----------

----------

K=6

----------

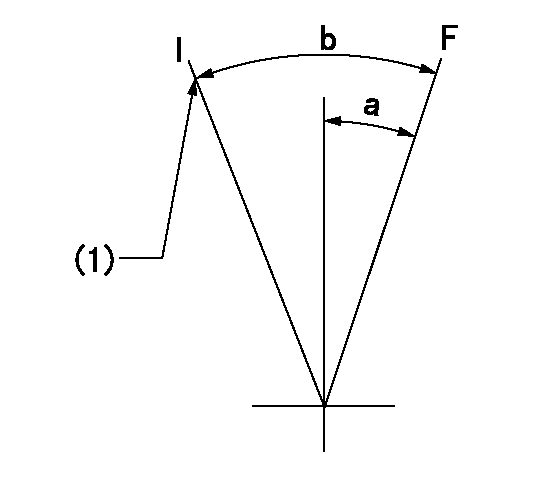

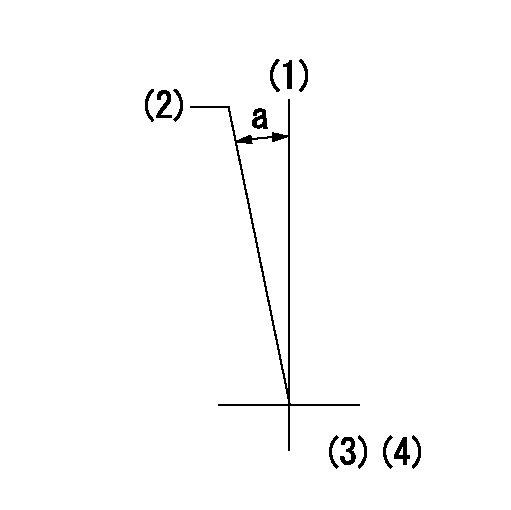

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(2deg)+-5deg b=(25deg)+-5deg

----------

----------

a=(2deg)+-5deg b=(25deg)+-5deg

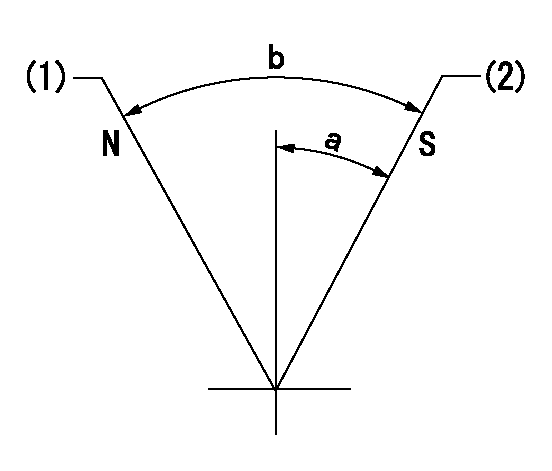

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed = aa and rack position = bb, set the stopper bolt (to be sealed at delivery).

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=70deg+-5deg

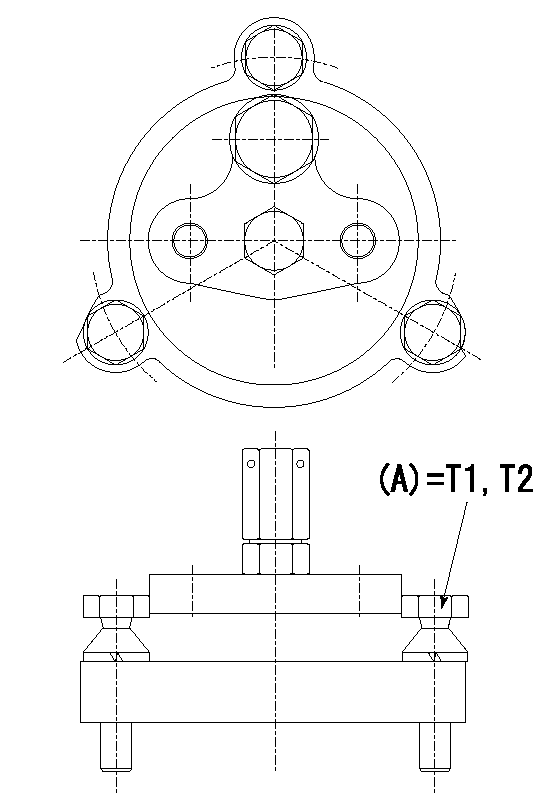

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(6deg)

----------

aa=12deg

----------

a=(6deg)

Have questions with 106676-2390?

Group cross 106676-2390 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106676-2390

9 400 612 705

ME158627

INJECTION-PUMP ASSEMBLY

6D24T

6D24T