Rating:

Information injection-pump assembly

BOSCH

9 400 617 042

9400617042

ZEXEL

106671-9200

1066719200

NIIGATA-URAWA

43547180A

43547180a

Service parts 106671-9200 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

31.4{320}

15.

NOZZLE SET

Include in #1:

106671-9200

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 042

9400617042

ZEXEL

106671-9200

1066719200

NIIGATA-URAWA

43547180A

43547180a

Zexel num

Bosch num

Firm num

Name

9 400 617 042

43547180A NIIGATA-URAWA

INJECTION-PUMP ASSEMBLY

DMF13S K 14CA INJECTION PUMP ASSY PE6P,6PD PE

DMF13S K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.05

3

3.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

185.5

180.5

190.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.4+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

54.5

51.5

57.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

12.6+0.2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

170

170

190

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

350

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

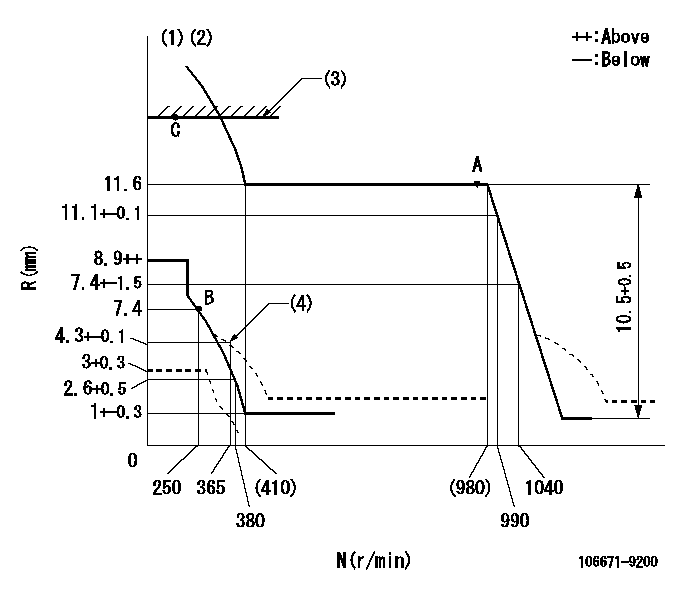

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the load lever's stop position so that R = aa (N = 0).

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Rack limit using the stop lever: R1

(4)Damper spring setting

----------

aa=3+0.3mm R1=12.6+0.2mm

----------

----------

aa=3+0.3mm R1=12.6+0.2mm

----------

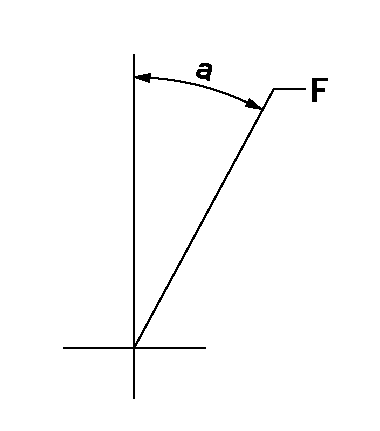

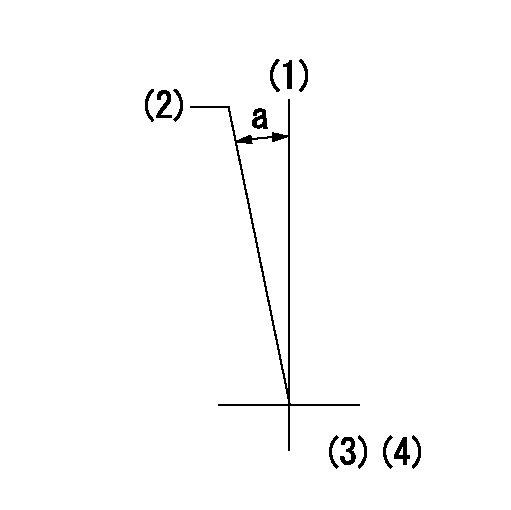

Speed control lever angle

F:Full speed

----------

----------

a=(15.5deg)+-5deg

----------

----------

a=(15.5deg)+-5deg

0000000901

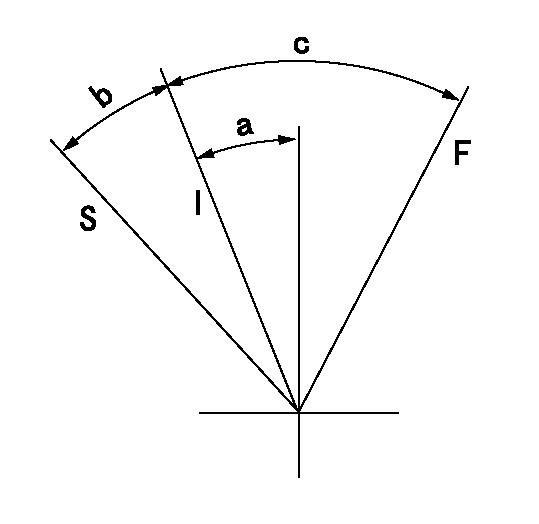

F:Full load

I:Idle

S:Stop

----------

----------

a=13deg+-5deg b=(20deg) c=39deg+-3deg

----------

----------

a=13deg+-5deg b=(20deg) c=39deg+-3deg

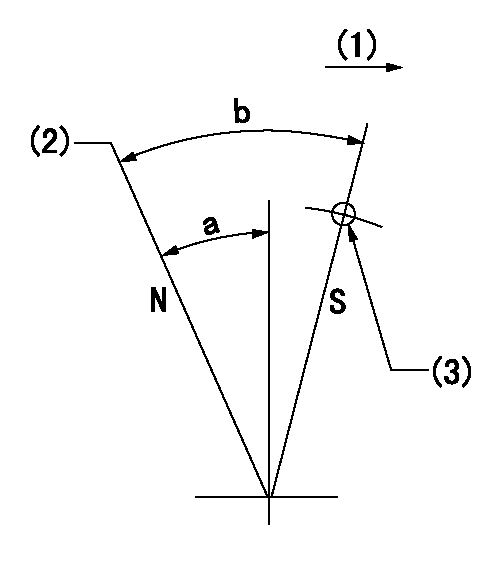

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

(2)Rack position = aa

(3)Use the hole at R = bb

----------

aa=12.6+0.2mm bb=50mm

----------

a=30.5deg+-5deg b=32.5deg+-5deg

----------

aa=12.6+0.2mm bb=50mm

----------

a=30.5deg+-5deg b=32.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(10deg)

----------

----------

a=(10deg)