Rating:

Information injection-pump assembly

BOSCH

F 01G 09W 0F9

f01g09w0f9

ZEXEL

104742-3001

1047423001

MITSUBISHI-HEAV

32A6527310

32a6527310

Cross reference number

BOSCH

F 01G 09W 0F9

f01g09w0f9

ZEXEL

104742-3001

1047423001

MITSUBISHI-HEAV

32A6527310

32a6527310

Zexel num

Bosch num

Firm num

Name

104742-3001

F 01G 09W 0F9

32A6527310 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S4S-DT

S4S-DT

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Timer measuring device installation position

Low pressure side LOW PRESSURE SIDE

Low pressure side LOW PRESSURE SIDE

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

119.7

119.2

120.2

Difference in delivery

mm3/st.

11

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

75.7

69.2

82.2

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

119.7

117.2

122.2

Difference in delivery

mm3/st.

11.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

126.5

121

132

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

123.5

118

129

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1425

1425

1425

Average injection quantity

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1425

1425

1425

Average injection quantity

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

117.9

117.9

Oil temperature

degC

50

48

52

Remarks

(check)

(check)

Governor adjustment

Pump speed

r/min

595

595

595

Average injection quantity

mm3/st.

8.1

6.1

10.1

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment_02

Pump speed

r/min

595

595

595

Average injection quantity

mm3/st.

8.1

5.6

10.6

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

95

145

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

95

145

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

595

595

595

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

595

595

595

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet ON at idling position and stop lever operate

Magnet ON at idling position and stop lever operate

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity with S/T ON

cm3/min

540

410

670

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

696

647

745

Pressure with S/T ON

kgf/cm2

7.1

6.6

7.6

Pressure with S/T OFF

kPa

530

510

550

Pressure with S/T OFF

kgf/cm2

5.4

5.2

5.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure with S/T OFF

kPa

402

353

451

Pressure with S/T OFF

kgf/cm2

4.1

3.6

4.6

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1100

1100

1100

Pressure with S/T OFF

kPa

481

432

530

Pressure with S/T OFF

kgf/cm2

4.9

4.4

5.4

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

696

637

755

Pressure with S/T ON

kgf/cm2

7.1

6.5

7.7

Pressure with S/T OFF

kPa

530

501

559

Pressure with S/T OFF

kgf/cm2

5.4

5.1

5.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.6

4.1

5.1

Timer stroke with S/T OFF

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

900

900

900

Timer stroke with S/T OFF

mm

1.2

0.5

1.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T OFF

mm

2.2

1.6

2.8

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.6

3.9

5.3

Timer stroke with S/T OFF

mm

2.9

2.5

3.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

94

92

96

Timer stroke TA

mm

0.3

0

0.6

Timer stroke variation dT

mm

2.6

2.6

2.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

112

110

114

Timer stroke TA

mm

2.7

2.7

Timer stroke variation dT

mm

0.2

0.2

0.2

Oil temperature

degC

50

48

52

Remarks

(check)

(check)

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

94

91.5

96.5

Timer stroke TA

mm

0.3

0

0.8

Timer stroke variation dT

mm

2.6

2.6

2.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

25

22.5

27.5

Timer stroke TA

mm

3.5

2.7

4.3

Timer stroke variation dT

mm

0.6

0.6

0.6

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

30

25

35

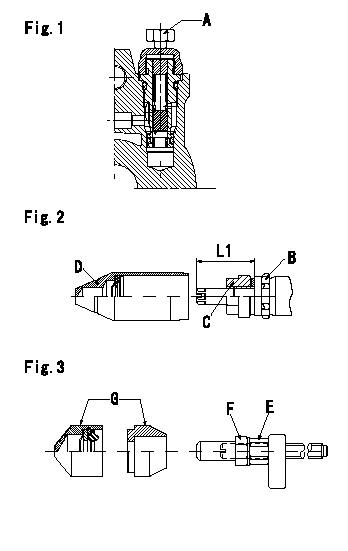

Test data Ex:

0000001801 TAMPER PROOF

Tamperproof installation procedure

A:Position of break

B:Rubber vibration damper

C:Nut

D:Cap

E:Nut

F:Nut

G:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Target breaking torque T1

2) Maximum allowable breaking torque T2

3) Because the cap and the regulating valve are fixed using the MEC process, the bolt cannot be loosened after the bolt has been broken.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T3.

Fig. 3 Maximum speed adjusting screw

1) Tighten nut (E) to the torque T4.

2) To prevent nut (E) from turning together, fix (E) using the tool, then tighten nut (F) to torque T4.

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

Have questions with 104742-3001?

Group cross 104742-3001 ZEXEL

Mitsubishi-Heav

104742-3001

F 01G 09W 0F9

32A6527310

INJECTION-PUMP ASSEMBLY

S4S-DT

S4S-DT