Rating:

Information injection-pump assembly

ZEXEL

104740-9601

1047409601

NISSAN-DIESEL

1670043G11

1670043g11

Cross reference number

ZEXEL

104740-9601

1047409601

NISSAN-DIESEL

1670043G11

1670043g11

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.3

51.8

52.8

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.9

7.4

14.4

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33.8

31.3

36.3

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

44.4

42.4

46.4

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.3

51.3

53.3

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51.4

49.4

53.4

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33.8

31.8

35.8

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

2

Boost compensator adjustment

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

17.8

16

19.6

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

431.5

402

461

Pressure

kgf/cm2

4.4

4.1

4.7

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

431.5

402

461

Pressure

kgf/cm2

4.4

4.1

4.7

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.5

2.3

2.7

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.5

2.2

2.8

_03

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

4.6

4

5.2

_04

Pump speed

r/min

2550

2550

2550

Timer stroke

mm

7.3

6.8

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

Test data Ex:

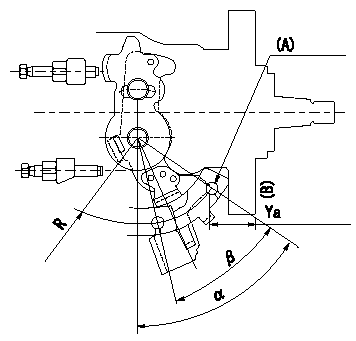

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension Ya between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle and lever reaction force measuring position

----------

Ya=24.3~28.7mm R=53mm

----------

Ya=24.3~28.7mm R=53mm Alpha=51.5~59.5deg Beta=31~41deg

----------

Ya=24.3~28.7mm R=53mm

----------

Ya=24.3~28.7mm R=53mm Alpha=51.5~59.5deg Beta=31~41deg

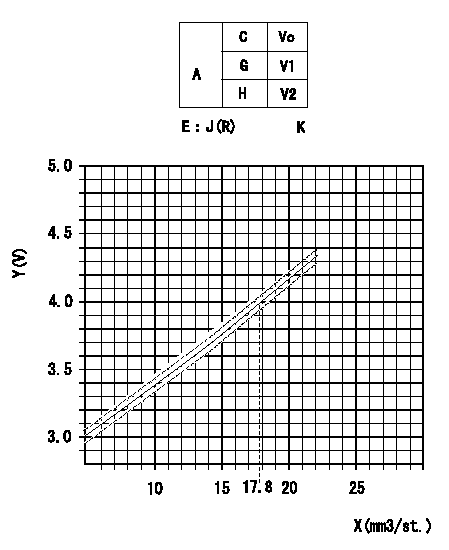

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula

G:Idling

H:Full speed

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:Confirm at least V3 at full lever position.

----------

N1=750r/min a=9.1+-0.5deg V3=6V L=6.0mm

----------

V1=-V V2=-V K=10V J:V=0.077X+2.63

----------

N1=750r/min a=9.1+-0.5deg V3=6V L=6.0mm

----------

V1=-V V2=-V K=10V J:V=0.077X+2.63