Rating:

Information injection-pump assembly

BOSCH

9 400 619 101

9400619101

ZEXEL

108621-2080

1086212080

MITSUBISHI

ME121249

me121249

Service parts 108621-2080 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

ME120897

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/24.5{250}

15.

NOZZLE SET

Include in #1:

108621-2080

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 101

9400619101

ZEXEL

108621-2080

1086212080

MITSUBISHI

ME121249

me121249

Zexel num

Bosch num

Firm num

Name

9 400 619 101

ME121249 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D40T1 K 14CP INJECTION PUMP ASSY TICS HD-TI6F TICS

6D40T1 K 14CP INJECTION PUMP ASSY TICS HD-TI6F TICS

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

21

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(12.9)

Vist

V

1.42

1.42

1.42

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

148.5

147.5

149.5

Max. variation between cylinders

%

0

-2

2

Basic

*

PS407980-224*

V

V1+1.44+

-0.01

PS407980-224*

mm

3.2+-0.0

5

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_02

Rack position

(6.5)

Vist

V

2.7

2.6

2.8

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

10.5

8.5

12.5

Max. variation between cylinders

%

0

-15

15

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Governor adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Governor adjustment_03

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

0000001201

Pre-stroke

mm

5.6

5.57

5.63

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

5

4.5

5.5

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1

1

1.05

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.6

2.32

2.88

Output voltage

V

2.8

2.78

2.87

Confirmation

*

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

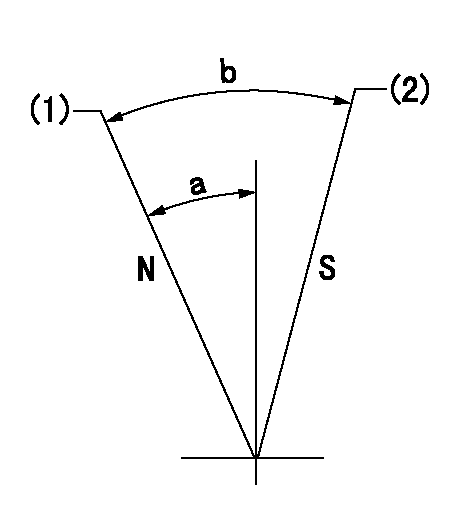

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

0000000901

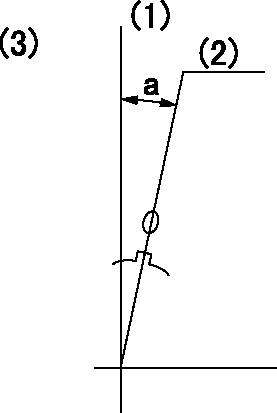

(1)Pump vertical direction

(2)Position of the coupling key groove at the start of injection for the No. 1 cylinder

(3)At pre-stroke aa

----------

aa=5.6+-0.03mm

----------

a=(2deg)

----------

aa=5.6+-0.03mm

----------

a=(2deg)

0000001701

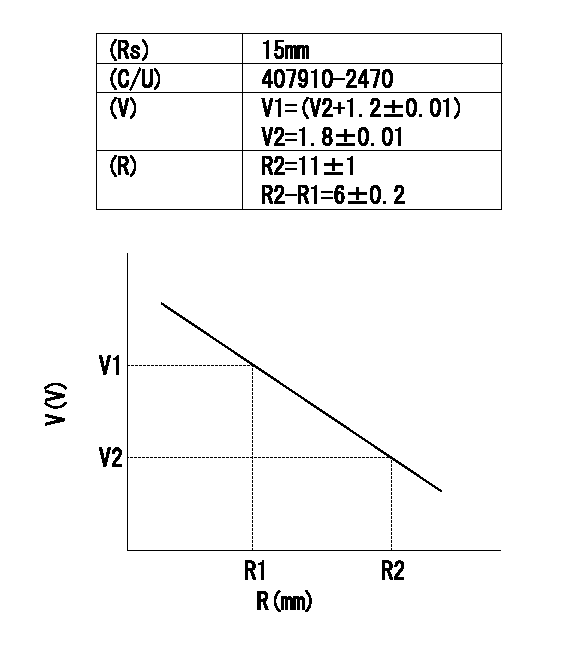

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

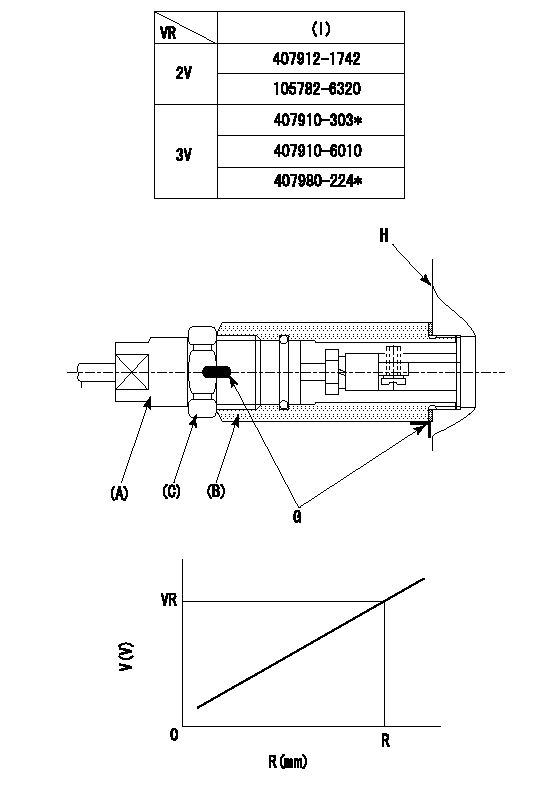

0000001901 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (154610-0620)

(1)At governor side rack sensor output voltage V1, adjust the bobbin (A) so that the drive side rack sensor output voltage is VR+-0.01.

(2)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

V1=1V

----------

----------

V1=1V

----------