Rating:

Information injection-pump assembly

BOSCH

9 400 616 756

9400616756

ZEXEL

106671-2641

1066712641

MITSUBISHI

ME056309

me056309

Cross reference number

BOSCH

9 400 616 756

9400616756

ZEXEL

106671-2641

1066712641

MITSUBISHI

ME056309

me056309

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

8.1

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

109

106.3

111.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.1)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

109

108

110

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(8.1)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

123

119

127

Difference in delivery

mm3/st.

8

8

8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_06

Adjusting point

E

Rack position

10.5++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

105

145

Fixing the lever

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

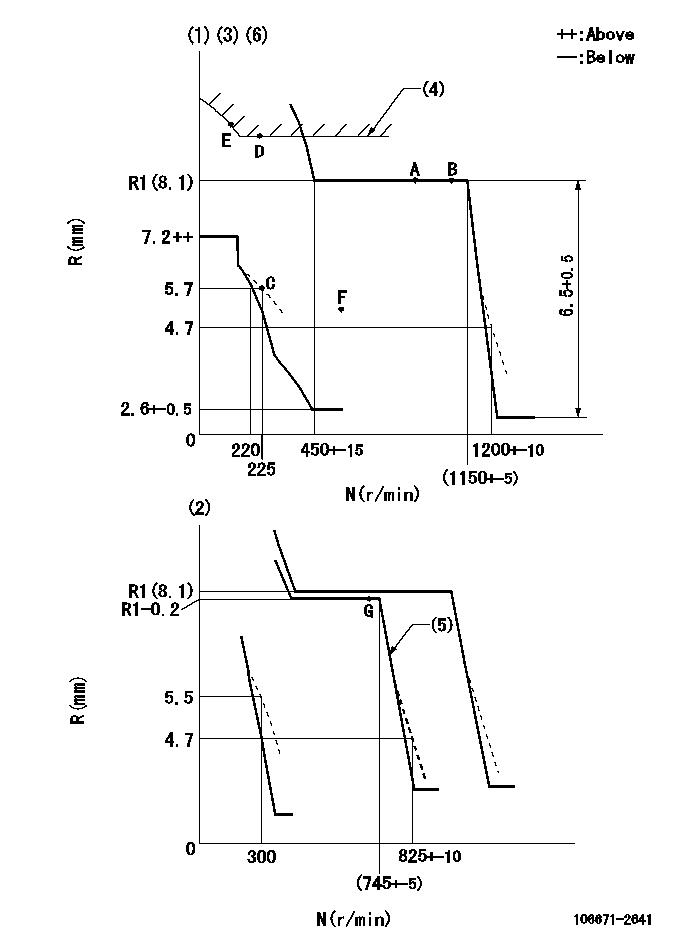

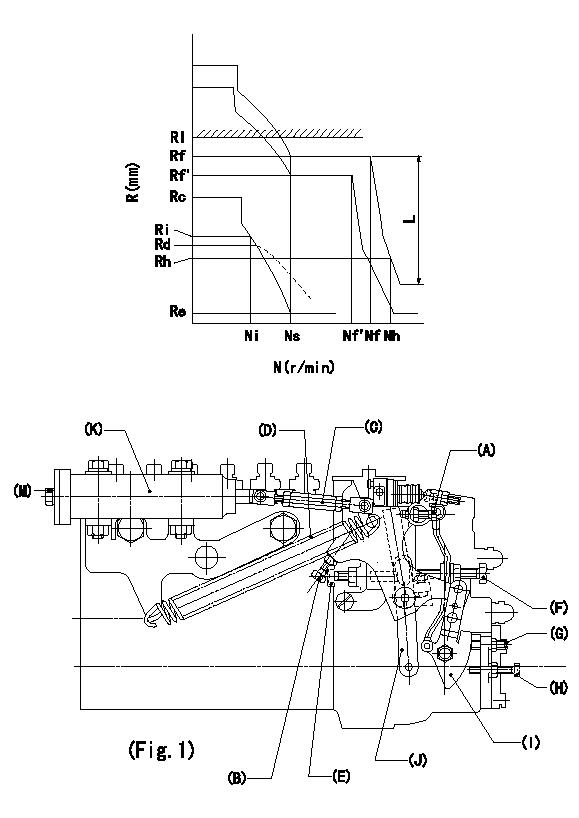

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Adjust with the load control lever in the full position (variable speed specification).

(3)Target shim dimension: TH

(4)Excess fuel setting for starting: SXL

(5)When air cylinder is operating.

(6)Beginning of damper spring operation: DL

----------

TH=2.4mm SXL=10.5+-0.1mm DL=6-0.2mm

----------

----------

TH=2.4mm SXL=10.5+-0.1mm DL=6-0.2mm

----------

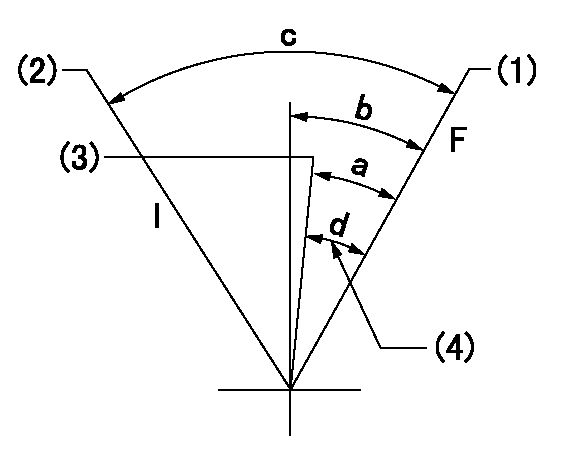

Speed control lever angle

F:Full speed

I:Idle

(1)When pump speed set at aa

(2)When pump speed set at bb

(3)Pump speed cc

(4)Possible adjusting range

----------

aa=1150r/min bb=300r/min cc=750r/min

----------

a=10deg+-5deg b=10deg+-5deg c=22deg+-5deg d=10deg

----------

aa=1150r/min bb=300r/min cc=750r/min

----------

a=10deg+-5deg b=10deg+-5deg c=22deg+-5deg d=10deg

0000000901

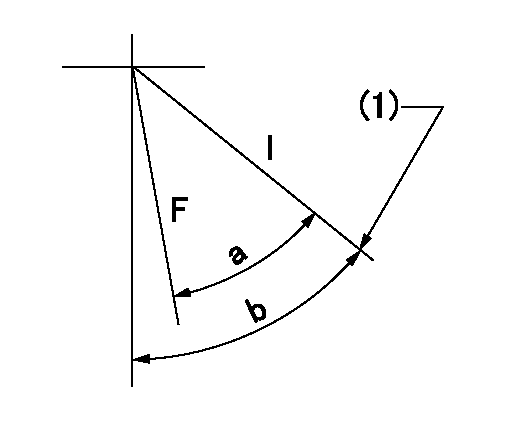

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=20deg+-3deg b=21deg+-5deg

----------

----------

a=20deg+-3deg b=21deg+-5deg

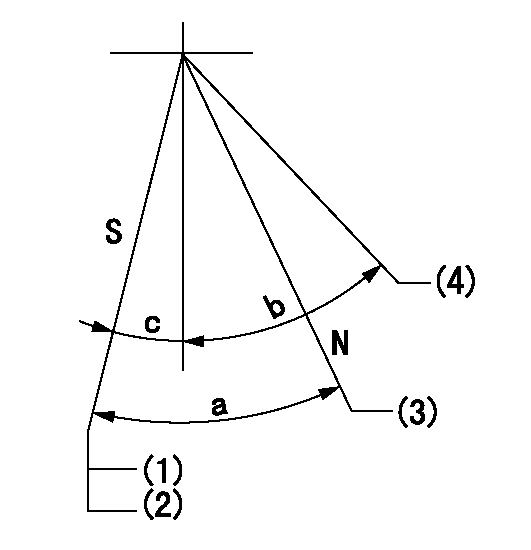

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Stopper bolt setting

(2)Rack position = aa

(3)Rack position bb

(4)Free (at shipping)

----------

aa=4.1-0.5mm bb=13.1mm

----------

a=27deg+-5deg b=(56deg)+-5deg c=0deg+7deg-5deg

----------

aa=4.1-0.5mm bb=13.1mm

----------

a=27deg+-5deg b=(56deg)+-5deg c=0deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

0000001601 2-STAGE CHANGEOVER DEVICE

RFD governor 2 stage changeover mechanism adjustment outline

(A) Bolt

(B) bolt

(c) Nut

(D) Return spring

(E) Bolt

(F) Bolt

(G) Screw

(H) Bolt

(I) Load lever

(J) Speed lever

(K) Air cylinder

(M Air inlet

Figure 1 is only for reference. Lever shape, etc, may vary.

1. Minimum-maximum speed specification adjustment (when running)

(a) Without applying air to the air cylinder, loosen bolts (A) and (B).

(1)High speed return L setting

(a) In the speed range Nf~Nf - 300r/min, adjust using the speed adjusting bolt to determine the temporary beginning of high speed control speed.

(b) Determine the rack position in the vicinity of Rf using the full load lever.

(c) Increase speed and confirm return distance L.

(d) Adjust using the tension lever bolt to obtain L.

(2)Setting full load rack position Rf

(a) Move the load control lever to the full side.

(b) Adjust the full load adjusting bolt so that Rf can be obtained, then fix.

(3)Setting the beginning of high speed operation Nf

(a) Adjust using bolt (E) so that Nf can be obtained, and then fix.

(4)Idle control setting (Re, Ni, Rc)

(a) Set the speed at Ns + 200r/min and move the load control lever to the idle side.

(b) Fix the lever in the position where Re can be obtained.

(c) Next, decrease speed to Ni and screw in the idle spring.

(d) Adjust to obtain rack position Ri.

(e) Increase the speed and after confirming that the rack position is Re at Ns, set the speed at 0.

(f) Confirm protrusion position Rc at idle.

(5)Damper spring adjustment

(a) Increase speed and set the speed at the rack position Rd - 0.1 mm

(b) Set using the damper spring so that the rack position Rd can be obtained.

(c) When Rd is not specified, Rd = Ri - 0.5 mm.

(6)High speed droop confirmation

(a) Return the load control lever to the full load lever position.

(b) Increase the speed and confirm that Rf can be obtained at Nf r/min.

(c) Confirm that speed is Nh at rack position Rh.

2. Variable speed specification adjustment (at operation)

(a) Remove return spring (D).

(b) Apply air pressure of 245~294 kPa {2.5~3 kg/cm2} to the air cylinder.

(c) Perform the following adjustment in this condition.

(1)Setting full load rack position Rf'

(a) Pull the load lever to the idle side.

(b) Obtain rack position Rf' using the nut (C). (Pump speed is Nf'-50 r/min.)

(2)Setting full speed Nf'

(a) Adjust using bolt (B) so that Nf can be obtained, and then fix.

(3)Low speed side setting

(a) At 350r/min, set bolt (F) at beginning of governor operation position, then fix.

3. Bolt (A) adjustment

(1)Install return spring (D) and perform the adjustments below at air pressure 0.

(a) Set at speed Nf using bolt (E).

(b) Screw in bolt (A).

(c) Screw in 1 more turn from the speed lever contact position

(d) Fix bolt (A).

(e) At this time confirm that the air cylinder's shaft moves approximately 1 mm towards the governor.

4. Lever operation confirmation using the air cylinder

(1)Apply 588 kPa {6 kg/cm2} air pressure to the air cylinder.

(2)Confirm that the cylinder piston is moved 50 mm by the spring (D).

----------

----------

----------

----------