Rating:

Information injection-pump assembly

BOSCH

9 400 616 594

9400616594

ZEXEL

106661-2111

1066612111

MITSUBISHI

ME056852

me056852

Cross reference number

BOSCH

9 400 616 594

9400616594

ZEXEL

106661-2111

1066612111

MITSUBISHI

ME056852

me056852

Zexel num

Bosch num

Firm num

Name

106661-2111

9 400 616 594

ME056852 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T2 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T2 * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-6920

Overflow valve opening pressure

kPa

191

157

225

Overflow valve opening pressure

kgf/cm2

1.95

1.6

2.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

149

145.3

152.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

11.5

9.8

13.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

148

150

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.35

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

147.5

145.5

149.5

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_05

Adjusting point

E

Rack position

R1+1.25

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

174

170

178

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_06

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

131

91

171

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R2(R1-1.

7)

Boost pressure

kPa

6

6

6

Boost pressure

mmHg

45

45

45

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1-0.8

Boost pressure

kPa

10

8.7

11.3

Boost pressure

mmHg

75

65

85

Boost compensator adjustment_03

Pump speed

r/min

700

700

700

Rack position

R1(10.6)

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

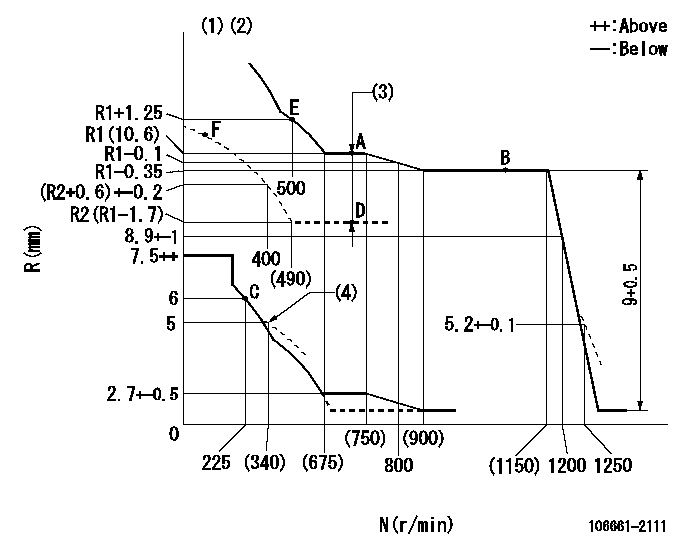

Test data Ex:

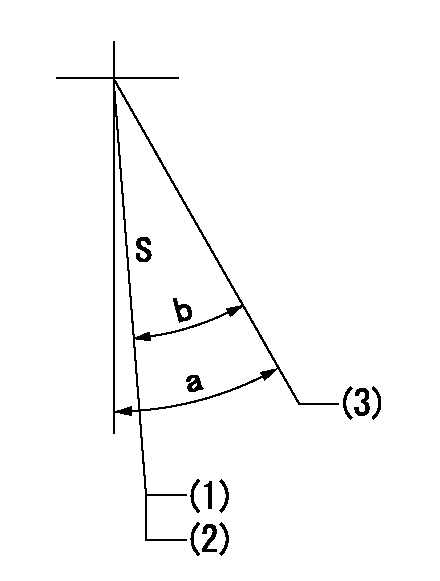

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator cancel stroke: BSL

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

BSL=1.8mm BCL=1.7+-0.1mm

----------

----------

BSL=1.8mm BCL=1.7+-0.1mm

----------

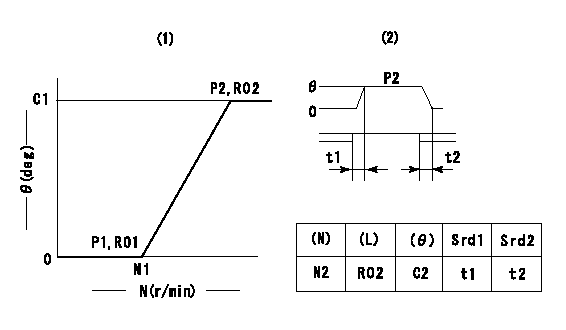

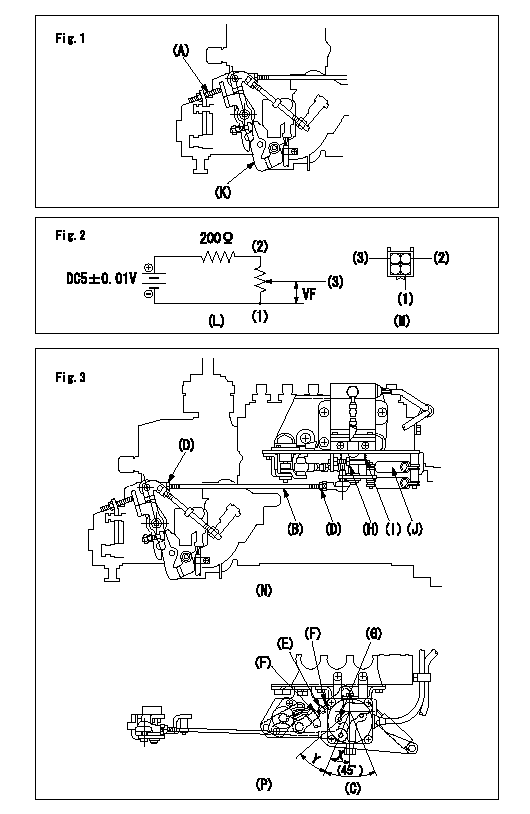

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

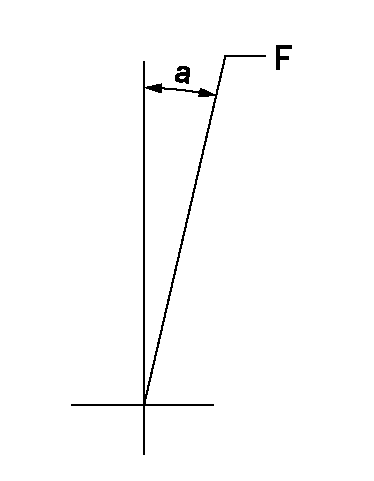

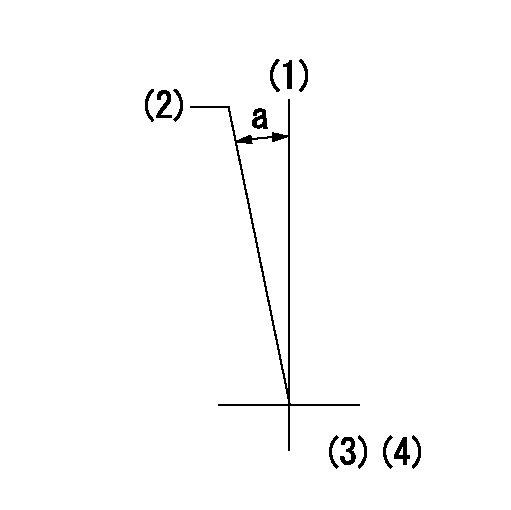

Speed control lever angle

F:Full speed

----------

----------

a=14.5deg+-5deg

----------

----------

a=14.5deg+-5deg

0000000901

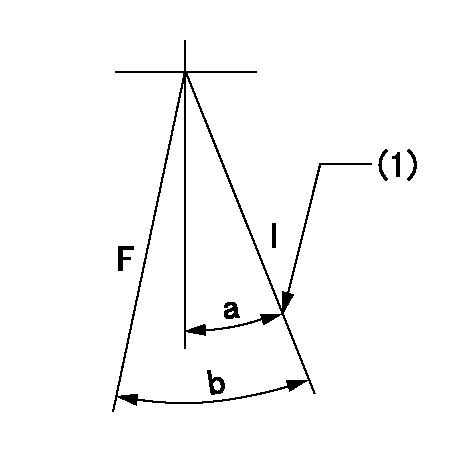

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=29.5deg+-3deg

----------

----------

a=28deg+-5deg b=29.5deg+-3deg

Stop lever angle

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Free (at shipping)

----------

aa=3.8-0.5mm

----------

a=38deg+-5deg b=37.5deg+7deg-5deg

----------

aa=3.8-0.5mm

----------

a=38deg+-5deg b=37.5deg+7deg-5deg

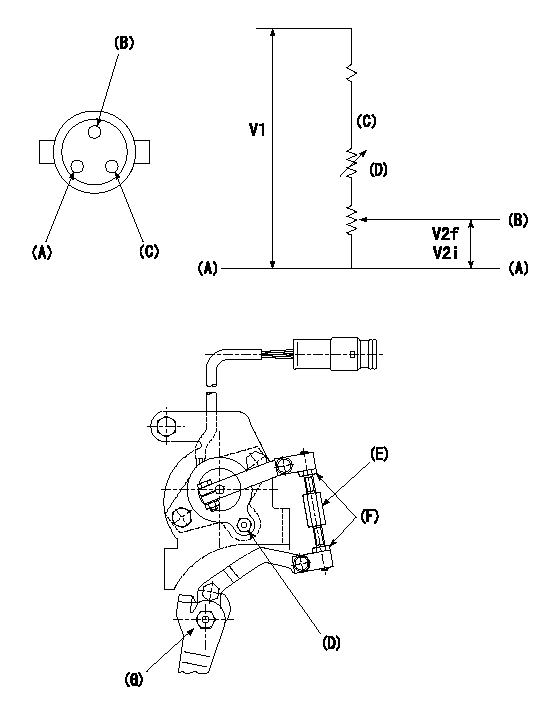

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.7+-0.1mm

----------

----------

N1=325r/min Ra=5.7+-0.1mm

----------

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

0000001701 LEVER

(A) Stopper bolt

(B) Link

(C) S/M lever

(d) Nut

(E) Ring

(F) Nut

(G) S/M lever pin

(H) Stopper bolt

(I) Torsion spring

(J) Return spring

(K) Accelerator lever

(L) Output measurement circuit

(M) Potentiometer terminal

(N) Viewed from front.

(P) Viewed from top.

(1)Black

(2)Blue-red

(3)Blue-yellow

Accelerator lever angle, potentiometer and stopper bolt adjustment

1. Accelerator lever angle adjustment (see Fig. 1)

(1)Hold the load lever against the idle side stopper bolt and fix it in the idling position.

(2)Screw in the accelerator lever stopper bolt (A) and back off the stopper bolt (A) from the position where the accelerator lever contacts the load lever and fix the nut.

Tightening torque: 4.9~7 N.m (0.5~0.7 kgf.m)

2. Potentiometer adjustment (See fig 2 and fig 3)

Apply DC5+-0.01V to between the potentiometer terminals (2) ~ (1) and measure the output voltage VF between (3) ~ (1).

(1)Hold the load lever against the idle side stopper bolt and fix it in the idling position.

(2)Adjust the S/M lever (C)'s lever angle using the link (B) so that X = 22.5+-3 deg , then fix nut (D).

Tightening torque: 3.4~4.9 N.m (0.35~0.5 kgf.m)

(3)Hold the load lever against the full side stopper bolt and fix it in the full position.

(4)Adjust the potentiometer output voltage using the link (E) so that VF = 0.25+-0.1V, the temporarily fix nut (F).

(5)Move the load lever several times between the idle side and the full side. Confirm that it moves smoothly and that output voltage VF = 0.05~0.5V. Then fix nut (F).

Tightening torque: 3.4~4.9 N.m (0.35~0.5 kgf.m)

3. Step motor's idle side stopper bolt adjustment (See fig 3)

(1)After completing accelerator lever angle and potentiometer adjustment, position the load lever against the idle stopper bolt and fix in the idling position.

(2)Screw in stopper bolt (H) until the S/M lever pin (G) contacts the lever (C).

(3)Return the stopper bolt (H) 10 deg+2 deg (approx. 5.7 turns) from the position in (2) above and fix using the nut.

(Reference: lever angle Y = 39.5deg+2deg

Tightening torque: 4.9~7 N.m (0.5~0.7 kgf.m)

4. Final confirmation

Confirm that the load lever is returned to the idling position through the torsion spring (I) and one return spring (J). (Remove 1 return spring.)

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(7deg)

----------

aa=9deg

----------

a=(7deg)

Have questions with 106661-2111?

Group cross 106661-2111 ZEXEL

Mitsubishi

Mitsubishi

106661-2111

9 400 616 594

ME056852

INJECTION-PUMP ASSEMBLY

6D22T2

6D22T2