Rating:

Information injection-pump assembly

ZEXEL

104760-4092

1047604092

NISSAN-DIESEL

1670006J05

1670006j05

Cross reference number

ZEXEL

104760-4092

1047604092

NISSAN-DIESEL

1670006J05

1670006j05

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

50.9

50.4

51.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

52

50

54

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

50.9

49.9

51.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

44.7

42.6

46.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.6

18.6

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

43.5

39

48

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

16.6

14.1

19.1

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.8

10.8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.8

6.3

11.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

80

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

400

270

530

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

402

382

422

Pressure

kgf/cm2

4.1

3.9

4.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

402

373

431

Pressure

kgf/cm2

4.1

3.8

4.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

598

559

637

Pressure

kgf/cm2

6.1

5.7

6.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.4

1.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1.3

1.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.8

5.3

6.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.64

6.54

6.74

MS dimension

mm

1

0.9

1.1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

40

35

45

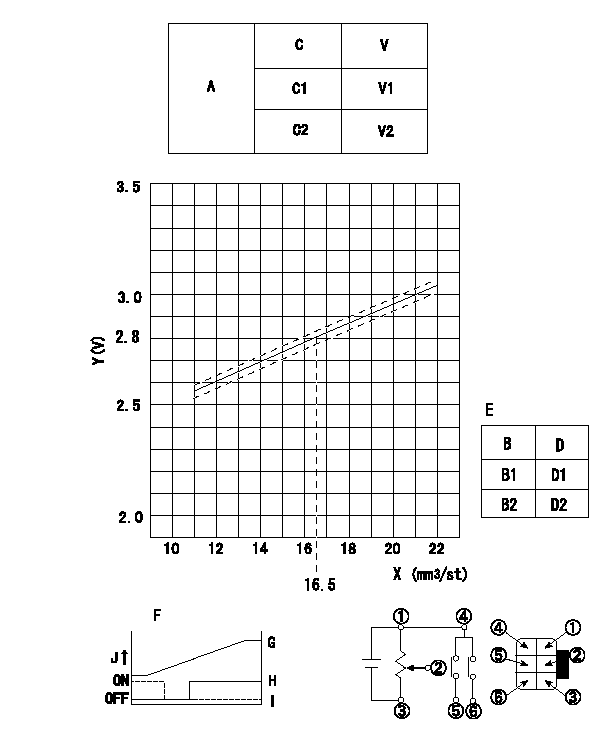

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N1 and a control lever position a from idle (gap L1), measure the injection quantity and convert it to a voltage value. Then adjust the potentiometer.

Voltage conversion formula: V+-0.03 = 0.044Q+2.07

A:Potentiometer performance standards

C:Position of the control lever

C1:Idle

C2:Full speed

V:Potentiometer voltage

E:Standards for the potentiometer's ON - OFF switch

B:Conversion point

B1:OFF-->ON

B2:OFF-->ON

D:Lever opening (from idle)

Vi:Applied voltage

F:Connecting diagram for the potentiometer

G:Output when (2) and (3) connected.

H:When (4) or (6) connected: switch OFF to ON.

I:When (4) or (5) connected: switch ON to OFF.

J:Output

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V Vi=10V D1=6.0+-3.5deg D2=29.0+-3.5deg

----------

N1=700r/min a=7.5deg L1=4.9mm Vi=10V

----------

V1=1.6+-0.4V V2=8.0+-0.55V Vi=10V D1=6.0+-3.5deg D2=29.0+-3.5deg