Rating:

Information injection-pump assembly

ZEXEL

104748-2570

1047482570

Cross reference number

ZEXEL

104748-2570

1047482570

Zexel num

Bosch num

Firm num

Name

104748-2570

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

27.6

27.1

28.1

Difference in delivery

mm3/st.

2

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.8

11.3

18.3

Injection timing adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

26.3

24.3

28.3

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

27.6

26.6

28.6

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

26.8

24.8

28.8

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14.8

11.8

17.8

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

6

Governor adjustment

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.1

6.6

9.6

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

8.1

6.1

10.1

Governor adjustment_03

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

5

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

15.3

10.8

19.8

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55.3

50.3

60.3

Basic

*

Remarks

Refer to additional devices.

Refer to additional devices.

Speed control lever angle

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1200

1200

1200

Overflow quantity

cm3/min

348

216

480

Stop lever angle

Pump speed

r/min

1200

1200

1200

Pressure

kPa

372.5

343

402

Pressure

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1200

1200

1200

Pressure

kPa

372.5

333

412

Pressure

kgf/cm2

3.8

3.4

4.2

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

510

471

549

Pressure

kgf/cm2

5.2

4.8

5.6

Stop lever angle_04

Pump speed

r/min

2500

2500

2500

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

0000001101

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

2.9

2.6

3.2

Basic

*

_02

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

2.9

2.5

3.3

_03

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5.4

5

5.8

_04

Pump speed

r/min

2500

2500

2500

Timer stroke

mm

8.15

7.7

8.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

16.5

15.5

17.5

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.6

1.5

1.7

Control lever angle alpha

deg.

0

-1

1

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

11

10.5

11.5

Test data Ex:

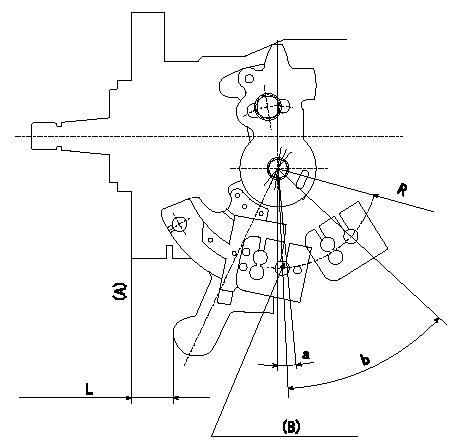

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure the dimension L from the lever tip to the flange face (A).

2. Measure the lever angle from the pin hole R (plate).

(B): lever angle measuring hole

Alpha = a

beta: b

----------

R=44mm L=15.4~18.1mm

----------

R=44mm L=15.4~18.1mm a=1~-1deg b=37~47deg

----------

R=44mm L=15.4~18.1mm

----------

R=44mm L=15.4~18.1mm a=1~-1deg b=37~47deg

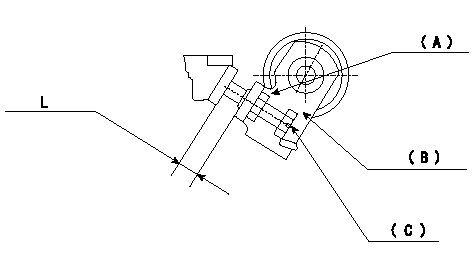

0000001901 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust adjusting bolt so that the starting injection quantity is within the standard.

Fix using nut.

(A): Lock nut.

(B): Stopping lever

(C): Adjustment bolt

----------

----------

L=5.9~8.2mm

----------

----------

L=5.9~8.2mm

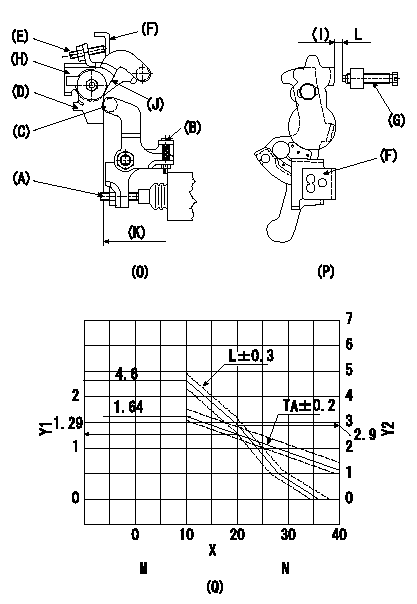

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Timer advance adjustment (refer to Fig 1 [O], 3 [Q]).

(1)Determine the timer advance angle from the graph in Fig. 3 (Q).

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

2. Setting the intermediate lever position (refer to fig 1 and fig 2)

(1)Insert a block gauge L1 between the idling set screw (G) and the control lever (F).

(2)Align the intermediate lever (D) with the aligning line (J) and position it perpendicularly.

3. W-CSD lever adjustment [refer to fig 1 (O) and fig 2 (P)]

(1)After completing (2) above, remove the block gauge L2.

(2)Insert a block gauge (I) L3 determined from the graph (L-theta) in figure 3 (Q) between the idling set screw (G) and the control lever (F).

(3)Fix screw (B) so that the W-CSD lever (C)'s roller contacts the intermediate lever (D). Fix using the nut.

Note:

The temperature of the wax at adjustment must not exceed a.

X:Temperature theta (deg C)

Y1:Timer stroke TA (mm)

Y2:Control lever L dimension (mm; control lever position)

K:Vertical position

M:TA-theta line

10 <= theta (deg C) <= 20: TA = -0.0355 theta + 1.995

20 <= theta (deg C) <= 57: TA = -0.03515 theta + 1.988

N:L-theta graph

theta (deg C) <= 10: L = 4.6

10 < theta (deg C) <= 20: L = -0.17theta + 6.3

20 < theta (deg C) <= 28.5: L = -0.235 theta + 7.6

28.5 < theta (deg C) <= 36: L = -0.012 theta + 4.32

----------

L1=L=2.9+-0.05mm L2=2.9mm L3=L+-0.05mm a=30degC

----------

----------

L1=L=2.9+-0.05mm L2=2.9mm L3=L+-0.05mm a=30degC

----------

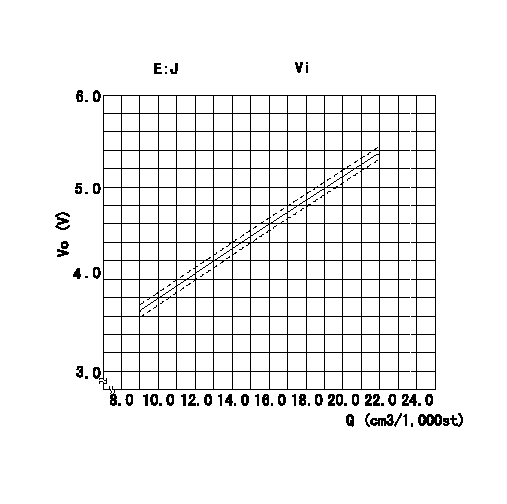

0000002101 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N = N1 r/min and with the control lever angle at a from the idle position (corresponding to a shim thickness of L mm), convert the injection quantity obtained to a voltage value using the graph and adjust the potentiometer.

Vi:Applied voltage

E = conversion expression

Vo = output voltage

Q = injection quantity

----------

N1=700r/min a=12+-0.5deg L=-mm Vi=10V

----------

J+-0.03=0.1352Q+2.42(V) Vi=10V

----------

N1=700r/min a=12+-0.5deg L=-mm Vi=10V

----------

J+-0.03=0.1352Q+2.42(V) Vi=10V

Have questions with 104748-2570?

Group cross 104748-2570 ZEXEL

Nissan

104748-2570

INJECTION-PUMP ASSEMBLY