Rating:

Information injection-pump assembly

ZEXEL

104746-6591

1047466591

ISUZU

8971918611

8971918611

Cross reference number

ZEXEL

104746-6591

1047466591

ISUZU

8971918611

8971918611

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

58.1

57.6

58.6

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

33.1

29.6

36.6

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

44.2

40.7

47.7

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

58.1

57.1

59.1

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

64.3

60.3

68.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33.6

30.6

36.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33.6

30.6

36.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

100

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

630

500

760

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

412

392

432

Pressure

kgf/cm2

4.2

4

4.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure

kPa

412

392

432

Pressure

kgf/cm2

4.2

4

4.4

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

2.7

2.5

2.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

2.7

2.5

2.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

3.9

3.5

4.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2050

2050

2050

Timer stroke

mm

5.3

5

5.7

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.8

0.7

0.9

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

35

30

40

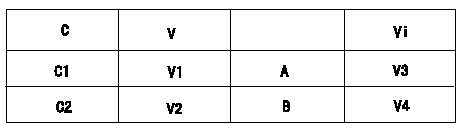

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Adjusting point

B:Confirmation point

C:Lever position

Vi:Applied voltage

V:Output voltage

C1:Idle

C2:Full speed

----------

----------

V1=1.2+-0.03V V2=(7.03+-0.86)V V3=10V V4=10V

----------

----------

V1=1.2+-0.03V V2=(7.03+-0.86)V V3=10V V4=10V

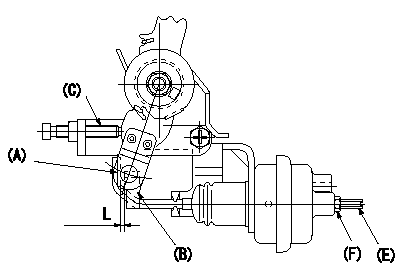

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. After installing the V-FICD, apply P1 (kPa) {P2 (mmHg)} to the actuator and confirm that it moves through its full stroke.

2. After release, confirm that the clearance between (A) and (B) is L (mm).

----------

L=1+1(mm) P1=-53.3(kPa) P2=-400(mmHg)

----------

L=1+1(mm)

----------

L=1+1(mm) P1=-53.3(kPa) P2=-400(mmHg)

----------

L=1+1(mm)

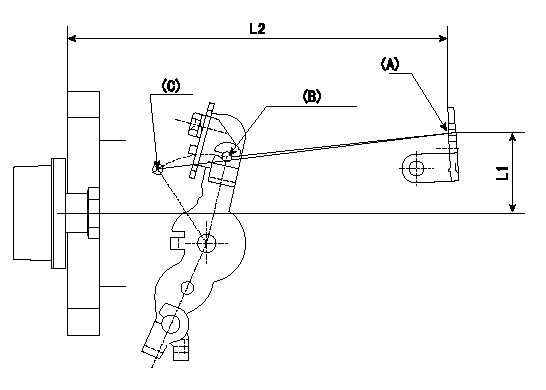

0000002001 A/T PLATE ADJUSTMENT

A/T plate adjustment

Adjust the A/T plate (A) so that (A)(C) - (A)(B) = L3 when the control lever is moved from the idle position (B) to the full speed position (C), then fix.

(B) Idle position

(C) Full

----------

L3=34+-1mm

----------

L1=41mm L2=173.2mm SW=SW8 T=3.4~4.9N-m(0.35~0.5kgf-m)

----------

L3=34+-1mm

----------

L1=41mm L2=173.2mm SW=SW8 T=3.4~4.9N-m(0.35~0.5kgf-m)