Rating:

Information injection-pump assembly

BOSCH

9 460 613 498

9460613498

ZEXEL

104741-7082

1047417082

Cross reference number

BOSCH

9 460 613 498

9460613498

ZEXEL

104741-7082

1047417082

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

50

49.5

50.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

48

46

50

Injection timing adjustment_02

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

50.6

47.1

54.1

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

50

49

51

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

58.7

55.7

61.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

63.8

60.3

67.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

12

8

16

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

12

7.5

16.5

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.7

6.7

10.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

3

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8.7

6.2

11.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

77.6

72.6

82.6

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

77.6

72.6

82.6

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

340

210

470

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

324

304

344

Pressure

kgf/cm2

3.3

3.1

3.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

324

295

353

Pressure

kgf/cm2

3.3

3

3.6

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

0.9

0.7

1.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

0.5

0

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

0.9

0.6

1.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

1.2

0.7

1.7

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

32

27

37

Test data Ex:

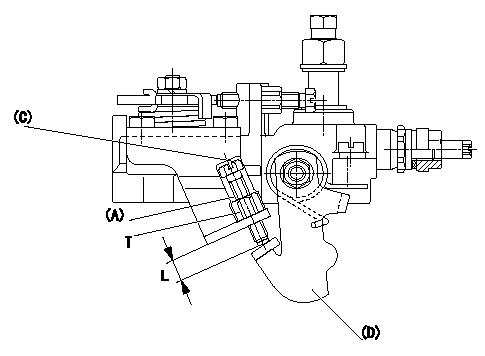

0000001801 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (B) protrusion: L

(C) = Cap

(D) = Stop lever

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)