Rating:

Information injection-pump assembly

ZEXEL

104741-6781

1047416781

ISUZU

8970134681

8970134681

Cross reference number

ZEXEL

104741-6781

1047416781

ISUZU

8970134681

8970134681

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.7

41.2

42.2

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

38.3

38.3

38.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

34.4

34.4

34.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.7

40.7

42.7

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

43.9

40.9

46.9

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

47.5

44

51

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

10.6

7.6

13.6

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

10.6

7.6

13.6

Difference in delivery

mm3/st.

4

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

5.5

3.5

7.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

5.5

3.5

7.5

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity with S/T ON

cm3/min

490

360

620

Overflow quantity with S/T OFF

cm3/min

580

450

710

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

451

431

490

Pressure with S/T OFF

kgf/cm2

4.6

4.4

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

451

431

490

Pressure with S/T OFF

kgf/cm2

4.6

4.4

5

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke with S/T ON

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T OFF

mm

7

6.7

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

31

26

36

Test data Ex:

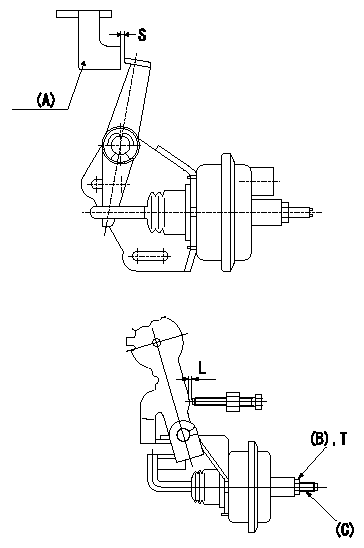

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust to obtain S.

2. Confirm that L1 is obtained when negative pressure P1 (P2 ) is applied to the actuator.

To adjust the stroke adjust the actuator's stroke adjusting screw (C).

(A) Control lever

(B) Lock nut (Tightening torque T)

(C) Stroke adjusting screw

----------

S=2+1mm L=0.7+-0.2mm P1=-46.7kPa P2=-350mmHg

----------

S=2+1mm L=0.7+-0.2mm T=1.2~1.5N-m{0.12~0.15kgf-m}

----------

S=2+1mm L=0.7+-0.2mm P1=-46.7kPa P2=-350mmHg

----------

S=2+1mm L=0.7+-0.2mm T=1.2~1.5N-m{0.12~0.15kgf-m}

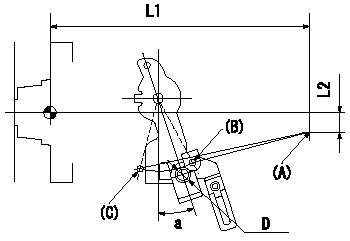

0000001901 A/T PLATE ADJUSTMENT

A/T plate adjustment

Rotate the control lever from the idle position (B) to the full-speed position (C).

Adjust the A/T plate (A) so that (A) (C) - (A) (B) = L3, and fix.

When fixing, fix the A/T plate outside the range diameter 9.2 mm from the center of the control lever's wire hole (hole dia. 8.5 mm).

(B): B idle position

(C): B' full

----------

L3=32.9+-1mm

----------

L1=169.8mm L2=12.4mm a=18+-4deg D=Dia.9.2mm

----------

L3=32.9+-1mm

----------

L1=169.8mm L2=12.4mm a=18+-4deg D=Dia.9.2mm

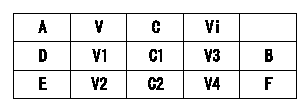

0000002001 POTENTIOMETER ADJUSTMENT

A = lever position

B = adjusting point

Vi = applied voltage

V = output voltage

C = lever angle

D = full speed

E = idle

F = confirmation point

----------

----------

V1=8.2+-0.03V V2=3.94 or less V C1=31+-5deg C2=0deg V3=10V V4=10V

----------

----------

V1=8.2+-0.03V V2=3.94 or less V C1=31+-5deg C2=0deg V3=10V V4=10V