Rating:

Information injection-pump assembly

ZEXEL

104740-2373

1047402373

NISSAN

167001C310

167001c310

Cross reference number

ZEXEL

104740-2373

1047402373

NISSAN

167001C310

167001c310

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.8

31.3

32.3

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

Full

Full

Injection timing adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

43.35

42

44.7

Boost pressure

mmHg

325

315

335

Average injection quantity

mm3/st.

45.1

44.6

45.6

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

2700

2700

2700

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

21.4

13.9

28.9

Injection timing adjustment_04

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

37.5

36

39

Injection timing adjustment_05

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

45.9

42.4

49.4

Injection timing adjustment_06

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

47.6

44.1

51.1

Injection timing adjustment_07

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

51.3

48.3

54.3

Injection timing adjustment_08

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

51.6

48.6

54.6

Injection timing adjustment_09

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

31.8

30.8

32.8

Remarks

Full

Full

Injection timing adjustment_10

Pump speed

r/min

900

900

900

Boost pressure

kPa

43.35

42

44.7

Boost pressure

mmHg

325

315

335

Average injection quantity

mm3/st.

45.1

44.1

46.1

Remarks

CBS

CBS

Injection timing adjustment_11

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

35.7

33.7

37.7

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

37.5

36.5

38.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2950

2950

2950

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

6

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

10.5

9.5

11.5

Basic

*

Governor adjustment_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Governor adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

10.5

9

12

Boost compensator adjustment

Pump speed

r/min

700

700

700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.4

11.9

24.9

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

65

60

70

Basic

*

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Overflow quantity

cm3/min

378

246

510

Stop lever angle

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

382.5

353

412

Pressure

kgf/cm2

3.9

3.6

4.2

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

313.5

284

343

Pressure

kgf/cm2

3.2

2.9

3.5

Stop lever angle_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

382.5

353

412

Pressure

kgf/cm2

3.9

3.6

4.2

Stop lever angle_04

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

490.5

461

520

Pressure

kgf/cm2

5

4.7

5.3

Stop lever angle_05

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

0000001101

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

3

2.8

3.2

Basic

*

_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

1

0.3

1.7

_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

3

2.7

3.3

_04

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

5.9

5.4

6.4

_05

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

8.2

7.6

8.8

_06

Pump speed

r/min

2200

2200

2200

Boost pressure

kPa

66.65

65.3

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

8.9

8.4

9.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.9

25.4

26.4

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

25.9

24.9

26.9

Timer stroke variation dT

mm

0.35

0

0.7

_03

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

17.5

16

19

Timer stroke variation dT

mm

0.8

0.3

1.3

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.29

6.19

6.39

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.6

4.4

4.8

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

9

8.5

9.5

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

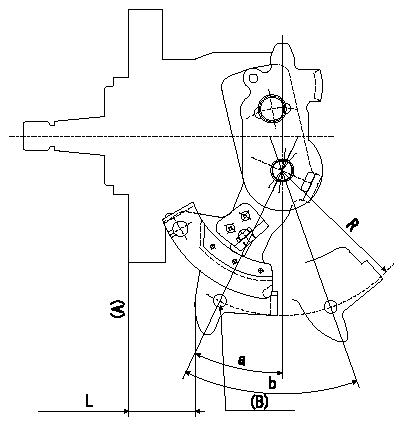

1. Measure the dimension L from the lever tip to the flange face (A).

2. Measure the lever angle from the pin hole R (plate).

(B): lever angle measuring hole

Alpha = a

beta: b

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

----------

R=61.5mm L=25.7~29.7mm

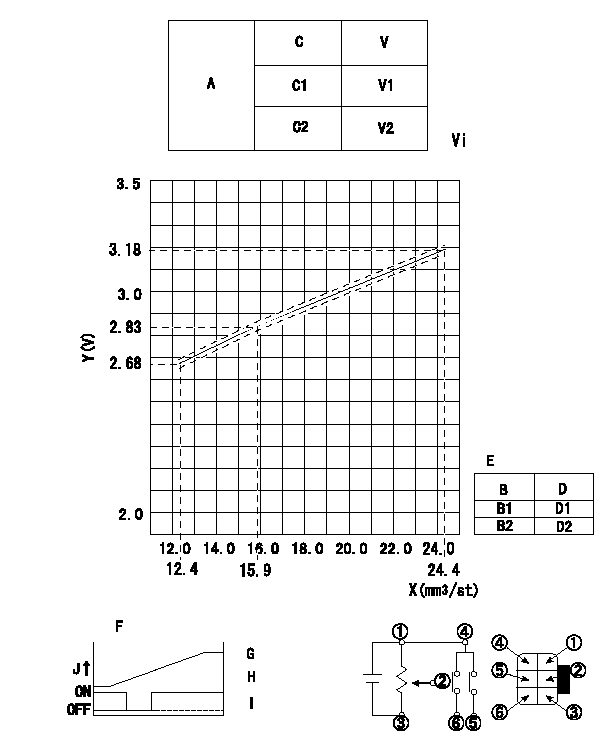

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

At pump speed N1 and a control lever position a from idle (gap L1), measure the injection quantity and convert it to a voltage value. Then adjust the potentiometer.

Voltage conversion formula: V+-0.03 = 0.04163Q+2.1637

A:Potentiometer performance standards

C:Position of the control lever

C1:Idle

C2:Full speed

V:Potentiometer voltage

E:Standards for the potentiometer's ON - OFF switch

B:Conversion point

B1:OFF-->ON

B2:OFF-->ON

D:Lever opening (from idle)

Vi:Applied voltage

F:Connecting diagram for the potentiometer

G:Output when (2) and (3) connected.

H:When (4) or (6) connected: switch OFF to ON.

I:When (4) or (5) connected: switch ON to OFF.

J:Output

----------

N1=700r/min a=9deg L1=5.95mm

----------

V1=1.43+-0.4V V2=8.43+-1.47V Vi=10V D1=5+-3deg D2=21.5++deg

----------

N1=700r/min a=9deg L1=5.95mm

----------

V1=1.43+-0.4V V2=8.43+-1.47V Vi=10V D1=5+-3deg D2=21.5++deg

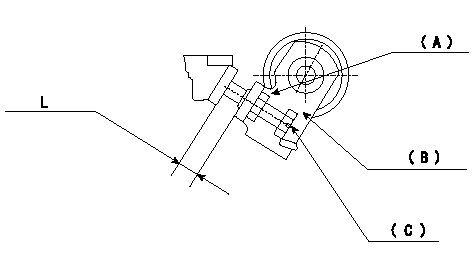

0000002001 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust adjusting bolt so that the starting injection quantity is within the standard.

Fix using nut.

(A): Lock nut.

(B): Stopping lever

(C): Adjustment bolt

----------

----------

L=5~10mm

----------

----------

L=5~10mm

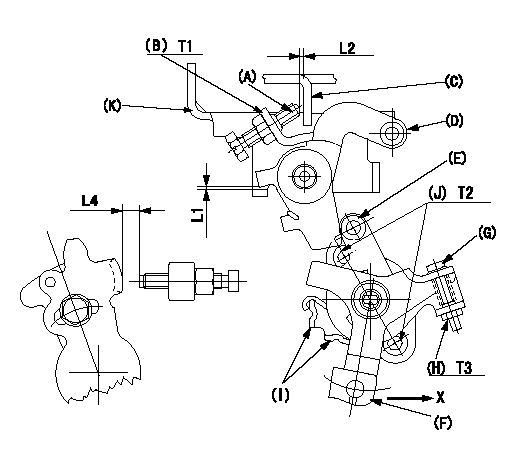

0000002101 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever (C) in the idle position.

(2)Insert a block gauge (thickness gauge) L1 between the intermediate lever (D) and the bracket (K). Adjust screw (A) so that the distance between screw A and the control lever to L2 and fix using the nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever F in the direction X until it contacts the stopper I and tighten the socket head bolt J when the timer stroke is L3.

3. Screw (G) adjustment

(1)Adjust using the screw G so that the roller E contacts the intermediate lever D, then fix using the nut H.

(2)Pull the CSD lever F in the direction X until it contacts the stopper I and confirm that the control lever shim thickness (lever position) is L4.

Note: Use screw (A) to fine-adjust the lever position. [Maintain a gap L2 between the screw (A) and the control lever (C).]

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=3.8+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1+-0.1mm L2=1~2mm L4=3.8+-0.5mm

----------

L1=1+-0.1mm L2=1~2mm L3=0.82+-0.2mm L4=3.8+-0.5mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=5~7N-m(0.5~0.7kgf-m) T3=2~3N-m(0.2~0.3kgf-m) L1=1+-0.1mm L2=1~2mm L4=3.8+-0.5mm