Rating:

Information injection-pump assembly

BOSCH

9 460 614 249

9460614249

ZEXEL

104700-9130

1047009130

Cross reference number

BOSCH

9 460 614 249

9460614249

ZEXEL

104700-9130

1047009130

Zexel num

Bosch num

Firm num

Name

104700-9130

9 460 614 249

INJECTION-PUMP ASSEMBLY

4D56TCI

4D56TCI

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Governor adjustment

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

598.5

569

628

Pump chamber pressure

kgf/cm2

6.1

5.8

6.4

Basic

*

Governor adjustment_02

Pump speed

r/min

100

100

100

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

294

294

Pump chamber pressure

kgf/cm2

3

3

Governor adjustment_03

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

598.5

559

638

Pump chamber pressure

kgf/cm2

6.1

5.7

6.5

Governor adjustment_04

Pump speed

r/min

2000

2000

2000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Pump chamber pressure

kPa

736

687

785

Pump chamber pressure

kgf/cm2

7.5

7

8

Boost compensator adjustment

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

7.7

7.5

7.9

Basic

*

Boost compensator adjustment_02

Pump speed

r/min

100

100

100

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

1.8

0.3

3.3

Boost compensator adjustment_03

Pump speed

r/min

350

350

350

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

5.2

3.1

7.3

Boost compensator adjustment_04

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

7.7

7.4

8

Boost compensator adjustment_05

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

70

70

70

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

4

1.9

6.1

Boost compensator adjustment_06

Pump speed

r/min

2000

2000

2000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

9.75

9.3

10.2

Boost compensator adjustment_07

Pump speed

r/min

2000

2000

2000

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Timer stroke

mm

0

0

0

Timer adjustment

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Vtps

V

0.51

0.382

0.638

Basic

*

Timer adjustment_02

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

0

0

0

U alpha soll

V

2.7

2.7

2.7

Vtps

V

0.51

0.382

0.638

Timer adjustment_03

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Vtps

V

1.925

1.702

2.148

Speed control lever angle

Pump speed

r/min

1000

1000

1000

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Overflow quantity

cm3/min

550

420

680

0000000901

Pump speed

r/min

1250

1250

1250

U alpha soll + dU alpha soll

V

2.9

2.9

2.9

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

72.1

71.6

72.6

Difference in delivery

mm3/st.

3.5

Basic

*

_02

Pump speed

r/min

375

375

375

U alpha soll + dU alpha soll

V

1.9

1.9

1.9

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

13.3

10.3

16.3

Difference in delivery

mm3/st.

2.5

Basic

*

Remarks

Confirmation of difference in delivery

Confirmation of difference in delivery

_03

Pump speed

r/min

2650

2650

2650

U alpha soll + dU alpha soll

V

1.8

1.8

1.8

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

16.9

14.4

19.4

Difference in delivery

mm3/st.

5.5

Basic

*

Remarks

Confirmation of difference in delivery

Confirmation of difference in delivery

_04

Pump speed

r/min

100

100

100

U alpha soll + dU alpha soll

V

2.9

2.9

2.9

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

51.9

41.9

61.9

_05

Pump speed

r/min

375

375

375

U alpha soll + dU alpha soll

V

1.9

1.9

1.9

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

13.3

10.3

16.3

_06

Pump speed

r/min

500

500

500

U alpha soll + dU alpha soll

V

2.57

2.57

2.57

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

50.8

48.3

53.3

_07

Pump speed

r/min

750

750

750

U alpha soll + dU alpha soll

V

2.79

2.79

2.79

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

66.6

64.1

69.1

_08

Pump speed

r/min

1000

1000

1000

U alpha soll + dU alpha soll

V

2.88

2.88

2.88

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

71.7

69.2

74.2

_09

Pump speed

r/min

1250

1250

1250

U alpha soll + dU alpha soll

V

2.9

2.9

2.9

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

72.1

71.1

73.1

_10

Pump speed

r/min

1500

1500

1500

U alpha soll + dU alpha soll

V

2.86

2.86

2.86

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

71.2

68.7

73.7

_11

Pump speed

r/min

1750

1750

1750

U alpha soll + dU alpha soll

V

2.88

2.88

2.88

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

69.6

67.1

72.1

_12

Pump speed

r/min

2000

2000

2000

U alpha soll + dU alpha soll

V

2.84

2.84

2.84

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

67.6

65.1

70.1

_13

Pump speed

r/min

2650

2650

2650

U alpha soll + dU alpha soll

V

1.8

1.8

1.8

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

16.9

14.4

19.4

_14

Pump speed

r/min

2650

2650

2650

U alpha soll + dU alpha soll

V

1

1

1

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

mm3/st.

3

Stop lever angle

Pump speed

r/min

2000

2000

2000

U alpha soll + dU alpha soll

V

2.84

2.84

2.84

TCV duty (%) F TCV 60Hz

%

100

100

100

Average injection quantity

cm3/min

0

0

0

0000001101

Pump speed

r/min

200

200

200

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.7

2.7

2.7

Speed output

N=Measure the actual speed. r/min N+-8

N=Measure the actual speed. r/min N+-8

0000001201

Pump speed

r/min

1250

1250

1250

TCV duty (%) F TCV 60Hz

%

100

100

100

U alpha soll

V

2.9

2.9

2.9

Temperature output

Measure T = actual output temperature degC T+-5

Measure T = actual output temperature degC T+-5

0000001301

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.9

5.8

6

Pre-stroke

mm

0.1

0.08

0.12

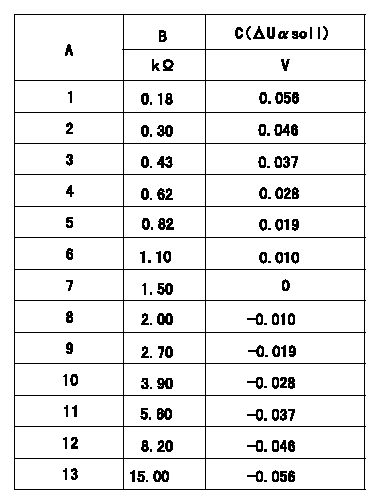

Test data Ex:

Injection timing adjustment Comp. resistor/voltage

Compensation resistance/compensation voltage comparison

A = Compensation resistor number

B= Compensation resistance

C = Compensation voltage delta U alpha soll

----------

----------

----------

----------

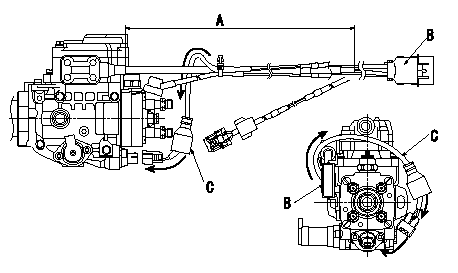

0000001601 HARNESS & CONNECTOR

T.C.V. connector assembly specification

(1)Ensure the GE cable is not twisted at section A.

(2)Refer to diagram for direction of connector B.

(3)Route the TCV harnes C in the direction indicated by the arrows in the figure and install the connector.

----------

----------

----------

----------

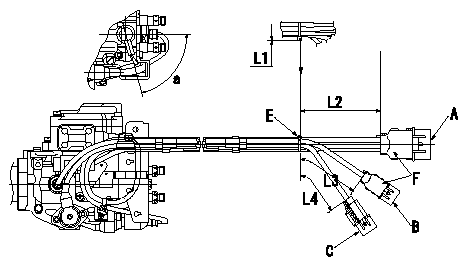

0000001701 HARNESS & CONNECTOR

Harness position specification

(1)Install the rear cover of the GE side connector and the NP and FCV connector.

(2)Fix the harness using clips to the dimensions shown in the figure.

(3)Cut A to L1 or less.

(4)After completing the procedures, the lead wires must not be exposed or visible at the connector's rear cover.

B = GE, TCV, Q adjustment

C=NP,FCV

D=TPS

E = binder

F = connector's rear cover

----------

----------

a=(75deg) L1=Max.2mm L2=85+11-9mm L3=65+11-9mm L4=55+11-9mm

----------

----------

a=(75deg) L1=Max.2mm L2=85+11-9mm L3=65+11-9mm L4=55+11-9mm

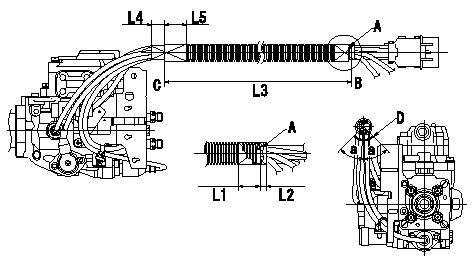

0000001801 HARNESS & CONNECTOR

Corrugated tube assembly specification

(1)Align the end of the corrugated tube with clip A and fix it using black vinyl tape (L1, L2).

(2)Confirm that the dimension to the end of the corrugated tube C is L3, and fix it using black vinyl tape (L4, L5).

(3)Refer to the illustration for the position of the corrugated tube slit.

(4)After completing all of the procedures, ensure no lead wires are exposed after routing the harness.

A = binder

B = outside edge of binder

C = end of corrugated tube

D = position of corrugated tube's slit

----------

----------

L1=Max.25mm L2=Max.10mm L3=325+-10mm L4=(20mm) L5=(30mm) a=45deg

----------

----------

L1=Max.25mm L2=Max.10mm L3=325+-10mm L4=(20mm) L5=(30mm) a=45deg

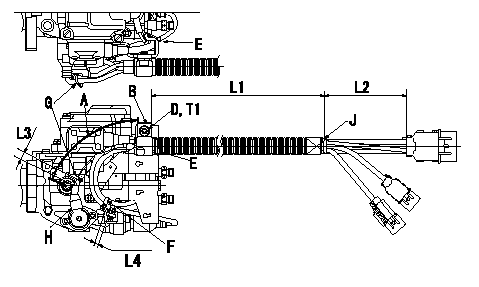

0000001901 HARNESS & CONNECTOR

Harness fixing specification

(1)At the clip position J at dimension L2 from the rear end of the connector, and the dimension L1 from the metal end of the clip B, fix using the socket head bolt and the spring washer.

(2)Adjust the length of dimension L1 within the tolerance so that the TPS and Np harness at A is not excessively loose, then fix using the clip.

(3)Clip the GE cable and the FCV harness using clip E, the GE cable and the FCV-TCV harness using clip F, and the TPS-NP harness using clip G.

(4)Attach the binder G after ensuring that the TPS cover H is not loose.

B = clip

D = socket head bolt

E = binder

F = binder

G=Binder

H = TPS cover

J = clip position

----------

----------

L1=300+-10mm L2=(85mm) L3=5~15mm L4=5~15mm T1=9.8~13.7N-m(1.0~1.4kgf-m)

----------

----------

L1=300+-10mm L2=(85mm) L3=5~15mm L4=5~15mm T1=9.8~13.7N-m(1.0~1.4kgf-m)

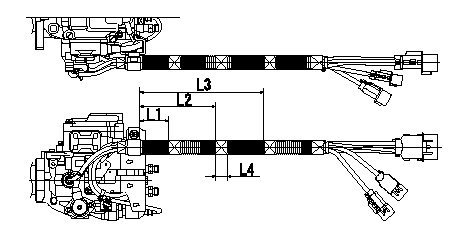

0000002001 HARNESS & CONNECTOR

Vinyl tape assembly specification

Wrap with black vinyl tape (at 3 positions) from the end of the clip's metal portion at the positions shown in the figure (dimensions indicated).

----------

----------

L1=55+-10mm L2=125+-10mm L3=195+-10mm L4=(20mm)

----------

----------

L1=55+-10mm L2=125+-10mm L3=195+-10mm L4=(20mm)

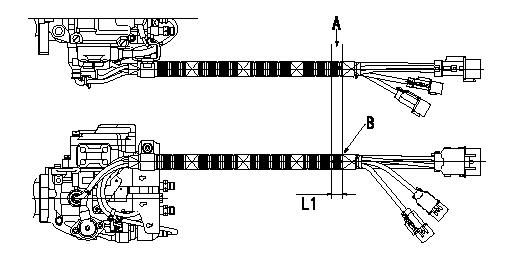

0000002101 HARNESS & CONNECTOR

Marking application specification

(1)Ensure the corrugated tube is not twisted and then mark the position A shown in the figure.

(2)2) Use indelible paint for steel.

(3)3) Mark at the two locations indicated in the figure ( viewed from the side of the pump and the top of the pump). The markings must be the dimensions shown and approx. 5 mm wide.

A = white marking

B = End of tape binding

----------

----------

L1=20+-5mm

----------

----------

L1=20+-5mm

Have questions with 104700-9130?

Group cross 104700-9130 ZEXEL

Hyundai

Hyundai

Hyundai

Hyundai

104700-9130

9 460 614 249

INJECTION-PUMP ASSEMBLY

4D56TCI

4D56TCI