Rating:

Information injection-pump assembly

BOSCH

F 01G 09U 04V

f01g09u04v

ZEXEL

101607-1041

1016071041

Cross reference number

BOSCH

F 01G 09U 04V

f01g09u04v

ZEXEL

101607-1041

1016071041

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

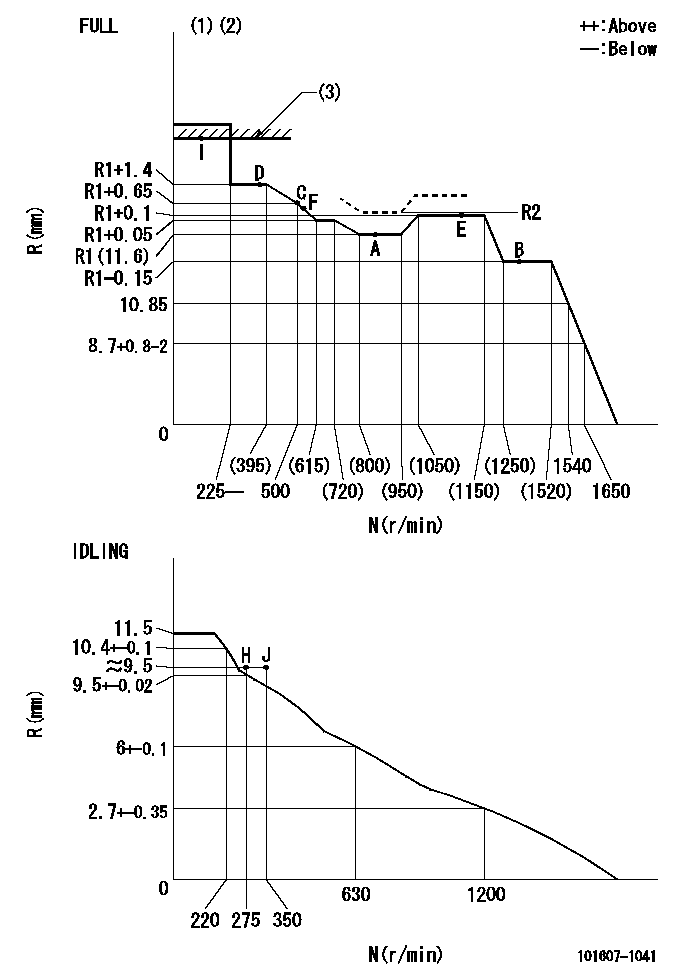

Injection quantity adjustment

Adjusting point

-

Rack position

11.6

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

72.5

70.3

74.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

8.3

7.1

9.5

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.6)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

72.5

71.5

73.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.15

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

79.5

75.5

83.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.65

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

71.5

67.5

75.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

14.8+-0.

2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

100

140

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_03

Pump speed

r/min

1380

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT: RAL

----------

T1=F14 RAL=14.8+-0.2mm

----------

----------

T1=F14 RAL=14.8+-0.2mm

----------

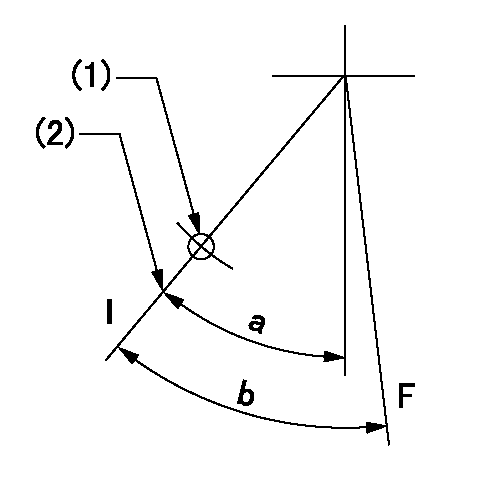

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=33deg+-5deg b=(40deg)+-3deg

----------

aa=35mm

----------

a=33deg+-5deg b=(40deg)+-3deg

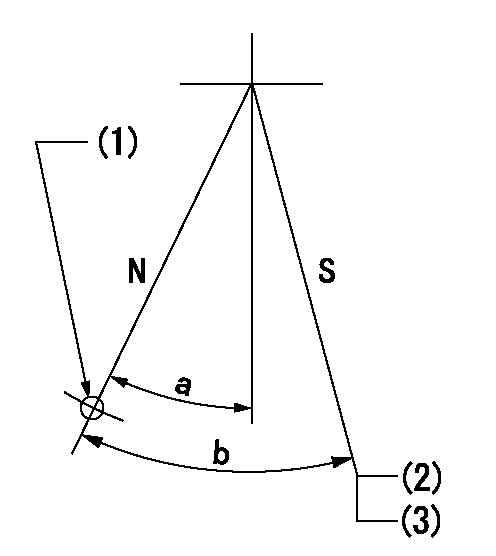

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt at speed = bb and rack position = cc (non-injection rack position). Confirm non-injection.

(3)After setting the stopper bolt, confirm non-injection at speed dd. Rack position = ee (non-injection rack position)

----------

aa=50mm bb=1400r/min cc=6.9-0.5mm dd=275r/min ee=(8.9)-0.5mm

----------

a=25deg+-5deg b=25deg+-5deg

----------

aa=50mm bb=1400r/min cc=6.9-0.5mm dd=275r/min ee=(8.9)-0.5mm

----------

a=25deg+-5deg b=25deg+-5deg

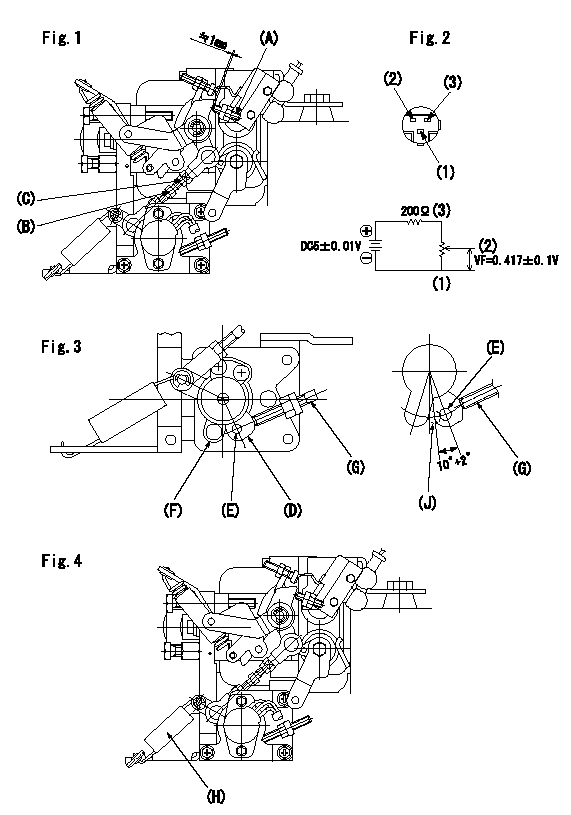

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

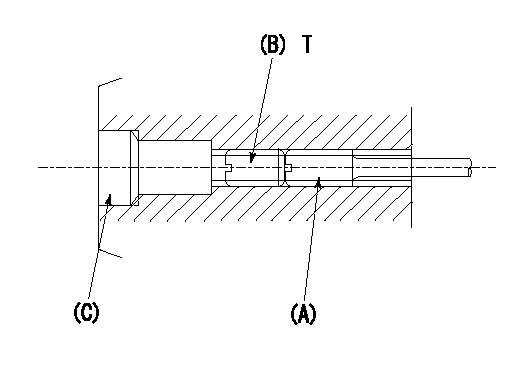

0000001601 TAMPER PROOF

1. Method for setting tamperproof proofing

(1)After governor adjustment (torque cam phase adjustment), move the load lever to increase the full rack position to Ra.

(2)At speed N1 screw in screw (A) to obtain the rack position (actual measurement: Rb) for injection quantity Q1.

(3)Temporarily caulk using the tip of a screwdriver

(4)Confirm that the rack at that time is at Rc.

(5)Lock using setscrew (B). (Tightening torque = T)

(6)Next, coat (C) with adhesive and then pressfit.

(7)Then, readjust the full rack position using the load lever.

----------

N1=850r/min Q1=78.3+-1mm3/st Ra=(0.4)mm Rb=R2mm Rc=R2mm

----------

T=3.4~4.9N-m(0.35~0.5Kgf-m)

----------

N1=850r/min Q1=78.3+-1mm3/st Ra=(0.4)mm Rb=R2mm Rc=R2mm

----------

T=3.4~4.9N-m(0.35~0.5Kgf-m)

0000001701 LEVER

(A) Accelerator lever stopper bolt

(B) Link

(c) Nut

(D) Lever

(E) Pin

(f) lever

(G) Stopper bolt

(H) Return spring

(J) Pin (E) contacts lever.

(K) Load sensor terminal

(1)Black

(2)Blue-yellow

(3)Blue-red

Setting the accelerator lever angle, load sensor adjustment

1. Accelerator lever setting method

(1)Position the speed lever against the idle stopper bolt and fix.

(2)Screw in the accelerator lever stopper bolt (A) and back off the stopper bolt (A) from the position where the accelerator lever pin contacts the speed lever and set. (Gap: approx. 1 mm)

Tightening torque: 4.9~7 N.m {0.5~0.7 kgf.m}

2. Load sensor adjustment (See fig 1)

(1)Load sensor output measuring circuit

Apply DC5+-0.01V to the load sensor terminals and measure the output voltage.

(2)Load sensor output adjustment procedure

Hold the speed lever against the full side stopper bolt and fix. Adjust the load sensor output voltage to VF = 0.417+-0.1 V using the link (B) and then fix temporarily using nut (C).

Turn the speed lever from the idle side to the full side and confirm that output voltage VF = 0.417+-0.1 V is obtained. Confirm several times and then fix using nut (C).

Tightening torque: 3.4~4.9 N.m {0.35~0.5 kgf.m}

3. Setting the step motor's idle side stopper bolt

After adjustment in previous 1 and 2, position speed lever against idle stopper bolt and fix. Then, screw in stopper bolt G until step motor lever D's pin E contacts lever F. Back off 10+2 deg (approx. 3.5 mm) from this position and fix G. (See fig. 3)

4. Speed lever return confirmation

(1)Remove return spring (H) and confirm that the speed lever is returned to the idle position by the torsion spring.

(2)Reinstall the return spring (H) in its original position.

----------

----------

----------

----------

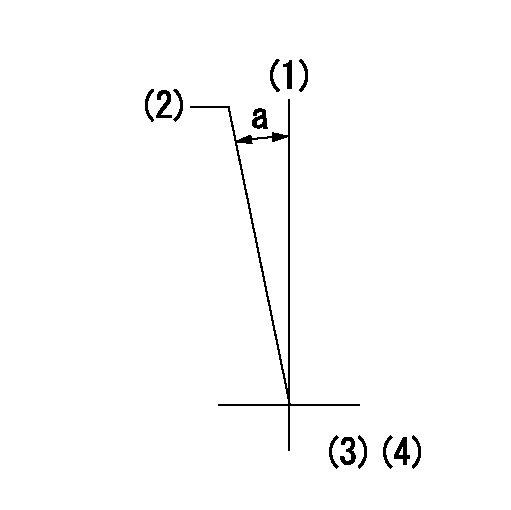

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(1deg)

----------

aa=11deg

----------

a=(1deg)