Information injection-pump assembly

BOSCH

9 400 610 603

9400610603

ZEXEL

101602-7910

1016027910

ISUZU

1156031380

1156031380

Rating:

Service parts 101602-7910 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-331-0

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101602-7910

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-1691

as _

Cross reference number

BOSCH

9 400 610 603

9400610603

ZEXEL

101602-7910

1016027910

ISUZU

1156031380

1156031380

Zexel num

Bosch num

Firm num

Name

101602-7910

9 400 610 603

1156031380 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1-T K 14BF INJECTION PUMP ASSY PE6AD PE

6BG1-T K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-4920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1025

1025

1025

Average injection quantity

mm3/st.

80.5

79

82

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.8+-0.5

Pump speed

r/min

465

465

465

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

86

81

91

Fixing the lever

*

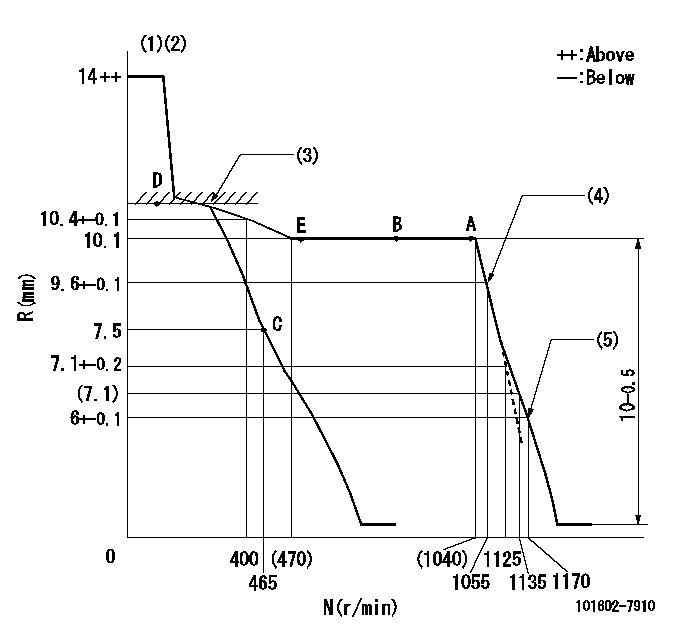

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Main spring setting

(5)Set idle sub-spring

----------

K=12

----------

----------

K=12

----------

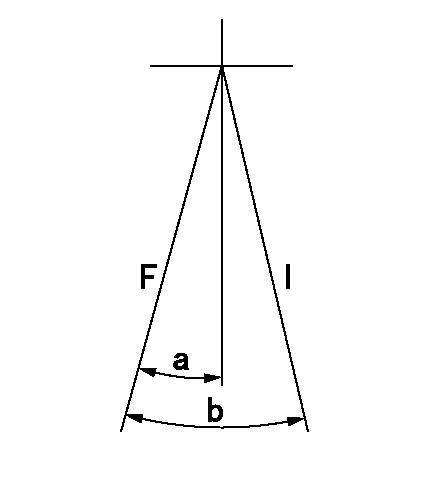

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=6deg+-5deg b=17deg+-5deg

----------

----------

a=6deg+-5deg b=17deg+-5deg

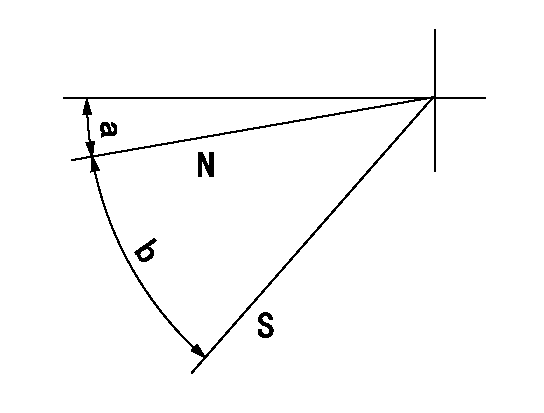

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=2.5deg+-5deg b=46deg+-5deg

----------

----------

a=2.5deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark 'CC' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(100deg)

----------

aa=12deg

----------

a=(100deg)

Information:

Fuel Injection Nozzles

Disassembly of Fuel Injection Nozzles

Inspection of Fuel Injection Nozzles

Check each fuel injection nozzle for the following, and if defects are found, repair or replace the fuel injection nozzle.(1) Inspection of injection start pressure(a) Install each fuel injection nozzle on the nozzle tester, and move the handle up and down to release air.(b) Operate the handle of the tester at a rate of about 1 stroke per second, and read the indication on the pressure gage. The indication rises slowly, and the indicator oscillates during spraying. To obtain the injection start pressure value, read the indication when the indicator starts to oscillate.

Inspection of fuel injection nozzle valve opening(c) If the injection start pressure deviates significantly from the standard value, disassemble the fuel injection nozzle, and make an adjustment by changing the washer thickness. 0.1 mm [0.0039 in.] thickness of shims will change the injection pressure 0.98 Mpa (10 kgf/cm2 [142 psi]. The shims are available in 10 different thickness from 1.25 to 1.70 mm [0.0492 to 0.0669 in.] increment of 0.05 mm [0.0020 in.]

Never tap the tip of the nozzle tip when removing the nozzle tip.

Replacement of fuel injection nozzle tip(2) Inspection of fuel injection nozzle spray pattern(a) When inspecting each fuel injection nozzle with the nozzle tester, also check the nozzle for clogs, spray pattern and leakage.(b) Make sure that the fuel is sprayed straight from the nozzle when the handle of the tester is operated at a rate of about 1 stroke per second.

Inspection of spray pattern of fuel injection nozzle(3) Cleaning and replacement of faulty nozzles(a) Loosen the nozzle retaining nut, remove the nozzle tip, and clean the needle valve and body.

Never tap the tip of the nozzle tip when removing the nozzle tip.

(b) Use a fresh cleaning solution to clean the needle valve and body. After cleaning, assemble the needle valve and body in clean diesel fuel. The needle valve and body are precision finished. Handle them carefully, and do not change the combination of parts.

Cleaning of fuel injection nozzle tip(c) Tighten the nozzle retaining nut on the nozzle tip to the specified torque.(d) If the spray pattern is still not acceptable after adjustment and cleaning, replace the nozzle tip. (a) Never touch the sliding surface of the needle valve.(b) When installing a new nozzle tip, remove the seal film (synthetic resin film), and slide needle valve in the nozzle in a fresh cleaning solution to remove anti-rust oil coating thoroughly from the new nozzleReassembly of Fuel Injection Nozzles

Disassembly of Fuel Injection Nozzles

Inspection of Fuel Injection Nozzles

Check each fuel injection nozzle for the following, and if defects are found, repair or replace the fuel injection nozzle.(1) Inspection of injection start pressure(a) Install each fuel injection nozzle on the nozzle tester, and move the handle up and down to release air.(b) Operate the handle of the tester at a rate of about 1 stroke per second, and read the indication on the pressure gage. The indication rises slowly, and the indicator oscillates during spraying. To obtain the injection start pressure value, read the indication when the indicator starts to oscillate.

Inspection of fuel injection nozzle valve opening(c) If the injection start pressure deviates significantly from the standard value, disassemble the fuel injection nozzle, and make an adjustment by changing the washer thickness. 0.1 mm [0.0039 in.] thickness of shims will change the injection pressure 0.98 Mpa (10 kgf/cm2 [142 psi]. The shims are available in 10 different thickness from 1.25 to 1.70 mm [0.0492 to 0.0669 in.] increment of 0.05 mm [0.0020 in.]

Never tap the tip of the nozzle tip when removing the nozzle tip.

Replacement of fuel injection nozzle tip(2) Inspection of fuel injection nozzle spray pattern(a) When inspecting each fuel injection nozzle with the nozzle tester, also check the nozzle for clogs, spray pattern and leakage.(b) Make sure that the fuel is sprayed straight from the nozzle when the handle of the tester is operated at a rate of about 1 stroke per second.

Inspection of spray pattern of fuel injection nozzle(3) Cleaning and replacement of faulty nozzles(a) Loosen the nozzle retaining nut, remove the nozzle tip, and clean the needle valve and body.

Never tap the tip of the nozzle tip when removing the nozzle tip.

(b) Use a fresh cleaning solution to clean the needle valve and body. After cleaning, assemble the needle valve and body in clean diesel fuel. The needle valve and body are precision finished. Handle them carefully, and do not change the combination of parts.

Cleaning of fuel injection nozzle tip(c) Tighten the nozzle retaining nut on the nozzle tip to the specified torque.(d) If the spray pattern is still not acceptable after adjustment and cleaning, replace the nozzle tip. (a) Never touch the sliding surface of the needle valve.(b) When installing a new nozzle tip, remove the seal film (synthetic resin film), and slide needle valve in the nozzle in a fresh cleaning solution to remove anti-rust oil coating thoroughly from the new nozzleReassembly of Fuel Injection Nozzles

Have questions with 101602-7910?

Group cross 101602-7910 ZEXEL

Isuzu

101602-7910

9 400 610 603

1156031380

INJECTION-PUMP ASSEMBLY

6BG1-T

6BG1-T