Information injection-pump assembly

BOSCH

F 019 Z20 439

f019z20439

ZEXEL

101431-0640

1014310640

ISUZU

5156010332

5156010332

Rating:

Service parts 101431-0640 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

5-15300-039-1

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z20 439

f019z20439

ZEXEL

101431-0640

1014310640

ISUZU

5156010332

5156010332

Zexel num

Bosch num

Firm num

Name

101431-0640

F 019 Z20 439

5156010332 ISUZU

INJECTION-PUMP ASSEMBLY

C240 * K 14BC PE4A,5A, PE

C240 * K 14BC PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-3-4-2

Pre-stroke

mm

2.25

2.2

2.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.4

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

33

31.4

34.6

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

11.8

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

36.5

35.5

37.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

8.8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7

5.9

8.1

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

1

0.5

1.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.2

2.7

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

4.5

3.9

4.9

Timer adjustment_05

Pump speed

r/min

1750

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

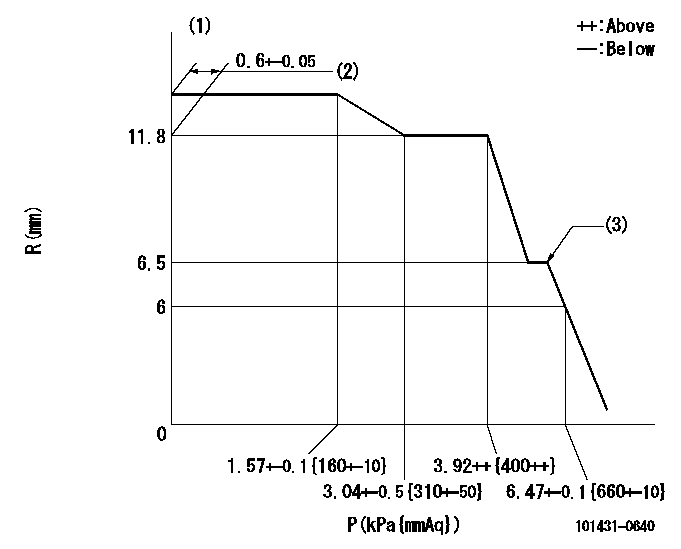

Governor adjustment

R:Rack position (mm)

P:Negative pressure

(1)Pneumatic governor

(2)Torque control stroke

(3)Beginning of idle sub spring operation: L1

----------

L1=6.5-0.5mm

----------

----------

L1=6.5-0.5mm

----------

Timing setting

(1)Pump vertical direction

(2)Gear mark Z for the No. 4 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Information:

1. Remove wiring harnesses from bracket (1). 2. Disconnect the wires at connections (5) Remove line (4). Remove five bolts (2), bracket (1) cover (3) and the gasket. 3. Remove two bolts (6) and clamps. Remove rack solenoid. (7) 4. Disconnect wires at connections (8). Remove two bolts (10) and bracket assembly (9). Loosen the locknut and remove rack position sensor (11). Be careful not to lose the spring that is around the sensor. To remove the transducer module at this time use the following procedure.a. disconnect wires at connector (8)b. remove the connector from the wiresc. remove four bolts that fasten transducer module (22) to housing (15)d. feed the wires through housing (18) while removing the transducer module. 5. Remove three bolts (12) from inside housing (14). Remove two bolts (13) and remove housing (14). 6. Loosen locknut (15) and remove engine speed sensor (16). 7. Remove seven bolts (17) and remove the transducer module and housing (18). 8. Remove three bolts (19) and cover (20). 9. Remove two bolts (21). Remove transducer module (22) and gasket. 10. Remove lockring (27), seat (25), spring (24), sleeve (23) and lockring (26). 11. Remove three bolts (28) and remove cylinder (29). 12. Remove sleeve (30), piston (31) and valve (32). Remove O-ring seal (33) from sleeve (30). 13. Remove bolts (34) and remove retainer (35). Remove two races and one bearing (not shown).Assemble Rack Actuator Package

1. Lubricate bearing (37) with engine oil. Install race (36), bearing (37), race (36) and retainer (35) on the fuel injection pump camshaft. 2. Lubricate O-ring seal (33) with engine oil and install on sleeve (30). Install sleeve (32) and piston (31) into sleeve (33). 3. Install sleeve (30) into cylinder (29).4. Install lockring (26), sleeve (23), spring (24), seat (25) and lockring (27) on valve (32). 5. Put cylinder assembly (29) in position on the fuel injection pump housing with piston (31) engaged over fuel injection pump rack (38). Be sure that rack (38) is properly engaged with piston (31). 6. Fasten cylinder (29) to the fuel injection pump housing with three bolts (28). The rack and servo valve (32) must move freely after bolts (28) are tight. 7. Install gasket (39) and transducer module (22) on housing (18). 8. Place wire harness (40) in the slot of the housing. 9. Install cover (20) and bolts (19). 10. Install the gasket and housing (18) on the fuel injection pump housing with seven bolts (17). 11. Install engine speed sensor (16) until it contacts retainer (35). Back the engine speed sensor out (counterclockwise) 180°. This procedure will provide a clearance of .76 mm (.030 in). Tighten locknut (15) to a torque of 13 2 N m (10 1 lb.ft.). 12. Install gasket and housing (14).13. Install the rack position sensor damping seal in housing (14). Install the spring and rack position sensor (11) in housing (14). 14. Connect the rack position sensor wiring connector to the transducer module wiring connector (P8 to

1. Lubricate bearing (37) with engine oil. Install race (36), bearing (37), race (36) and retainer (35) on the fuel injection pump camshaft. 2. Lubricate O-ring seal (33) with engine oil and install on sleeve (30). Install sleeve (32) and piston (31) into sleeve (33). 3. Install sleeve (30) into cylinder (29).4. Install lockring (26), sleeve (23), spring (24), seat (25) and lockring (27) on valve (32). 5. Put cylinder assembly (29) in position on the fuel injection pump housing with piston (31) engaged over fuel injection pump rack (38). Be sure that rack (38) is properly engaged with piston (31). 6. Fasten cylinder (29) to the fuel injection pump housing with three bolts (28). The rack and servo valve (32) must move freely after bolts (28) are tight. 7. Install gasket (39) and transducer module (22) on housing (18). 8. Place wire harness (40) in the slot of the housing. 9. Install cover (20) and bolts (19). 10. Install the gasket and housing (18) on the fuel injection pump housing with seven bolts (17). 11. Install engine speed sensor (16) until it contacts retainer (35). Back the engine speed sensor out (counterclockwise) 180°. This procedure will provide a clearance of .76 mm (.030 in). Tighten locknut (15) to a torque of 13 2 N m (10 1 lb.ft.). 12. Install gasket and housing (14).13. Install the rack position sensor damping seal in housing (14). Install the spring and rack position sensor (11) in housing (14). 14. Connect the rack position sensor wiring connector to the transducer module wiring connector (P8 to

Have questions with 101431-0640?

Group cross 101431-0640 ZEXEL

Isuzu

Isuzu

101431-0640

F 019 Z20 439

5156010332

INJECTION-PUMP ASSEMBLY

C240

C240