Rating:

Information injection-pump assembly

BOSCH

9 400 613 253

9400613253

ZEXEL

101405-3310

1014053310

KOMATSU

4063772

4063772

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fastenere Nylon Insert Hex Lock Nuts - #10-32 (1000-Pack) Solid Brass Alloy Steel Grade 360, Plain Finish, Corrosion-Resistant, Durable Multi-Use Hardware Nuts - Secure Fastening w/Hex Socket Drive

Fastenere PRECISION ENGINEERING: Engineered with precision, this #10 lock nut has 32 threads per inch. These bright yellow, brass finish lock nuts ensure tight, stable assemblies, vital for both industrial applications and home DIY projects, securing everything from machinery to hardware nuts with impeccable precision. || DURABLE MATERIAL: Made of Grade 360 Brass, known for its strength and resistance to corrosion with properties closely resembling that of steel and offering the highest machinability of all copper alloys, our hex lock nut resists corrosion and oxidation effectively. This resilience makes them ideal for any setting, enhancing longevity and reliability across a spectrum of environments. || SECURE FASTENING: Nylon insert lock nuts provide a locking mechanism that resists vibrations and torque that could cause loosening. This causes the nylon lock nut to grip better against the threads and reduces the chances of the nut loosening due to the vibration of the screw. || EASY INSTALLATION: Our nuts are designed for swift installation using an external hex drive, making them user-friendly for both novices and professionals. They work efficiently with a variety of tools and accessories, including stainless steel trim, hardware assortment kits, and even nylon washers, ensuring quick and effective assembly. || VALUE PACK: Our 1000-pack offers substantial value, catering to extensive needs from small bolts and nuts for detailed tasks to bulk requirements in industrial settings. This pack not only supports large-scale operations but also serves as an essential component in stainless steel bolts and nuts kits, providing exceptional quality and cost-effectiveness.

Fastenere PRECISION ENGINEERING: Engineered with precision, this #10 lock nut has 32 threads per inch. These bright yellow, brass finish lock nuts ensure tight, stable assemblies, vital for both industrial applications and home DIY projects, securing everything from machinery to hardware nuts with impeccable precision. || DURABLE MATERIAL: Made of Grade 360 Brass, known for its strength and resistance to corrosion with properties closely resembling that of steel and offering the highest machinability of all copper alloys, our hex lock nut resists corrosion and oxidation effectively. This resilience makes them ideal for any setting, enhancing longevity and reliability across a spectrum of environments. || SECURE FASTENING: Nylon insert lock nuts provide a locking mechanism that resists vibrations and torque that could cause loosening. This causes the nylon lock nut to grip better against the threads and reduces the chances of the nut loosening due to the vibration of the screw. || EASY INSTALLATION: Our nuts are designed for swift installation using an external hex drive, making them user-friendly for both novices and professionals. They work efficiently with a variety of tools and accessories, including stainless steel trim, hardware assortment kits, and even nylon washers, ensuring quick and effective assembly. || VALUE PACK: Our 1000-pack offers substantial value, catering to extensive needs from small bolts and nuts for detailed tasks to bulk requirements in industrial settings. This pack not only supports large-scale operations but also serves as an essential component in stainless steel bolts and nuts kits, providing exceptional quality and cost-effectiveness.

Service parts 101405-3310 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

4063212

12.

Open Pre:MPa(Kqf/cm2)

22.0{224}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 253

9400613253

ZEXEL

101405-3310

1014053310

KOMATSU

4063772

4063772

Zexel num

Bosch num

Firm num

Name

101405-3310

9 400 613 253

4063772 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

SAA4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

101405-3310

9 400 613 253

6737711230 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

SAA4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.7

2.65

2.75

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

93.5

92.5

94.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

45.3

45.3

Boost pressure

mmHg

340

340

Hydraulic cylinder ON

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.4+-0.5

Pump speed

r/min

485

485

485

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder ON

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

9.4++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

60

70

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-1

Boost pressure

kPa

10.7

8

13.4

Boost pressure

mmHg

80

60

100

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1-0.4

Boost pressure

kPa

20

18.7

21.3

Boost pressure

mmHg

150

140

160

Boost compensator adjustment_03

Pump speed

r/min

650

650

650

Rack position

R1(9.2)

Boost pressure

kPa

32

32

32

Boost pressure

mmHg

240

240

240

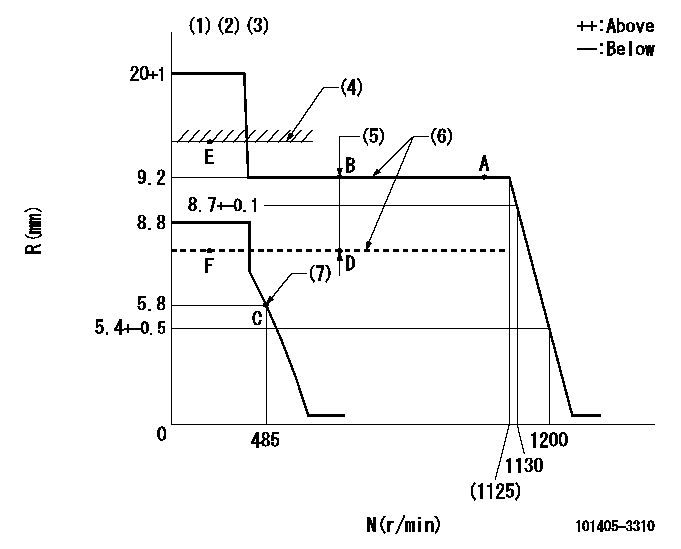

Test data Ex:

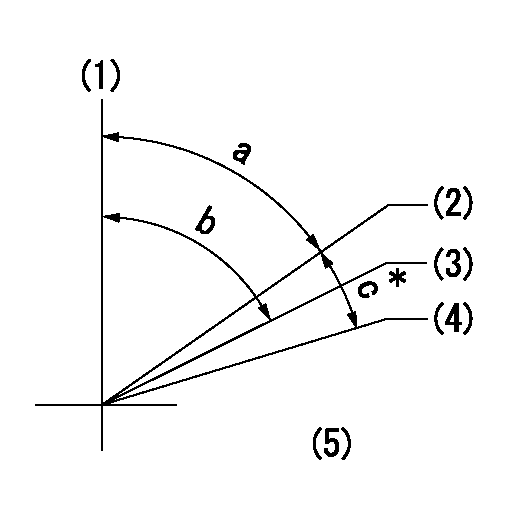

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver without the torque control spring operating.

(4)RACK LIMIT (When hydraulic cylinder is OFF)

(5)Boost compensator stroke: BCL

(6)When hydraulic cylinder ON: P1

(7)Set idle sub-spring

----------

K=14 BCL=1+-0.1mm P1=(127+-10kPa{1.3+-0.1kgf/cm2})

----------

----------

K=14 BCL=1+-0.1mm P1=(127+-10kPa{1.3+-0.1kgf/cm2})

----------

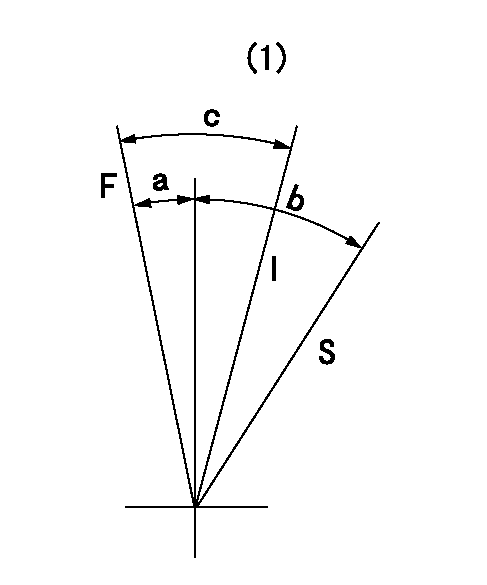

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Use the center hole at R = aa

----------

aa=80mm

----------

a=16deg+-5deg b=32deg+-3deg c=35deg+-5deg

----------

aa=80mm

----------

a=16deg+-5deg b=32deg+-3deg c=35deg+-5deg

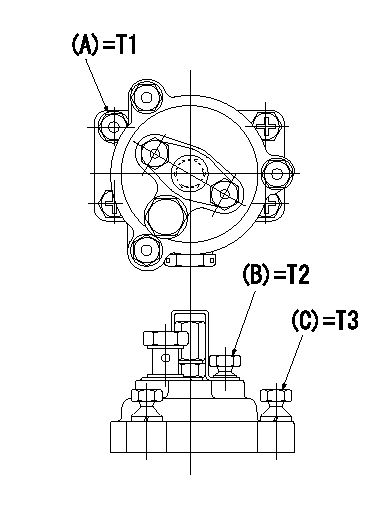

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(1)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

(3)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T3)

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

0000001601 I/P WITH LOAD PLUNGER ADJ

Adjusting procedure for load plunger equipped pump with RSV (cam lock) governor (see service information S.I. 434 for details).

At cam lift h+-0.01, set the camshaft c deg from the * mark in accordance with the timing adjustment procedure.

2. Align the flyweight's timing tooth position and the lock pin groove and then fully tighten the flyweight to the camshaft. Then, remove the lock pin.

3. Adjust the maximum variation between cylinders and injection quantity.

4. Adjust using the pre-stroke adjusting shim so that the pre-stroke value is the value for 4/4 load (standard point A).

5. After adjusting the pre-stroke, reconfirm that the injection quantity and the maximum variation between cylinders are as specified.

6. At delivery, again fix the flyweight using the lock pin.

----------

h=2.7+-0.01mm c=5deg45min+-30min

----------

----------

h=2.7+-0.01mm c=5deg45min+-30min

----------

Timing setting

(1)Pump vertical direction

(2)Key groove position for No. 1 cylinder's cam lift h = cc (at BTDC aa).

(3)Key groove position for No. 1 cylinder's beginning of injection (at point A after injection quantity adjustment).

(4)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(5)B.T.D.C.: aa

----------

aa=11.5deg bb=0deg cc=2.7+-0.01mm

----------

a=55deg48min+-3deg b=55deg48min+-3deg13min48sec c=5deg45min+-30min

----------

aa=11.5deg bb=0deg cc=2.7+-0.01mm

----------

a=55deg48min+-3deg b=55deg48min+-3deg13min48sec c=5deg45min+-30min

Have questions with 101405-3310?

Group cross 101405-3310 ZEXEL

Komatsu

101405-3310

9 400 613 253

4063772

INJECTION-PUMP ASSEMBLY

SAA4D102E

SAA4D102E

101405-3310

9 400 613 253

6737711230

INJECTION-PUMP ASSEMBLY

SAA4D102E

SAA4D102E