Rating:

Information injection-pump assembly

ZEXEL

104740-2393

1047402393

Cross reference number

ZEXEL

104740-2393

1047402393

Zexel num

Bosch num

Firm num

Name

104740-2393

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

Excluding timer, pump chamber pressure ON

Excluding timer, pump chamber pressure ON

Injection timing adjustment

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

36.2

37

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

11.5

16.5

Injection timing adjustment_03

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

36.1

32.6

39.6

Injection timing adjustment_04

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

37.3

34.8

39.8

Injection timing adjustment_05

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

36.6

35.7

37.5

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32.6

29.6

35.6

Injection timing adjustment_07

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

33.3

30.8

35.8

Injection timing adjustment_08

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

35.1

29.6

40.6

Injection quantity adjustment

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

14

12

16

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

10.5

9.5

11.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

5

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

9

12

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

20.5

14

27

Remarks

From idle

From idle

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

15.2

8.2

22.2

Remarks

From idle

From idle

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

438

306

570

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

421.5

392

451

Pressure with S/T ON

kgf/cm2

4.3

4

4.6

Pressure with S/T OFF

kPa

324

275

373

Pressure with S/T OFF

kgf/cm2

3.3

2.8

3.8

Basic

*

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

421.5

392

451

Pressure with S/T ON

kgf/cm2

4.3

4

4.6

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure with S/T ON

kPa

588.5

559

618

Pressure with S/T ON

kgf/cm2

6

5.7

6.3

Stop lever angle_04

Pump speed

r/min

2400

2400

2400

Pressure with S/T ON

kPa

725.5

686

765

Pressure with S/T ON

kgf/cm2

7.4

7

7.8

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.1

2.9

3.3

Timer stroke with S/T OFF

mm

1.1

0.7

1.5

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.1

2.8

3.4

Timer stroke with S/T OFF

mm

1.1

0.6

1.6

_03

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T ON

mm

6.8

6.2

7.4

_04

Pump speed

r/min

2400

2400

2400

Timer stroke with S/T ON

mm

8.5

8

9

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.78

6.68

6.88

MS dimension

mm

0.8

0.7

0.9

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

42

37

47

Control lever angle gamma

deg.

8.7

8.2

9.2

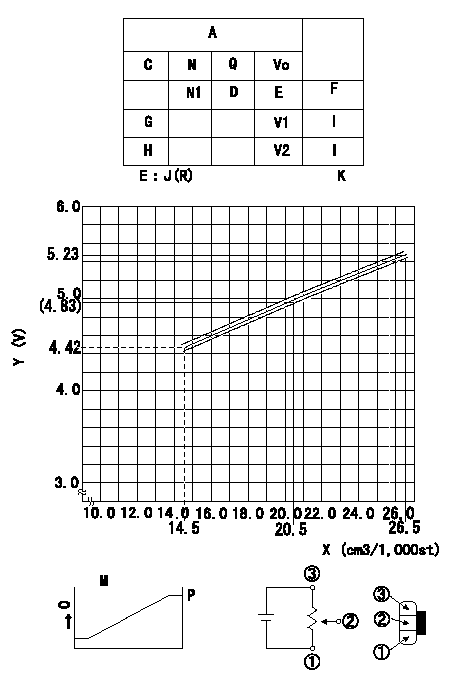

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula

G:Idle

H:Full speed

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

----------

N1=700r/min a=8.7deg L=5.6+-0.05mm Q1=15.1cm3/1,000st V3=4.46V

----------

N1=700r/min Q1=15.1cm3/1.000st V1=(2.34+-0.75)V V2=9.96++V V3=4.46V K=10V J:V+-0.03=0.06740X+3.4462

----------

N1=700r/min a=8.7deg L=5.6+-0.05mm Q1=15.1cm3/1,000st V3=4.46V

----------

N1=700r/min Q1=15.1cm3/1.000st V1=(2.34+-0.75)V V2=9.96++V V3=4.46V K=10V J:V+-0.03=0.06740X+3.4462

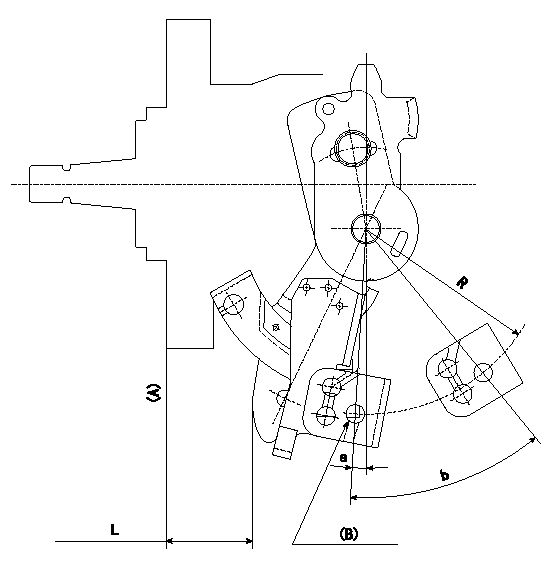

0000001901 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = pump flange face

(B) = lever angle measuring hole

Alpha = a

beta = b

----------

R=61mm L=25.7~29.7mm

----------

R=61mm L=25.7~29.7mm a=23~27deg b=37~47deg

----------

R=61mm L=25.7~29.7mm

----------

R=61mm L=25.7~29.7mm a=23~27deg b=37~47deg

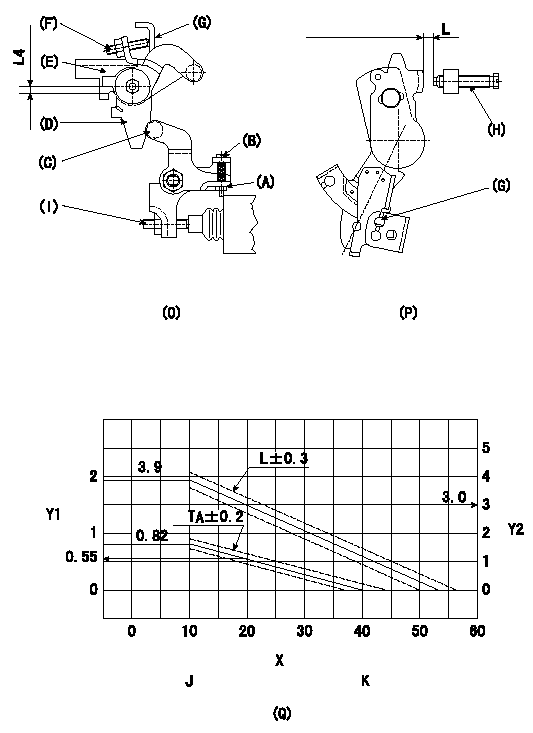

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle from the graph in Fig. 3 (Q).

(2)(1) Adjust using the screw (I) so that the timer advance angle determined in item (1) is obtained.

2. Setting the intermediate lever position (refer to fig 1 and fig 2)

(1)Insert a block gauge L1 between the idling set screw (H) and the control lever (G).

(2)Insert a shim of thickness L2 mm between the intermediate lever (D) and the intermediate lever bracket (E). Ensure the screw (F) contacts the control lever (G), then fix the nut.

3. W-CSD lever adjustment [refer to fig 1 (O) and fig 2 (P)]

(1)After completing (2) above, remove the block gauge L3 and the shim with the thickness L4.

(2)Insert a block gauge L5 determined from the graph (L-theta) in figure 3 (Q) between the idling set screw (H) and the control lever (G).

(3)Adjust the screw (B) until the screw (F) contacts the control lever (G). Then fix locknut (A).

Note:

The temperature of the wax at adjustment must not exceed a.

X:Temperature X (V)

Y1:Timer stroke TA (mm)

Y2:Control lever L dimension (mm; control lever position)

J:Graph TA-X:

X (deg C) <= 10: TA = 0.82

10 <= X (deg C) <= 20: TA =-0.027X + 1.09

20 <= X (deg C) < = 40 :TA =-0.0275X + 1.1

K:Graph L-X:

X (deg C) <= 10: L = 3.9

10 <= X (deg C) <= 30: L = -0.09X + 4.8

20 <= X (deg C) <= 54.3: L =-0.086X + 4.68

----------

L1=L=3.0+-0.05mm L2=5.3+-0.05mm L3=3mm L4=5.3mm L5=L+-0.05mm a=30degC

----------

L4=5.3mm

----------

L1=L=3.0+-0.05mm L2=5.3+-0.05mm L3=3mm L4=5.3mm L5=L+-0.05mm a=30degC

----------

L4=5.3mm

Have questions with 104740-2393?

Group cross 104740-2393 ZEXEL

104740-2393

INJECTION-PUMP ASSEMBLY