Rating:

Information injection-pump assembly

BOSCH

9 400 619 746

9400619746

ZEXEL

108822-3003

1088223003

HINO

220008103A

220008103a

Service parts 108822-3003 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

9.

_

11.

Nozzle and Holder

236002540B

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/23.5{240}

14.

NOZZLE

Include in #1:

108822-3003

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 746

9400619746

ZEXEL

108822-3003

1088223003

HINO

220008103A

220008103a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

42

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

6.4

6.37

6.43

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

209

207

211

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

212

209

215

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

212

209

215

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_04

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

135

125

145

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_05

Adjusting point

G

Rack position

3.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.5

9.5

15.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

6.3+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_06

Adjusting point

H

Rack position

-

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

263

258

268

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Rack limit

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

7.25

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

9.7

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

0000001601

Pre-stroke

mm

6.4

6.37

6.43

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

8.5

8

9

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

4

3.95

4.05

Output voltage

V

2.45

2.44

2.46

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.4

6.37

6.43

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

3.4

Output voltage

V

3

2.98

3

Confirmation

*

_06

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

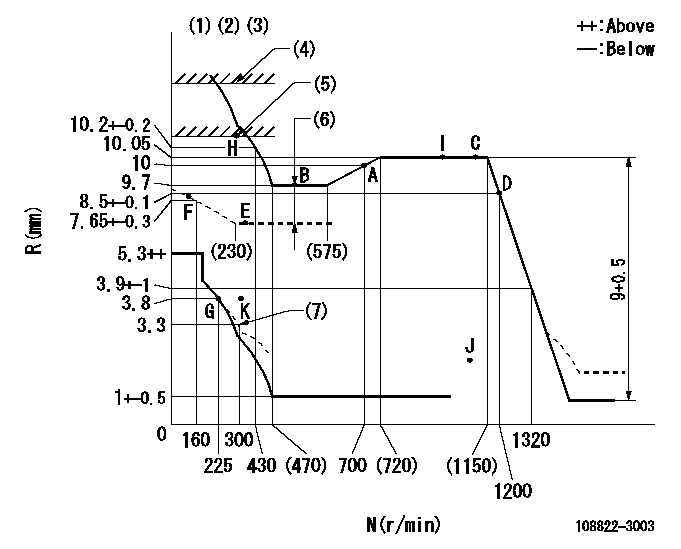

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Supplied with torque spring not set.

(3)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2). The pre-stroke at that time must be Pr1 (Pv1).

(4)Stop lever setting: R2

(5)RACK LIMIT

(6)Boost compensator stroke: BCL

(7)Damper spring setting

----------

N1=300r/min R1=3.8mm N2=1100r/min Q1=3mm3/st Pr1=4+-0.05mm Pv1=2.45+-0.01V R2=(13)+0.5mm BCL=2.45+-0.1mm

----------

----------

N1=300r/min R1=3.8mm N2=1100r/min Q1=3mm3/st Pr1=4+-0.05mm Pv1=2.45+-0.01V R2=(13)+0.5mm BCL=2.45+-0.1mm

----------

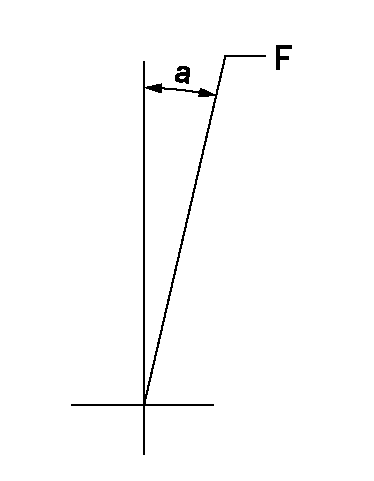

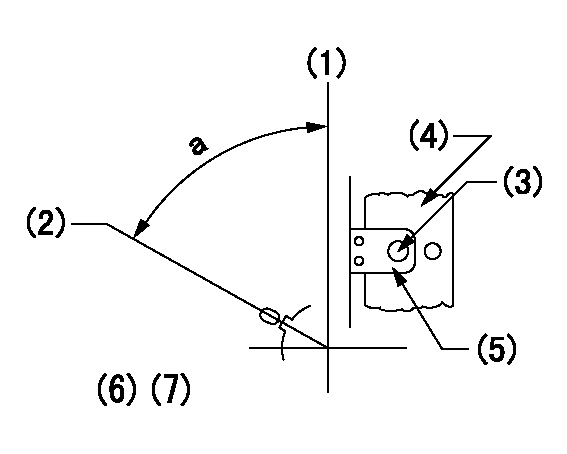

Speed control lever angle

F:Full speed

----------

----------

a=18deg+-5deg

----------

----------

a=18deg+-5deg

0000000901

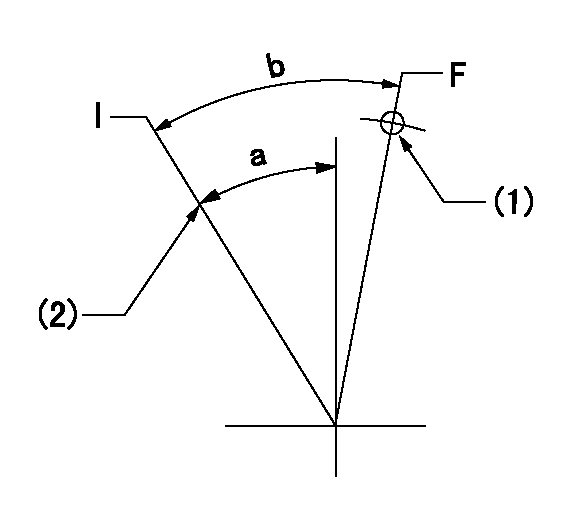

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=79mm

----------

a=24deg+-5deg b=31deg+-3deg

----------

aa=79mm

----------

a=24deg+-5deg b=31deg+-3deg

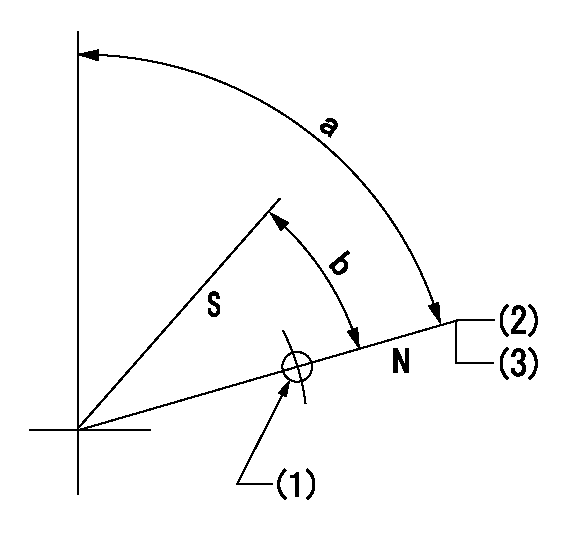

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set stopper screw so that rack position = bb (after setting apply red paint).

(3)Set before governor adjustment.

----------

aa=27.5mm bb=(13)+0.5mm

----------

a=82deg+-5deg b=45deg+-5deg

----------

aa=27.5mm bb=(13)+0.5mm

----------

a=82deg+-5deg b=45deg+-5deg

0000001301

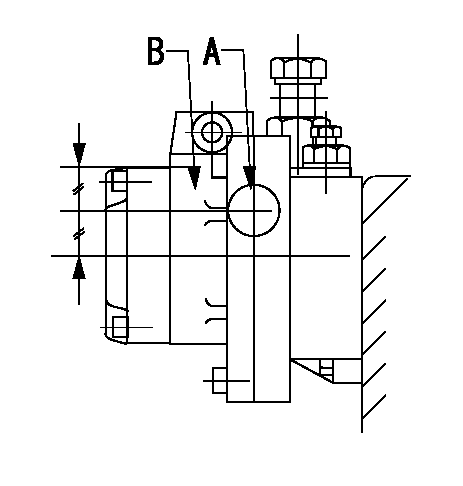

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)At the No 1 cylinder's beginning of injection position, stamp an aligning mark on the coupling to align with the pointer's groove.

(4)Coupling

(5)Pointer

(6)Pre-stroke: aa

(7)-

----------

aa=6.4+-0.03mm

----------

a=(80deg)

----------

aa=6.4+-0.03mm

----------

a=(80deg)

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

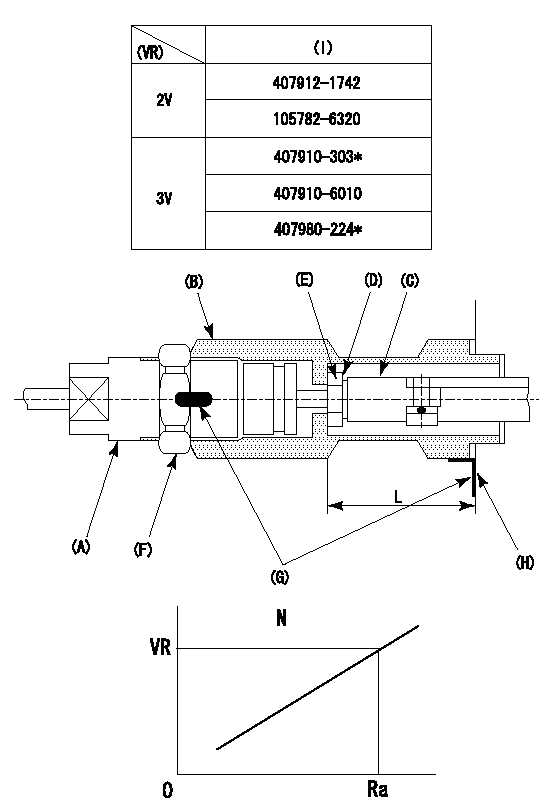

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Mount the joint (B).

(2)Select the shim (D) so that the rack limit's rack position is obtained at that time.

(3)Install the rod (E) to the block (C).

The distance between the pump end face and the rod (E) at rack limit must be L.

2. Rack sensor adjustment (-0020)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set at speed N.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.01 (V), then tighten the nut (F). (If equipped with a boost compensator, perform with boost pressure applied.)

(5)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(6)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=38-0.2mm N=900r/min Ra=(10.05)mm

----------

----------

L=38-0.2mm N=900r/min Ra=(10.05)mm

----------

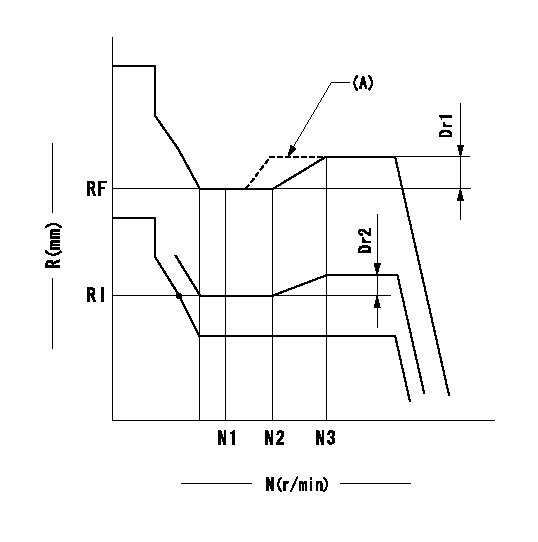

0000002301 GOVERNOR TORQUE CONTROL

Dr:Torque control stroke

(A): Without torque control spring capsule

1. Adjustment procedures

(1)Procedure is the same as that for the RFD (former type), except that the positive torque control stroke must be determined at the full lever setting.

2. Procedures for adjustment

(1)Remove the torque control spring capsule.

(2)Operate the pump at approximately N1. (End of idling spring operation < N1.)

(3)Tilt the lever to the full side.

(4)Set so that R = RF.

(5)Increase the speed by pushing in the screw (attached to the bracket on the rear of the tension lever) through the adjusting window.

(6)Adjust so that the torque control stroke Dr1 can be obtained.

(7)Align N2 and N3 with the torque control spring capsule.

3. Final confirmation

(1)After final confirmation, temporarily set the load lever to N = N1, R = idling position.

(2)From this condition, increase speed to N = N4.

(3)Confirm that positive torque control stroke is Dr2.

----------

N1=500r/min N2=(575)r/min N3=(720)r/min N4=1100r/min RF=9.7mm Dr1=0.35mm Dr2=0+0.3mm

----------

----------

N1=500r/min N2=(575)r/min N3=(720)r/min N4=1100r/min RF=9.7mm Dr1=0.35mm Dr2=0+0.3mm

----------