Information injection-pump assembly

BOSCH

9 400 618 677

9400618677

ZEXEL

106971-1192

1069711192

ISUZU

1156031772

1156031772

Rating:

Service parts 106971-1192 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106971-1192

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 677

9400618677

ZEXEL

106971-1192

1069711192

ISUZU

1156031772

1156031772

Zexel num

Bosch num

Firm num

Name

106971-1192

9 400 618 677

1156031772 ISUZU

INJECTION-PUMP ASSEMBLY

10PE1-S K

10PE1-S K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

5.5

5.47

5.53

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

141

139.4

142.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

6.7+-0.5

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

13.5

11.5

15.5

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

141

140

142

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.25

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

140.5

136.5

144.5

Fixing the lever

*

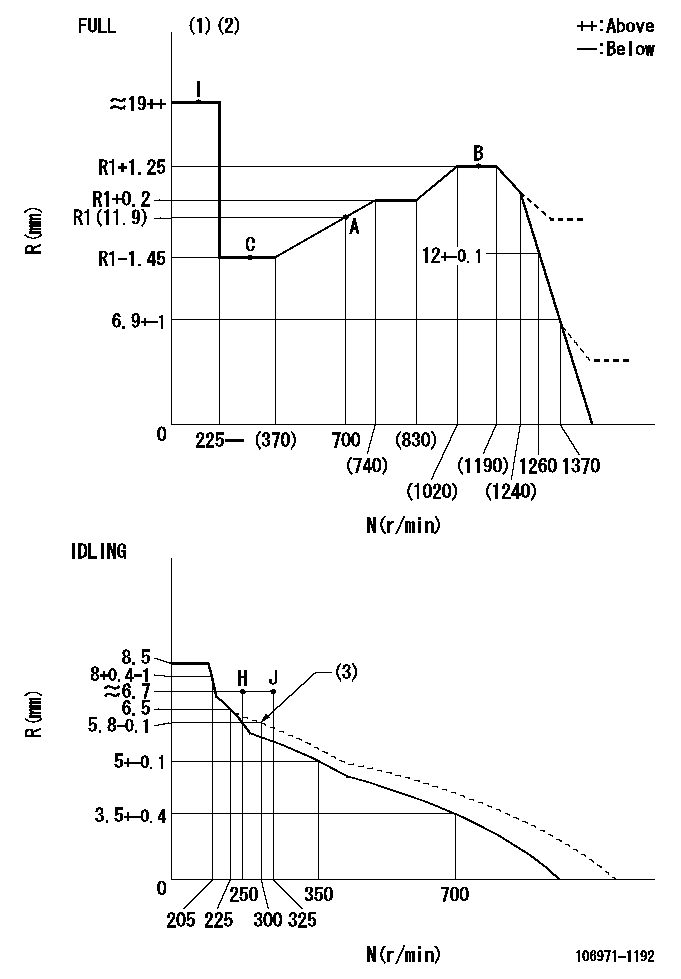

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AD38

----------

----------

T1=AD38

----------

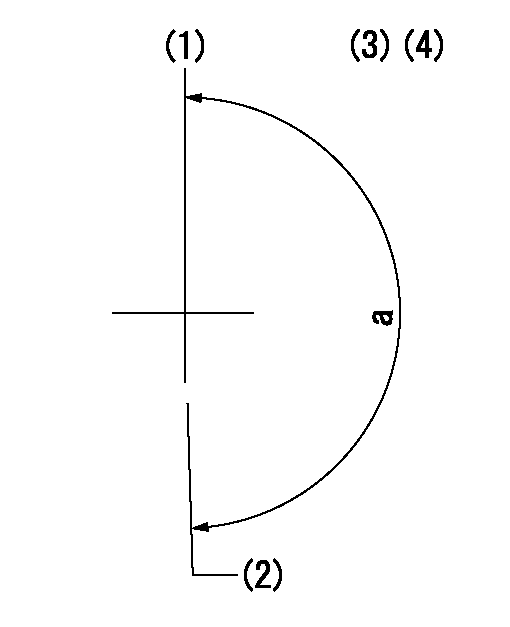

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=950++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(8)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=950++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8+-0.3deg R01=0/4load R02=4/4load

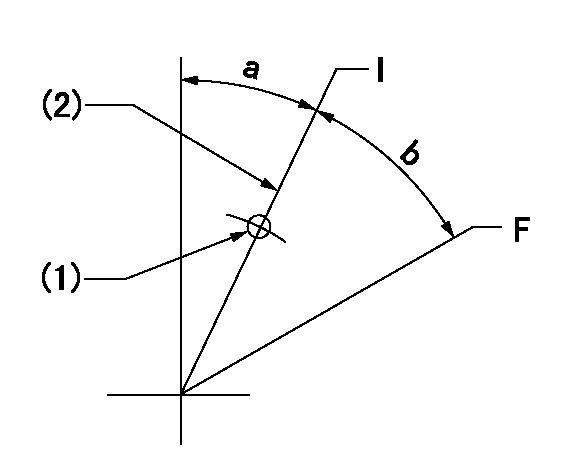

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=42.5mm

----------

a=22.5deg+-5deg b=(30deg)+-3deg

----------

aa=42.5mm

----------

a=22.5deg+-5deg b=(30deg)+-3deg

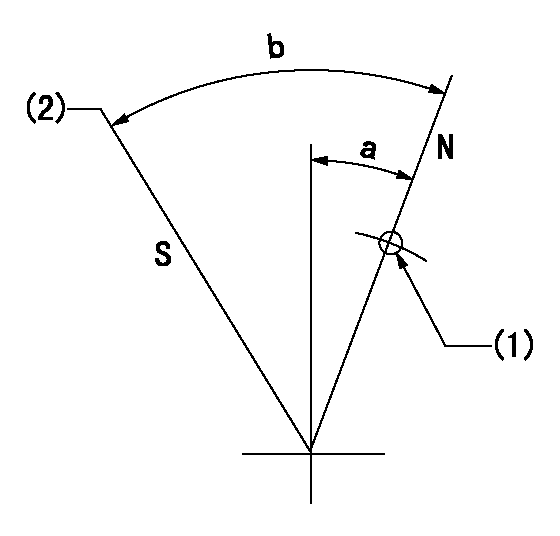

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=20deg+-5deg b=43deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=20deg+-5deg b=43deg+-5deg

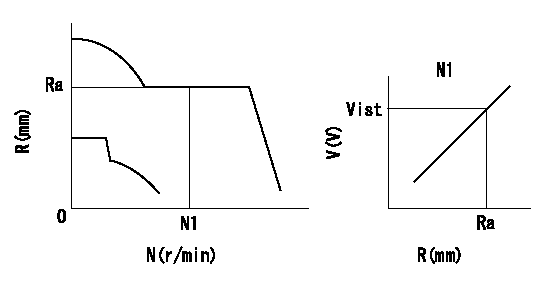

0000001501 RACK SENSOR

Rack sensor adjustment

1. Flange type rack sensor (rack sensor adjustment -5*20)

(1)These types of rack sensors do not need adjustment. Confirm the performance with the following procedures.

(2)Mount the rack sensor main body to the pump main body.

(3)Fix the pump lever at full.

(4)At supply voltage V1, pump speed N1 and rack position Ra, confirm that the amp's output voltage is Vist.

(5)Move the pump lever two or three times.

(6)Set again to full.

(7)Confirm that the amplifier output voltage is Vist.

(8)Fix the caution plate to the upper part of the rack sensor.

(For those without the caution plate instructions, make sure the nameplate of the rack sensor carries the "Don't hold here" caution.)

(9)Apply red paint to the rack sensor mounting bolts (2 places).

----------

V1=5+-0.01V N1=790r/min Ra=R1(11.9)+0.2mm Vist=1.53+-0.14V

----------

----------

V1=5+-0.01V N1=790r/min Ra=R1(11.9)+0.2mm Vist=1.53+-0.14V

----------

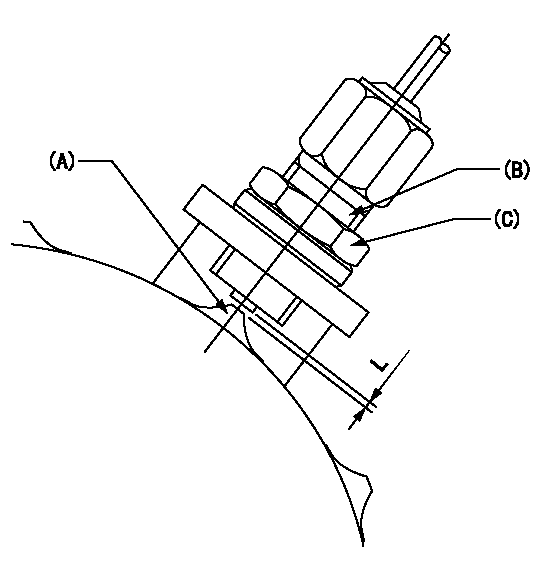

0000001601 SPEED SENSOR

(A) Flyweight projection

(B) Pickup sensor

(c) Lock nut

Speed sensor installation

(1)Install the speed sensor so that the clearance between the sensor and the flyweight projection is L.

(This gap is the gap when the pickup sensor is returned 1 turn from where it contacts the flyweight tooth.)

----------

L=0.8~1mm

----------

----------

L=0.8~1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=4deg

----------

a=(180deg)

----------

aa=4deg

----------

a=(180deg)

Information:

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

28Feb2007 31Aug2007

PROBLEM

The torque on the 100-6920 Direct Injection Fuel Nozzle Adapters may be out of specification.

AFFECTED PRODUCT

Model Identification Number

3408C TAM00350-00351

3412 38S24043

BCS02130

3412C 9BR03238

9EP03871, 3969-3970, 3972-3973

DJN01044-01070, 1074-1076, 1081, 1087

RLR00339, 341-342

TFT00565-00583

PARTS NEEDED

No parts needed for this program

ACTION REQUIRED

Remove valve covers, fuel lines and fuel nozzles. Tighten the 100-6920 Direct Injection Fuel Nozzle Adapters to 200 +/- 14 Nm (150 +/- 10 lb ft). Reassemble engine. For detailed instructions, refer to the procedure in the Disassembly and Assembly manual. Test engine for proper operation after reassembly.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 3.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR TIGHTENING THE DIRECT INJECTION FUEL NOZZLE ADAPTERS

MODELS INVOLVED - Certain 3408 and 3412 Engines

Dear Caterpillar Product Owner:

The torque on the Direct Injection Fuel Nozzle Adapters may be out of specification. The Direct Injection Fuel Nozzle Adapters need to be tightened to the correct torque on the products listed below. You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 24Aug2006 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 24Aug2006 Service Letter

Have questions with 106971-1192?

Group cross 106971-1192 ZEXEL

Isuzu

106971-1192

9 400 618 677

1156031772

INJECTION-PUMP ASSEMBLY

10PE1-S

10PE1-S