Rating:

Information injection-pump assembly

ZEXEL

106693-1880

1066931880

ISUZU

1156025090

1156025090

Service parts 106693-1880 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-128-2

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Include in #1:

106693-1880

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106693-1880

1066931880

ISUZU

1156025090

1156025090

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.97

3.03

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

6.8

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

118

116

120

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

97.7

95.7

99.7

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

4.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13

9.8

16.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

E

Rack position

7.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

109.6

106.6

112.6

Fixing the lever

*

Remarks

Startup boost setting

Startup boost setting

Injection quantity adjustment_05

Adjusting point

F

Rack position

7.2+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

101.4

98.4

104.4

Fixing the lever

*

Timer adjustment

Pump speed

r/min

900+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

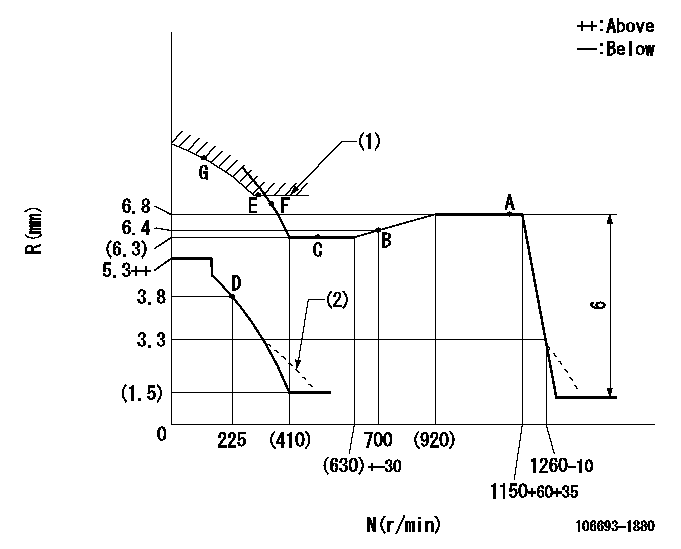

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting: DL

----------

SXL=(7.7)+-0.1mm DL=3.3-0.5mm

----------

----------

SXL=(7.7)+-0.1mm DL=3.3-0.5mm

----------

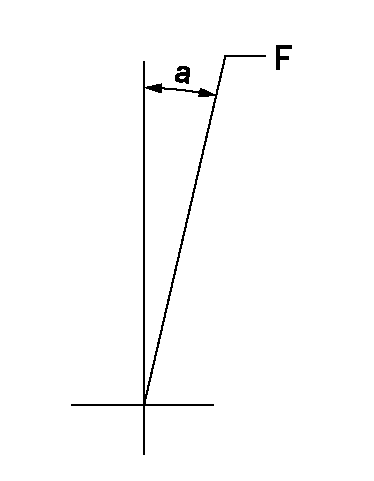

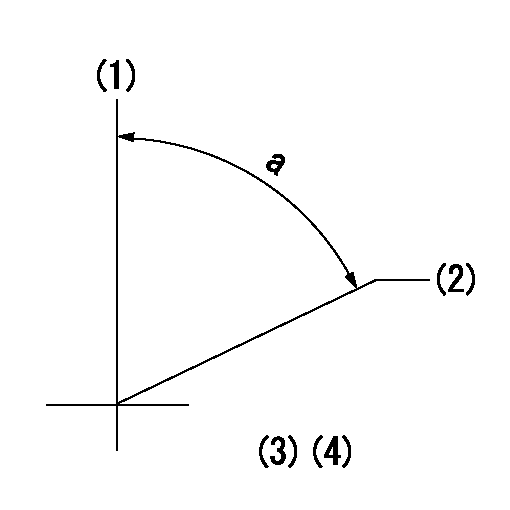

Speed control lever angle

F:Full speed

----------

----------

a=5deg+-5deg

----------

----------

a=5deg+-5deg

0000000901

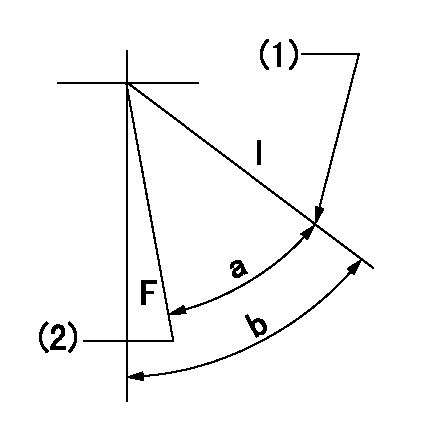

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Attach the return spring to the bottom hole and adjust.

----------

----------

a=(26deg)+-3deg b=55deg+-5deg

----------

----------

a=(26deg)+-3deg b=55deg+-5deg

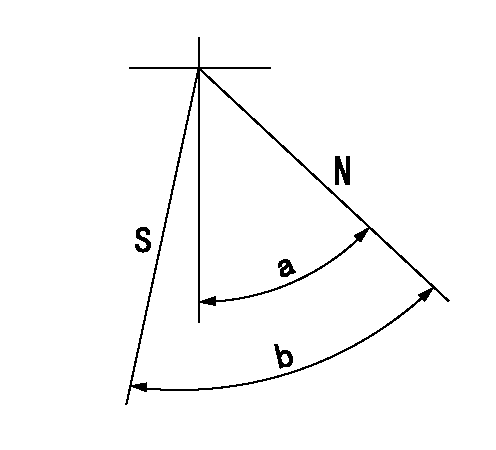

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=52deg+-5deg b=64deg+-5deg

----------

----------

a=52deg+-5deg b=64deg+-5deg

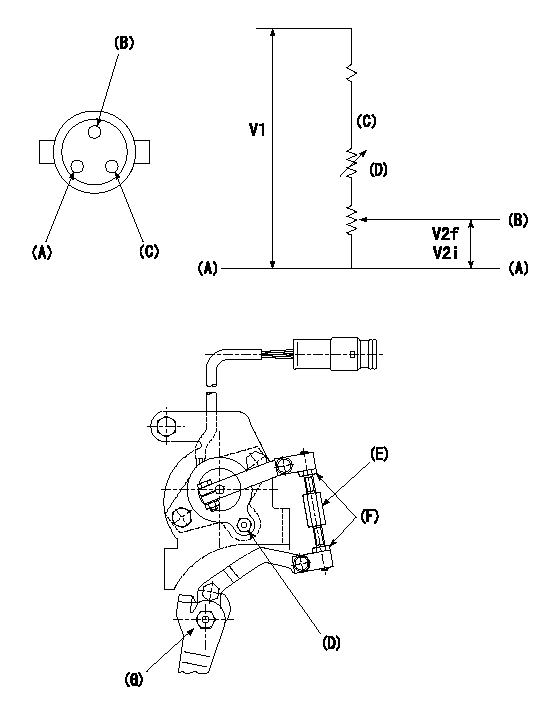

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+-0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+-0.03V V2i=2.35-0.03V

----------

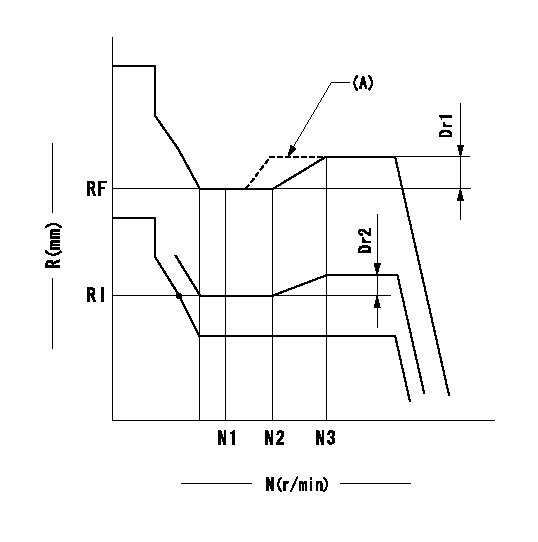

0000001601 GOVERNOR TORQUE CONTROL

Dr:Torque control stroke

(A): Without torque control spring capsule

1. Adjustment procedures

(1)Procedure is the same as that for the RFD (former type), except that the positive torque control stroke must be determined at the full lever setting.

2. Procedures for adjustment

(1)Remove the torque control spring capsule.

(2)Operate the pump at approximately N1. (End of idling spring operation < N1.)

(3)Tilt the lever to the full side.

(4)Set so that R = RF.

(5)Increase the speed by pushing in the screw (attached to the bracket on the rear of the tension lever) through the adjusting window.

(6)Adjust so that the torque control stroke Dr1 can be obtained.

(7)Align N2 and N3 with the torque control spring capsule.

3. Final confirmation

(1)After final confirmation, temporarily set the load lever to N = N1, R = idling position.

(2)From this condition, increase speed to N = N4.

(3)Confirm that positive torque control stroke is Dr2.

----------

N1=500r/min N2=(630)+-30r/min N3=(920)r/min N4=1100r/min RF=(6.3)mm Dr1=0.5mm Dr2=0+0.3mm

----------

----------

N1=500r/min N2=(630)+-30r/min N3=(920)r/min N4=1100r/min RF=(6.3)mm Dr1=0.5mm Dr2=0+0.3mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)