Rating:

Information injection-pump assembly

ZEXEL

104749-2610

1047492610

NISSAN

167001C515

167001c515

Cross reference number

ZEXEL

104749-2610

1047492610

NISSAN

167001C515

167001c515

Zexel num

Bosch num

Firm num

Name

104749-2610

167001C515 NISSAN

INJECTION-PUMP ASSEMBLY

LD20 * K

LD20 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

34.3

33.9

34.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

52

50

54

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

31.3

29.3

33.3

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

32

30

34

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

33.1

31.1

35.1

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

34.3

33.3

35.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

22.3

20.3

24.3

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

22.3

18.8

25.8

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

6.1

8.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.1

5.1

9.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

13.9

9.4

18.4

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Boost compensator adjustment_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

9.7

5.2

14.2

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

5.95

5.9

6

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

50

70

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

330

200

460

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

343

314

372

Pressure

kgf/cm2

3.5

3.2

3.8

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

343

304

382

Pressure

kgf/cm2

3.5

3.1

3.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

539.5

500

579

Pressure

kgf/cm2

5.5

5.1

5.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2300

2300

2300

Pressure

kPa

647

608

686

Pressure

kgf/cm2

6.6

6.2

7

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.2

1.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Timer stroke

mm

3.2

2.8

3.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2300

2300

2300

Timer stroke

mm

8.55

8.1

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

41

36

46

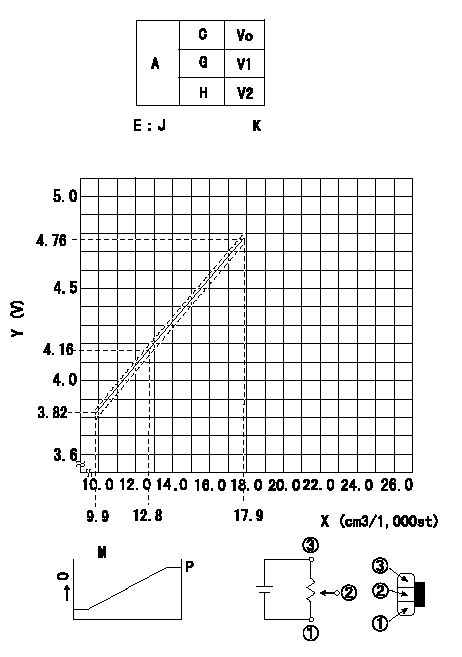

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

At N = N1 and control lever position a (corresponding to shim thickness L), measure the injection quantity, calculate the voltage from the graph, and then adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula (J)

G:Idle

H:Full speed

K:Applied voltage

X:Injection quantity (mm3/st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

----------

N1=600r/min a=11deg L=5.95+-0.05mm

----------

V1=(1.15+-0.75)V V2=Above(9.96)V E=V+-0.03=0.1169X+2.664

----------

N1=600r/min a=11deg L=5.95+-0.05mm

----------

V1=(1.15+-0.75)V V2=Above(9.96)V E=V+-0.03=0.1169X+2.664

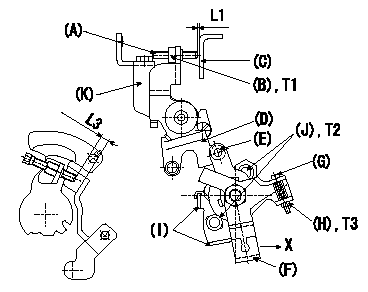

0000001901 M-CSD ADJUSTMENT

M-CSD adjustment

1. Fixing intermediate lever screw (A) [roller (E) must not contact intermediate lever (D)]

(1)Hold the control lever C in the idling position.

(2)At this time, adjust intermediate lever screw (A) so that it is horizontal and the clearance between intermediate lever (A) and the control lever (C) is L1. Then, fix using nut (B).

2. Fixing the M-CSD stopper (I)

Pull the CSD lever (F) in direction X until it contacts the M-CSD stopper (I) and tighten the socket head bolt (J) in the position where the timer stroke is L2

3. Screw (G) adjustment

Pull the CSD lever (F) toward X until it contacts the stopper (I). At this time, adjust the screw (G) so that the control lever shim thickness is L3, then tighten using the nut (H).

----------

L1=1~2mm L2=1.23+-0.2mm L3=5.8+-0.05mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=4.9~7N-m(0.5~0.7kgf-m) T3=2~2.9N-m(0.2~0.3kgf-m) L1=1~2mm L3=5.8+-0.05mm

----------

L1=1~2mm L2=1.23+-0.2mm L3=5.8+-0.05mm

----------

T1=6~9N-m(0.6~0.9kgf-m) T2=4.9~7N-m(0.5~0.7kgf-m) T3=2~2.9N-m(0.2~0.3kgf-m) L1=1~2mm L3=5.8+-0.05mm

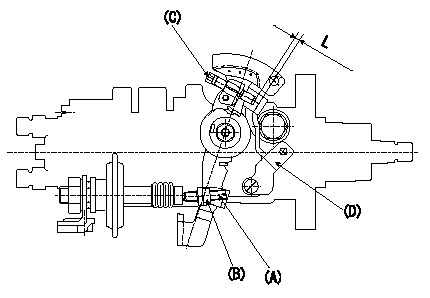

0000002001 DASHPOT ADJUSTMENT

Adjustment of the dash pot

1. Insert a block gauge L (thickness gauge) between the idle set screw (C) and the control lever (D).

2. In the above condition, adjust the dashpot adjusting screw (A) so that it contacts the pushrod, and then fix it using the locknut (B).

Note:

(1)The adjusting screw and pushrod contact faces must be smooth.

(2)Confirm that the control lever returns to the idling position.

----------

L=3.8+-0.05mm

----------

L=3.8+-0.05mm

----------

L=3.8+-0.05mm

----------

L=3.8+-0.05mm

Have questions with 104749-2610?

Group cross 104749-2610 ZEXEL

Nissan

104749-2610

167001C515

INJECTION-PUMP ASSEMBLY

LD20

LD20