Rating:

Information injection-pump assembly

ZEXEL

104749-0330

1047490330

MAZDA

PN2313800

pn2313800

Cross reference number

ZEXEL

104749-0330

1047490330

MAZDA

PN2313800

pn2313800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

36.1

35.6

36.6

Difference in delivery

mm3/st.

2.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

8

5

11

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

32.2

30.2

34.2

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

36.1

35.1

37.1

Injection timing adjustment_05

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

35.4

31.4

39.4

Injection quantity adjustment

Pump speed

r/min

2635

2635

2635

Average injection quantity

mm3/st.

8

6

10

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

3

Governor adjustment

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

6

5

7

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

6

5

7

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

55

75

Basic

*

Speed control lever angle

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1500

1500

1500

Overflow quantity

cm3/min

450

318

582

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Basic

*

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

323.5

294

353

Pressure

kgf/cm2

3.3

3

3.6

Stop lever angle_03

Pump speed

r/min

1500

1500

1500

Pressure

kPa

460.5

431

490

Pressure

kgf/cm2

4.7

4.4

5

Stop lever angle_04

Pump speed

r/min

2350

2350

2350

Pressure

kPa

696.5

667

726

Pressure

kgf/cm2

7.1

6.8

7.4

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

3.9

3.7

4.1

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.6

1

2.2

_03

Pump speed

r/min

1500

1500

1500

Timer stroke

mm

3.9

3.6

4.2

_04

Pump speed

r/min

2350

2350

2350

Timer stroke

mm

7.7

7.1

8.3

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

32.2

31.2

33.2

Timer stroke TA

mm

3.2

3

3.4

Basic

*

_02

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

32.2

30.7

33.7

Timer stroke TA

mm

3.2

2.9

3.5

_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

23.1

21.6

24.6

Timer stroke TA

mm

2.2

2.2

2.2

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.5

1.4

1.6

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

43

38

48

Test data Ex:

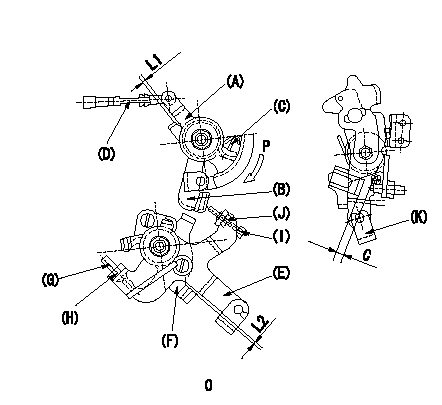

0000001801 M-CSD ADJUSTMENT

M-CSD adjustment

1. Adjusting and fixing the side link lever

(1)With the control lever on top of the pump positioned at a, move the side link lever B to contact the stopper C.

(2)Turn lever (A) lightly in the direction P so that there is no play in connecting rod (D). (Control lever remains at b.)

(3)Adjust the length of the rod (D) so that the distance between the lever (A) and the side link lever (B) is L1, then fix.

2. Fixing the M-CSD

(1)With the roller holder advanced c, adjust the lever shaft ball pin so that it contacts the roller holder.

(2)At this time, adjust the position of the M-CSD lever (E) using adjusting screw (G) so that the clearance between the M-CSD lever (E) and the stopper (F) becomes L2. Then fix using nut (H).

Tighten nut (H) to torque T1.

2. M-FICD adjustment

(1)Move the CSD lever (E) through its full stroke [until it contacts the other end of the stopper (F)].

(2)Adjust screw (I) so that the control lever (K)'s position is d (C), then fix using the nut (J).

Tighten nut (H) to torque T2.

O = at idle to d, C

----------

L1=0.8+-0.2mm L2=0.5+2mm a=0deg b=0deg c=0deg d=9.5deg C=4.1+-0.5mm T1=6~9N-m{0.6~0.9kgf-m} T2=3.5~5N-m{0.35~0.5kgf-m}

----------

L1=0.8+-0.2mm L2=0.5+2mm

----------

L1=0.8+-0.2mm L2=0.5+2mm a=0deg b=0deg c=0deg d=9.5deg C=4.1+-0.5mm T1=6~9N-m{0.6~0.9kgf-m} T2=3.5~5N-m{0.35~0.5kgf-m}

----------

L1=0.8+-0.2mm L2=0.5+2mm