Rating:

Information injection-pump assembly

ZEXEL

104742-7681

1047427681

KOMATSU

6274711220

6274711220

Cross reference number

ZEXEL

104742-7681

1047427681

KOMATSU

6274711220

6274711220

Zexel num

Bosch num

Firm num

Name

104742-7681

6274711220 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA4D95LE

SAA4D95LE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Timer measuring device installation position

Low pressure side LOW PRESSURE SIDE

Low pressure side LOW PRESSURE SIDE

Injection timing adjustment

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

73.3

72.8

73.8

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

110.2

109.7

110.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

117.9

117.4

118.4

Difference in delivery

mm3/st.

9.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

73.3

72.3

74.3

Basic

*

Oil temperature

degC

48

46

50

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

800

800

800

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

110.2

108.7

111.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

117.9

116.4

119.4

Difference in delivery

mm3/st.

10

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

122.1

116.1

128.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1253

1253

1253

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

30.8

26.8

34.8

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1428

1428

1428

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1253

1253

1253

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

30.8

26.3

35.3

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

418

418

418

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.2

5.2

9.2

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

418

418

418

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.2

4.7

9.7

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

130.5

125.5

135.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

130.5

125.5

135.5

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

418

418

418

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

630

500

760

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

402

382

422

Pressure

kgf/cm2

4.1

3.9

4.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Stop lever angle_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

275

226

324

Pressure

kgf/cm2

2.8

2.3

3.3

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

373

324

422

Pressure

kgf/cm2

3.8

3.3

4.3

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

402

373

431

Pressure

kgf/cm2

4.1

3.8

4.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

0000001101

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

0.7

0.5

0.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

0.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

0.7

0.4

1

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

21

20

22

Timer stroke TA

mm

1.6

1.3

1.9

Timer stroke variation dT

mm

1.6

1.6

1.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Reverse operation

Reverse operation

_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

21

19.5

22.5

Timer stroke TA

mm

1.6

1.2

2

Timer stroke variation dT

mm

1.6

1.6

1.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Reverse operation

Reverse operation

_03

Pump speed

r/min

800

800

800

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

10

8

12

Timer stroke TA

mm

2

2

Timer stroke variation dT

mm

2

2

Oil temperature

degC

50

48

52

Remarks

Reverse operation

Reverse operation

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1.4

1.3

1.5

BCS stroke

mm

2.7

2.5

2.9

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

29

24

34

Test data Ex:

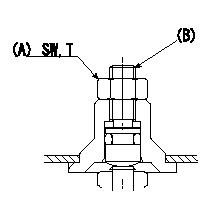

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=800r/min N2=500r/min P1=40.0kPa(300mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=800r/min N2=500r/min P1=40.0kPa(300mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

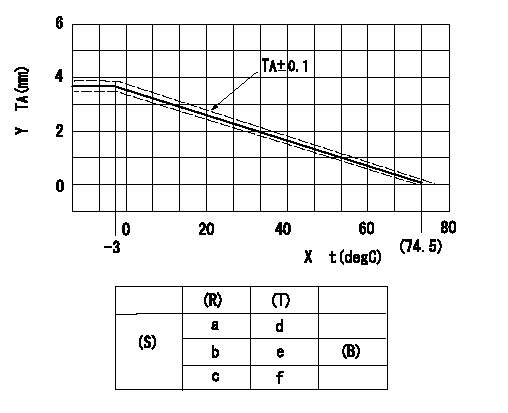

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

1. Determine the timer advance angle using the graph (graph TA).

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

TA=-0.053t+3.881 -3<=t<=20 TA=-0.0517t+3.854 20<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

----------

TA=-0.053t+3.881 -3<=t<=20 TA=-0.0517t+3.854 20<=t

----------

a=76.5++degC b=20degC c=-3degC d=0mm e=2.82+-0.4mm f=4.04+-0.6mm

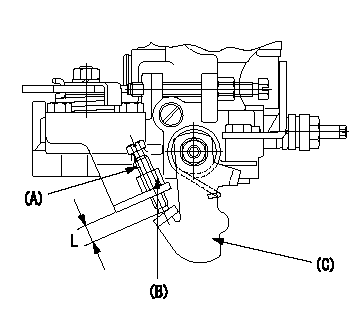

0000001901 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

Adjust using the screw (A) so that the standards are satisfied, then fix using the nut (B).

Screw (A) protrusion: L

(B) Nut (SW10, T1 after completing adjustment)

(C) Stop lever

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T1=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

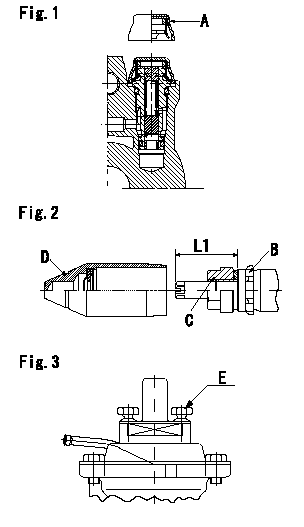

0000002001 TAMPER PROOF

Tamperproof installation procedure

A:Cap

B:Rubber vibration damper

C:Nut

D:Cap

E:Position of break

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Insert the cap A horizontally (press fit).

2) After insertion (press-fitting), tighten the cap to torque T1, and confirm that it is not pulled out at load F1.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T2.

Fig. 3 External-adjustment type cover governor seal

1) Target breaking torque T3

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m) T3=2.94~4.41N-m(0.3~0.45kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm F1=49N(5kgf) T1=4.9N-m(0.5kgf-m) T2=7~9N-m(0.7~0.9kgf-m) T3=2.94~4.41N-m(0.3~0.45kgf-m)

----------

L1=23~28mm

Have questions with 104742-7681?

Group cross 104742-7681 ZEXEL

Komatsu

Yanmar

Komatsu

Yanmar

Komatsu

104742-7681

6274711220

INJECTION-PUMP ASSEMBLY

SAA4D95LE

SAA4D95LE