Rating:

Information injection-pump assembly

ZEXEL

104741-8121

1047418121

MITSUBISHI

ME444303

me444303

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel High Pressure Fuel Pump 104641-8121, ME444303 Compatible For MITSUBISHI 4M40

IAVJPUK High precision: It can accurately control the injection amount and injection time of fuel to adapt to different engine operating conditions || Good atomization performance: atomizes fuel into small particles to improve combustion efficiency || Quick response: able to quickly perform fuel injection operations according to the instructions of the engine control unit, timely meeting the power demand of the engine || Wear resistance: It is usually made of wear-resistant materials to withstand the impact of high-pressure fuel and frequent working cycles || Diesel High Pressure Fuel Pump 104641-8121, ME444303 Compatible for MITSUBISHI 4M40

IAVJPUK High precision: It can accurately control the injection amount and injection time of fuel to adapt to different engine operating conditions || Good atomization performance: atomizes fuel into small particles to improve combustion efficiency || Quick response: able to quickly perform fuel injection operations according to the instructions of the engine control unit, timely meeting the power demand of the engine || Wear resistance: It is usually made of wear-resistant materials to withstand the impact of high-pressure fuel and frequent working cycles || Diesel High Pressure Fuel Pump 104641-8121, ME444303 Compatible for MITSUBISHI 4M40

Compatible for 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

IAVJPUK Precise fuel injection: It can inject fuel into specific positions in the cylinder with high precision, achieving more efficient combustion || Optimize combustion efficiency: Improve the adequacy of combustion, thereby enhancing the power output and torque performance of the engine || Reduce fuel consumption: Accurately control the fuel injection quantity to effectively improve fuel economy || Reduce exhaust emissions: More precise fuel injection can reduce the amount of unburned fuel and emissions, which is beneficial for environmental protection || Compatible for 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

IAVJPUK Precise fuel injection: It can inject fuel into specific positions in the cylinder with high precision, achieving more efficient combustion || Optimize combustion efficiency: Improve the adequacy of combustion, thereby enhancing the power output and torque performance of the engine || Reduce fuel consumption: Accurately control the fuel injection quantity to effectively improve fuel economy || Reduce exhaust emissions: More precise fuel injection can reduce the amount of unburned fuel and emissions, which is beneficial for environmental protection || Compatible for 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

Cross reference number

ZEXEL

104741-8121

1047418121

MITSUBISHI

ME444303

me444303

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.8

63.3

64.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

63.2

59.2

67.2

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

62.6

58.6

66.6

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.8

62.8

64.8

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

64.6

62.1

67.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

23.9

21.4

26.4

Difference in delivery

mm3/st.

7.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

23.9

20.9

26.9

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

19.6

17.6

21.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment_02

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

19.6

17.1

22.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

145

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

145

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

710

580

840

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

559

539

579

Pressure

kgf/cm2

5.7

5.5

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

800

800

800

Pressure

kPa

520

471

569

Pressure

kgf/cm2

5.3

4.8

5.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

900

900

900

Pressure

kPa

559

530

588

Pressure

kgf/cm2

5.7

5.4

6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1000

1000

1000

Pressure

kPa

598

549

647

Pressure

kgf/cm2

6.1

5.6

6.6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.1

1.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.9

2.4

3.3

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

57

53

61

Control lever angle beta

deg.

25

20

30

Test data Ex:

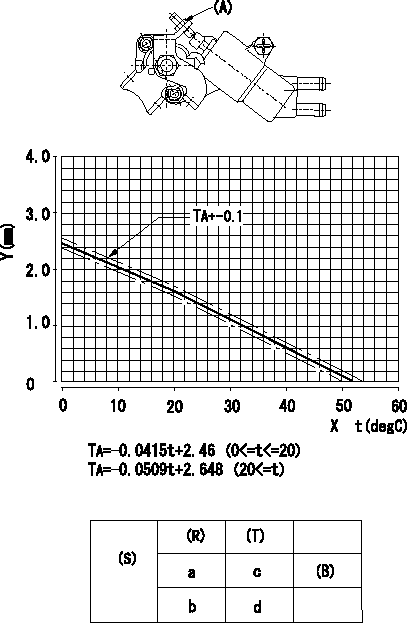

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke

1. Adjust the timer stroke B so that it is as described in the graph. (graph TA)

2) Adjust using screw (A) to obtain the timer stroke determined in step 1.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

----------

a=20degC b=0degC c=1.63+-4mm d=2.46+-0.6mm

----------

----------

a=20degC b=0degC c=1.63+-4mm d=2.46+-0.6mm

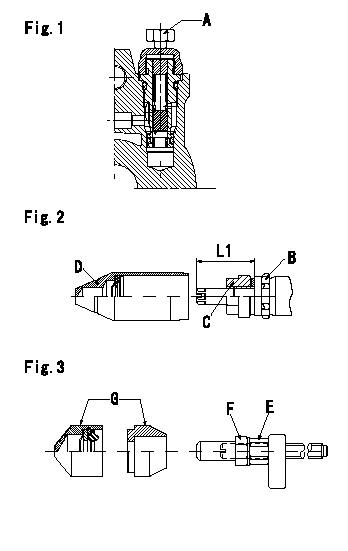

0000001901 TAMPER PROOF

Tamperproof installation procedure

A:Position of break

B:Rubber vibration damper

C:Nut

D:Cap

E:Nut

F:Nut

G:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Target breaking torque T1

2) Maximum allowable breaking torque T2

3) Because the cap and the regulating valve are fixed using the MEC process, the bolt cannot be loosened after the bolt has been broken.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T3.

Fig. 3 Maximum speed adjusting screw

1) Tighten nut (E) to the torque T4.

2) To prevent nut (E) from turning together, fix (E) using the tool, then tighten nut (F) to torque T4.

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm