Rating:

Information injection-pump assembly

ZEXEL

104741-1740

1047411740

Cross reference number

ZEXEL

104741-1740

1047411740

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

51.1

50.6

51.6

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

63.3

62.8

63.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

36.9

32.9

40.9

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

24

22.7

25.3

Boost pressure

mmHg

180

170

190

Average injection quantity

mm3/st.

40.5

38.5

42.5

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

51.1

50.1

52.1

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

63.3

62.3

64.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

56.7

53.2

60.2

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.2

19.2

25.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

11

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.2

19.2

25.2

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5.1

3.1

7.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5.1

3.1

7.1

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

530

510

550

Pressure with S/T OFF

kgf/cm2

5.4

5.2

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

550

550

550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

78

78

Pressure with S/T OFF

kgf/cm2

0.8

0.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

451

422

480

Pressure with S/T OFF

kgf/cm2

4.6

4.3

4.9

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

530

510

550

Pressure with S/T OFF

kgf/cm2

5.4

5.2

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

2050

2050

2050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

647

618

676

Pressure with S/T OFF

kgf/cm2

6.6

6.3

6.9

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

550

550

550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

2.5

2.1

2.9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2050

2050

2050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

8.6

8.3

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.5

4.4

4.6

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

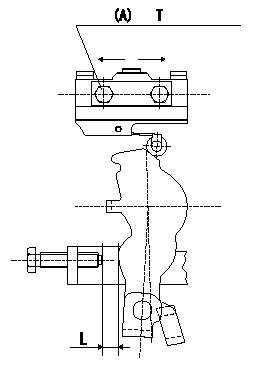

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1. Insert a shim L mm (control lever position: a) between the control lever and the idling stopper bolt.

2. Move the microswitch in the direction of the arrow so that it turns ON.

3. Move the microswitch again in the direction of the arrow and tighten the microswitch fixing bolt where it turns OFF.

Must change from ON to OFF at L1. [Lever angle b (from idle).]

(A): microswitch fixing bolt

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

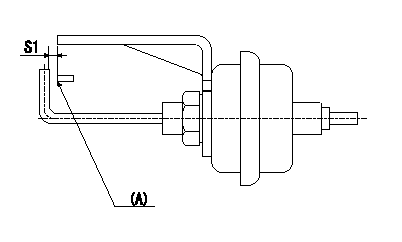

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm