Rating:

Information injection-pump assembly

ZEXEL

104741-1410

1047411410

ISUZU

8944528310

8944528310

Cross reference number

ZEXEL

104741-1410

1047411410

ISUZU

8944528310

8944528310

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

OFF OFF

OFF OFF

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

49.5

49

50

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.2

61.7

62.7

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

42.9

39.4

46.4

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

27.3

26

28.6

Boost pressure

mmHg

205

195

215

Average injection quantity

mm3/st.

42.3

42.3

42.3

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

49.5

48.5

50.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.2

61.2

63.2

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

53.2

49.2

57.2

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

27.5

24.5

30.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

13

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

27.5

24.5

30.5

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

9

7

11

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

9

7

11

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

95

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

75

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

608

579

637

Pressure with S/T OFF

kgf/cm2

6.2

5.9

6.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1020

1020

1020

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

7.8

7.5

8.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

3.2

3

3.4

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

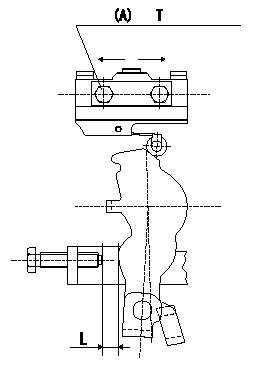

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1.Fix the control lever so that the distance between the control lever and the idling stopper bolt is L (control lever position: a).

2. In the above condition, adjust the installation position of the microswitch so that so that it turns OFF.

(A) = microswitch fixing bolt

----------

L=6.0+-0.2mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0+-0.2mm

----------

L=6.0+-0.2mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0+-0.2mm

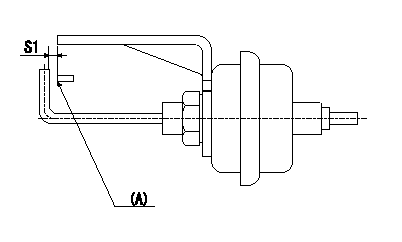

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm