Rating:

Information injection-pump assembly

ZEXEL

104740-8660

1047408660

MITSUBISHI

ME200202

me200202

Cross reference number

ZEXEL

104740-8660

1047408660

MITSUBISHI

ME200202

me200202

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

62.7

62.2

63.2

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

60.2

57.7

62.7

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

62.7

61.7

63.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

61.6

61.6

64.1

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

60.1

57.1

63.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

30.5

27.5

33.5

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

30.5

25.5

35.5

Difference in delivery

mm3/st.

9.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

48

38

58

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

48

38

58

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

830

700

960

Overflow quantity with S/T OFF

cm3/min

910

780

1040

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

559

530

588

Pressure with S/T ON

kgf/cm2

5.7

5.4

6

Pressure with S/T OFF

kPa

471

451

491

Pressure with S/T OFF

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

700

700

700

Pressure with S/T ON

kPa

431

382

480

Pressure with S/T ON

kgf/cm2

4.4

3.9

4.9

Pressure with S/T OFF

kPa

314

265

363

Pressure with S/T OFF

kgf/cm2

3.2

2.7

3.7

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

500

451

549

Pressure with S/T ON

kgf/cm2

5.1

4.6

5.6

Pressure with S/T OFF

kPa

412

373

451

Pressure with S/T OFF

kgf/cm2

4.2

3.8

4.6

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

559

520

598

Pressure with S/T ON

kgf/cm2

5.7

5.3

6.1

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

1500

1500

1500

Pressure with S/T ON

kPa

618

569

667

Pressure with S/T ON

kgf/cm2

6.3

5.8

6.8

Pressure with S/T OFF

kPa

530

481

579

Pressure with S/T OFF

kgf/cm2

5.4

4.9

5.9

Oil temperature

degC

50

48

52

Stop lever angle_06

Pump speed

r/min

2000

2000

2000

Pressure with S/T OFF

kPa

628

579

677

Pressure with S/T OFF

kgf/cm2

6.4

5.9

6.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.4

4

4.8

Timer stroke with S/T OFF

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke with S/T ON

mm

2

1.3

2.7

Timer stroke with S/T OFF

mm

0.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.4

3.8

5

Timer stroke with S/T OFF

mm

2.9

2.5

3.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke with S/T OFF

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

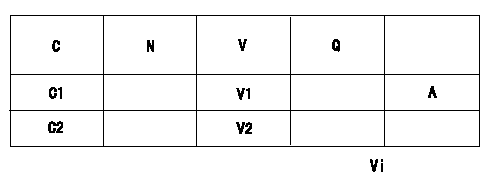

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Vi:Applied voltage

C:Position of the control lever

N:Pump speed

V:Output voltage

Q:Injection quantity

A:Adjusting point

C1:Idling

C2:Full speed

----------

----------

V1=1.6+-0.03(V) V2=(8.6(V)) Vi=10(V)

----------

----------

V1=1.6+-0.03(V) V2=(8.6(V)) Vi=10(V)

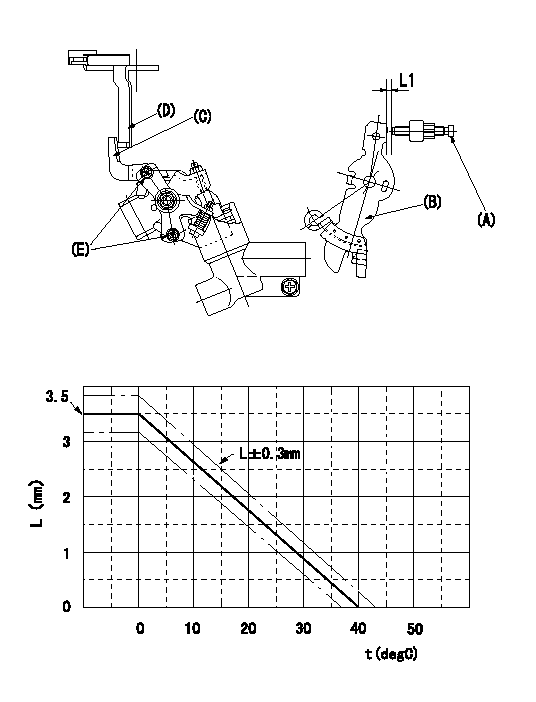

0000001901 W-FICD LEVER ADJUSTMENT

2. W-FICD (E) adjustment

(1)Insert a block gauge L1 determined from the graph between the control lever (B) and the idling set screw (A).

Graph for calculating L (mm) L = -0.088t+3.5

(2)Fix bolt (E) in the position where W-FICD lever (C) contacts the control lever (D). (Tighten to torque T.)

(3)The temperature of the wax at adjustment must not exceed a.

t:Temperature

L:Control lever L dimension (control lever position)

----------

L1=L+-0.3(mm) T=3.4~4.9(Nm)(0.35~0.5(kgfm)) a=35(degC)

----------

L1=L+-0.3(mm)

----------

L1=L+-0.3(mm) T=3.4~4.9(Nm)(0.35~0.5(kgfm)) a=35(degC)

----------

L1=L+-0.3(mm)