Rating:

Information injection-pump assembly

BOSCH

9 400 616 194

9400616194

ZEXEL

101701-9470

1017019470

NISSAN-DIESEL

16801Z6000

16801z6000

Service parts 101701-9470 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)/17.7(180)

14.

NOZZLE

Cross reference number

BOSCH

9 400 616 194

9400616194

ZEXEL

101701-9470

1017019470

NISSAN-DIESEL

16801Z6000

16801z6000

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8310

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2240

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED4 control unit part number

407915-0

590

RED4 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.5

3.47

3.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(10.2)

PWM

%

45.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

51.5

50.5

52.5

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Injection quantity adjustment_02

Rack position

(7.6)

PWM

%

30.7+-2.

8

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

13

12

14

Max. variation between cylinders

%

0

-8

8

Governor adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.3

Governor adjustment_03

Pump speed

r/min

1270

Advance angle

deg.

4

3.7

4.3

Remarks

Finish

Finish

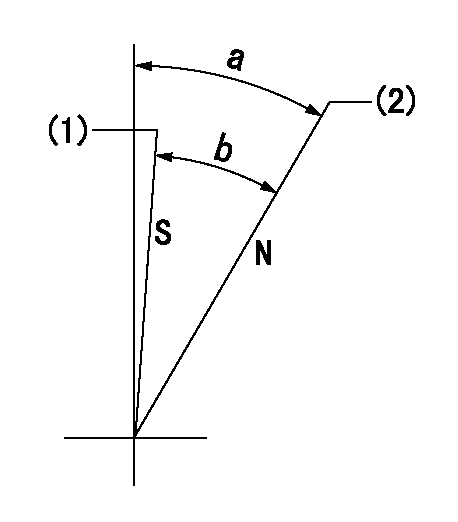

Test data Ex:

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=20mm

----------

a=38.5deg+-5deg b=37deg+-5deg

----------

aa=1mm bb=20mm

----------

a=38.5deg+-5deg b=37deg+-5deg

0000000901

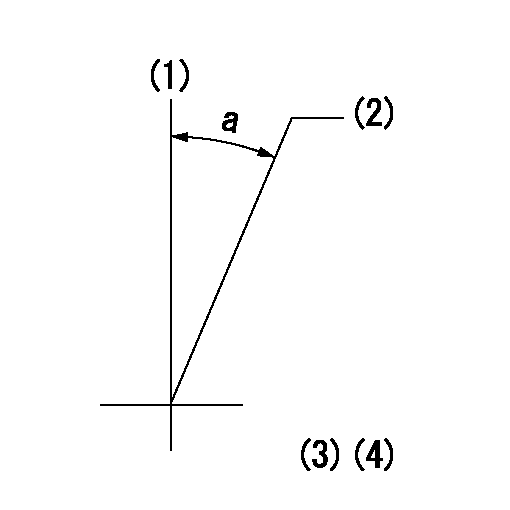

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(10deg)

----------

----------

a=(10deg)

Stop lever angle

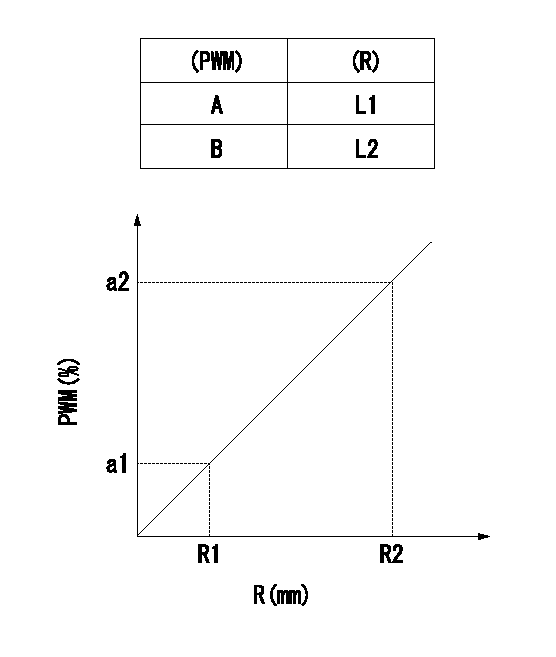

(PWM) Pulse width modulation (%)

(R) Rack position (mm)

Rack sensor output characteristics

1. Rack limit adjustment

(1)Measure the rack position R2 for PWM a2%.

(2)Confirm that it is within the range R2 = 15+-1 mm.

(3)Measure the rack position R1 at PWM a %.

(4)Confirm that it is within the range R2 - R1 = 10+-0.1 mm.

2. Check the limp home operation.

(1)Move the switch box's limp home switch to the limp home side.

(2)Confirm rack position L1 (mm ) and L2 (mm) for PWM in the above table.

3. Check the pull down operation.

(1)Confirm that the rack position is 19 mm at PWM B%.

(2)In the conditions described in the above table, move the switch box's pull down switch to the pull down side and confirm that the rack position momentarily becomes 1 mm or less.

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------