Information injection-pump assembly

BOSCH

9 400 615 970

9400615970

ZEXEL

101691-1750

1016911750

MITSUBISHI

3116142031

3116142031

Rating:

Service parts 101691-1750 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

31161-18000

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

101691-1750

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 615 970

9400615970

ZEXEL

101691-1750

1016911750

MITSUBISHI

3116142031

3116142031

Zexel num

Bosch num

Firm num

Name

101691-1750

9 400 615 970

3116142031 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6DC20 * K 14BE INJECTION PUMP ASSY PE6A PE

6DC20 * K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-3-4-

5-6

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-4 deg. 165 164.5 165.5

Cal 1-4 deg. 165 164.5 165.5

Difference between angles 4

Cal 1-5 deg. 240 239.5 240.5

Cal 1-5 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-6 deg. 285 284.5 285.5

Cal 1-6 deg. 285 284.5 285.5

Injection quantity adjustment

Adjusting point

B

Rack position

12.3

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

111

107.5

114.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

10.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

87

82.5

91.5

Max. variation between cylinders

%

0

-5

5

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

6.3+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

12

9.4

14.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

A

Rack position

-

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

112

108.5

115.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

14.5++

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

115

115

Fixing the lever

*

Remarks

Excess fuel for starting.

Excess fuel for starting.

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

2

1.4

2.6

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

4

3.4

4.6

Timer adjustment_04

Pump speed

r/min

1250

Advance angle

deg.

6.5

5.9

7.1

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

10

10

10

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

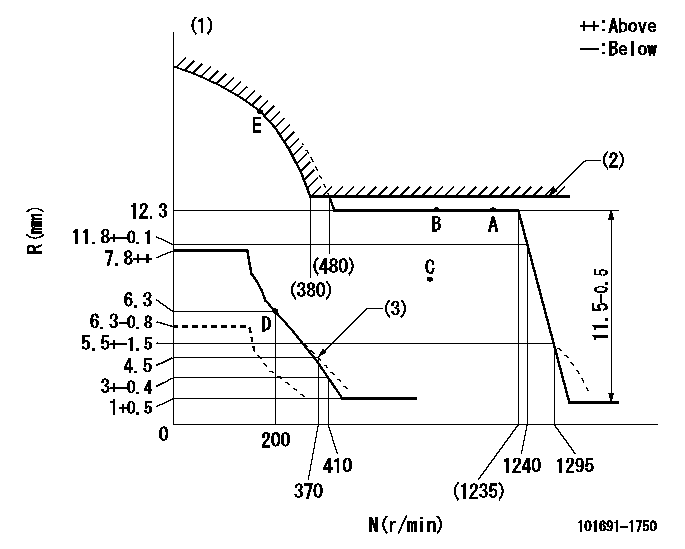

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Rack limit using excess fuel device for starting; RAL (at N = N1).

(3)Damper spring setting

----------

RAL=12.3+0.2mm N1=430r/min

----------

----------

RAL=12.3+0.2mm N1=430r/min

----------

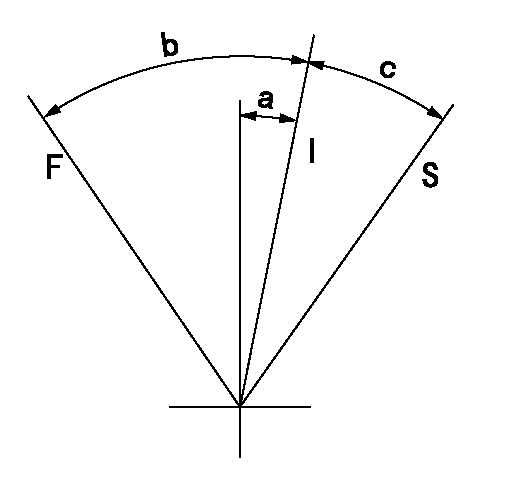

Speed control lever angle

F:Full speed

----------

----------

a=(12.5deg)+-5deg

----------

----------

a=(12.5deg)+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=11deg+-5deg b=41deg+-3deg c=10deg+-3deg

----------

----------

a=11deg+-5deg b=41deg+-3deg c=10deg+-3deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=6.3+0.2mm

----------

----------

N1=325r/min Ra=6.3+0.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(10deg)

----------

----------

a=(10deg)

Information:

Illustration 13 g02915447

Plugged DOC

The DOC utilizes a “pass-through” technology, which is different from the “wall flow” design of a DPF. When a light is shined through the DOC, a visible light should be able to pass through. Utilize a flashlight to check for a plugged DOC face. Aim the flashlight into the DOC inlet, visible light should be seen through the DOC. A plugged DOC can be caused by high oil consumption, not recommended fuel additives, or wrong engine oil types. Refer to the Operation and Maintenance Manual for recommended fluids to use. If light cannot be seen on the outlet of the DOC, then replace the DOC.CRS Bodies

Illustration 14 g06342815

Combustion Group

(1) Head Group - Combustion

(2) Gasket

(3) Tube

(4) Body Assembly - Exhaust CombustionCRS Combustion Body (4) contains the flame necessary for CRS Regeneration. There are two combustion stages that occur within the CRS Body: the primary and secondary combustion. The primary combustion of air and fuel occur within Tube (3) to create the CRS flame immediately following Head Group (1). The secondary combustion of the CRS flame and exhaust gas from the turbocharger occur within Body Assembly (4).The body assembly is the only salvageable part of the combustion group. The body assembly must be cleaned, inspected, and pressure tested prior to reuse.Cleaning

Start by isolating the CRS body from all other CRS exhaust components. Remove the head group, the mounting studs, the tube, and the two gaskets.The gasket area and the bellows joints are the two areas of the CRS body that must be cleaned thoroughly to make a proper seal.Cleaning the remainder of the CRS body is not required. If cleaning the CRS body is desired, then first perform the visual inspection, vacuum inspection, and welding procedures prior to washing the CRS body. This step is to ensure that the CRS body is salvageable, not cracked, and to keep water from getting trapped behind the heat shield.If washing is preferred, then use soap and water as a cleaning solution. Do not submerge the CRS body to prevent water from becoming trapped between the heat shield and the CRS body. A cylinder washing brush, a wire brush with handle, and a greenScotch Brite pads are all acceptable cleaning equipment. Removal of all diesel particulates is not required for inspection.

Do not use any combustible solvents to clean the CRS body.

Visual Inspection

A visual inspection of the CRS body must be completed, special equipment or crack detecting solution is not required. Visually inspect the exterior of the CRS body. Small cracks and/or punctures found on the stainless steel heat shield is normal and should be expected. Inspect the bellows sealing joints and the CRS head mating surface for visual damage.Light surface rust is typically not a problem unless rust is found on a bellows joint or the CRS gasket mating surface. Light rust in these two areas must be removed using a Scotch Brite pad.Serviceability

All bolts, studs, and clamps are not reusable and must be replaced with new components.Any thread damage in the mounting

Have questions with 101691-1750?

Group cross 101691-1750 ZEXEL

Mitsubishi

101691-1750

9 400 615 970

3116142031

INJECTION-PUMP ASSEMBLY

6DC20

6DC20