Rating:

Information injection-pump assembly

ZEXEL

101642-2180

1016422180

HINO

6057107510

6057107510

Service parts 101642-2180 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

6-051-17590-1

12.

Open Pre:MPa(Kqf/cm2)

11.8{120}

15.

NOZZLE SET

Include in #1:

101642-2180

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

101642-2180

1016422180

HINO

6057107510

6057107510

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105780-0020

Bosch type code

DN4SD24T

Nozzle holder

105031-2010

Bosch type code

KB56SD273

Opening pressure

MPa

11.8

Opening pressure

kgf/cm2

120

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

1.95

1.9

2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

47.5

46.5

48.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.2+-0.

5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

50.5

49.5

51.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

23.5

20.7

26.3

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

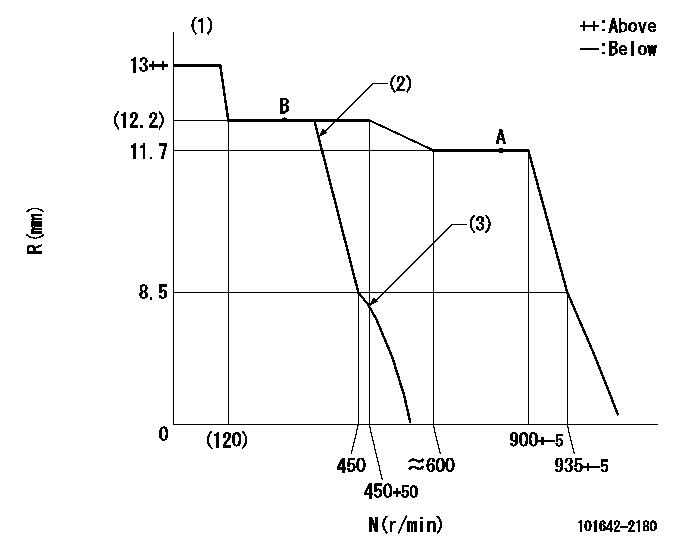

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Set minimum speed.

(3)Beginning of idle sub spring operation: L1

----------

K=15 L1=8.5-0.2mm

----------

----------

K=15 L1=8.5-0.2mm

----------

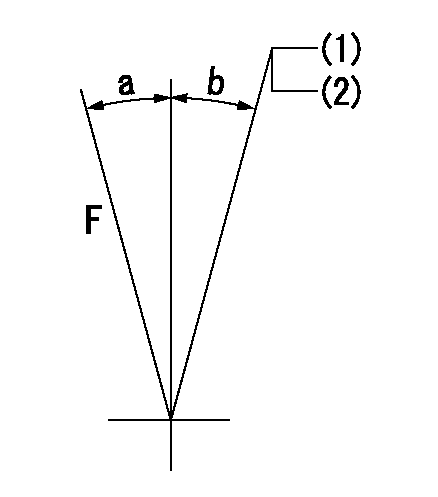

Speed control lever angle

F:Full speed

(1)Pump speed = aa

(2)Set minimum speed.

----------

aa=450r/min

----------

a=11.5deg+-5deg b=5.5deg+-5deg

----------

aa=450r/min

----------

a=11.5deg+-5deg b=5.5deg+-5deg

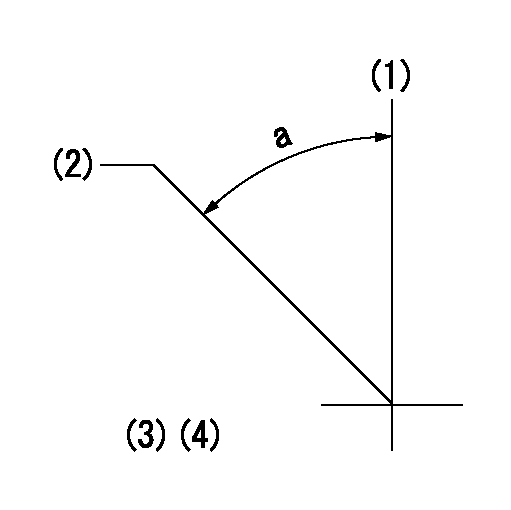

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)