Rating:

Information injection-pump assembly

ZEXEL

101607-6352

1016076352

Cross reference number

ZEXEL

101607-6352

1016076352

Zexel num

Bosch num

Firm num

Name

101607-6352

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

101.8

98.7

104.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

11.5

9.8

13.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

101.8

100.8

102.8

Basic

*

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

117.9

113.9

121.9

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

4)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

92.6

88.6

96.6

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_06

Adjusting point

E

Rack position

R1+0.7

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

113.5

109.5

117.5

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_07

Adjusting point

F

Rack position

(R2-0.75

)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

48.2

46.2

50.2

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

(R2-0.75

)

Boost pressure

kPa

3.3

2

4.6

Boost pressure

mmHg

25

15

35

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1-0.

4)

Boost pressure

kPa

22.7

22.7

22.7

Boost pressure

mmHg

170

170

170

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1340

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

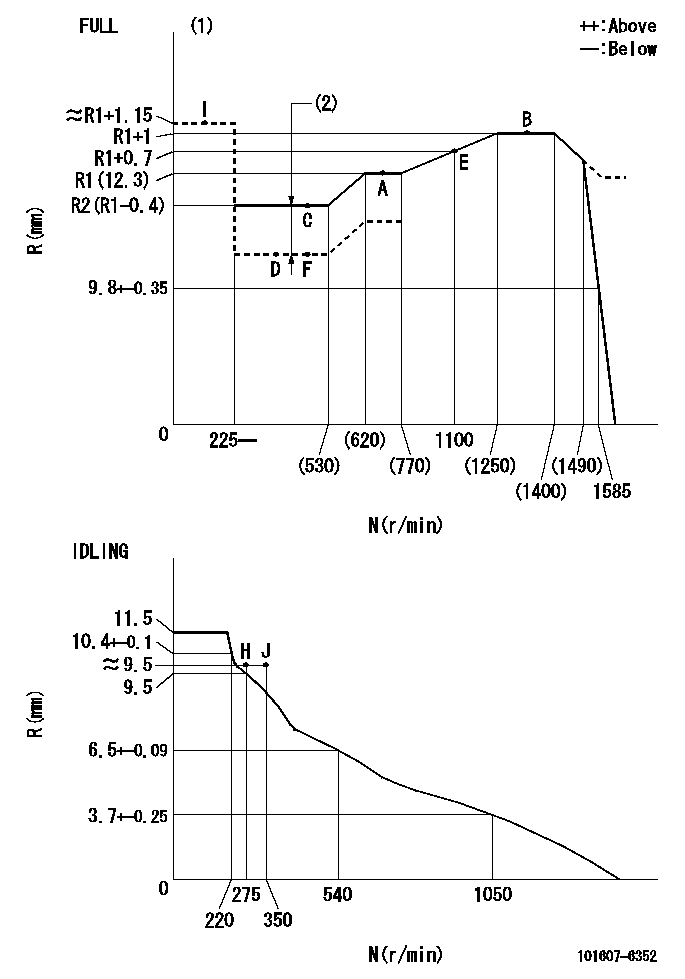

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Boost compensator stroke: BCL

----------

T1=H52 BCL=(0.75)+-0.1mm

----------

----------

T1=H52 BCL=(0.75)+-0.1mm

----------

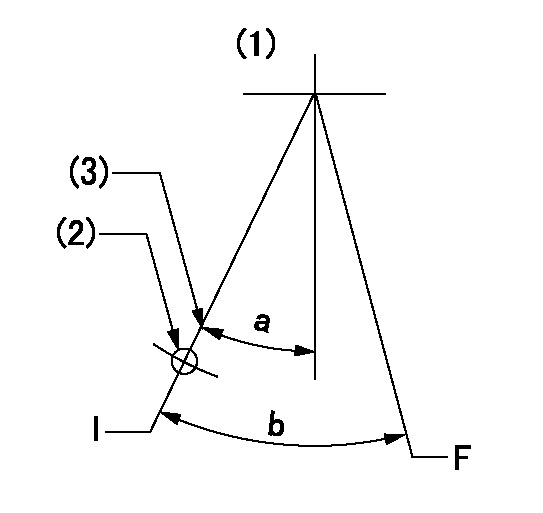

Speed control lever angle

F:Full speed

I:Idle

(1)Accelerator lever

(2)Use the hole at R = aa

(3)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=41deg+-5deg b=(42deg)+-3deg

----------

aa=35mm

----------

a=41deg+-5deg b=(42deg)+-3deg

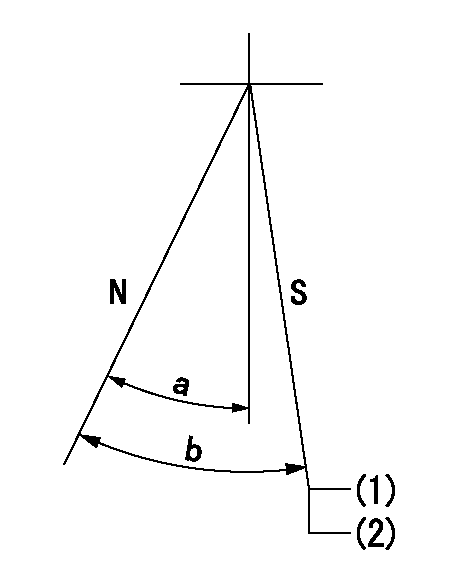

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

----------

aa=1350r/min bb=7-0.5mm cc=275r/min dd=(8)mm

----------

a=25deg+-5deg b=27deg+-5deg

----------

aa=1350r/min bb=7-0.5mm cc=275r/min dd=(8)mm

----------

a=25deg+-5deg b=27deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

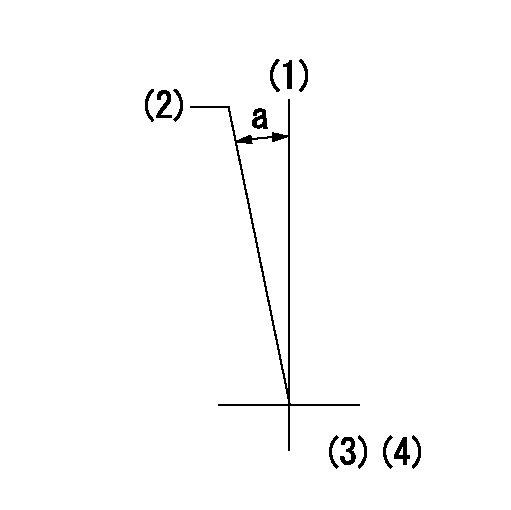

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(0deg)

----------

aa=11deg

----------

a=(0deg)

Have questions with 101607-6352?

Group cross 101607-6352 ZEXEL

Mitsubishi

Mitsubishi

101607-6352

INJECTION-PUMP ASSEMBLY