Rating:

Information injection-pump assembly

ZEXEL

101603-4573

1016034573

ISUZU

1156022493

1156022493

Service parts 101603-4573 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-213-1

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Cross reference number

ZEXEL

101603-4573

1016034573

ISUZU

1156022493

1156022493

Zexel num

Bosch num

Firm num

Name

101603-4573

1156022493 ISUZU

INJECTION-PUMP ASSEMBLY

6BG1-S * K

6BG1-S * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.1

75.5

78.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

77.1

76.1

78.1

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

88.7

84.7

92.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

93

93

101

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1275

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

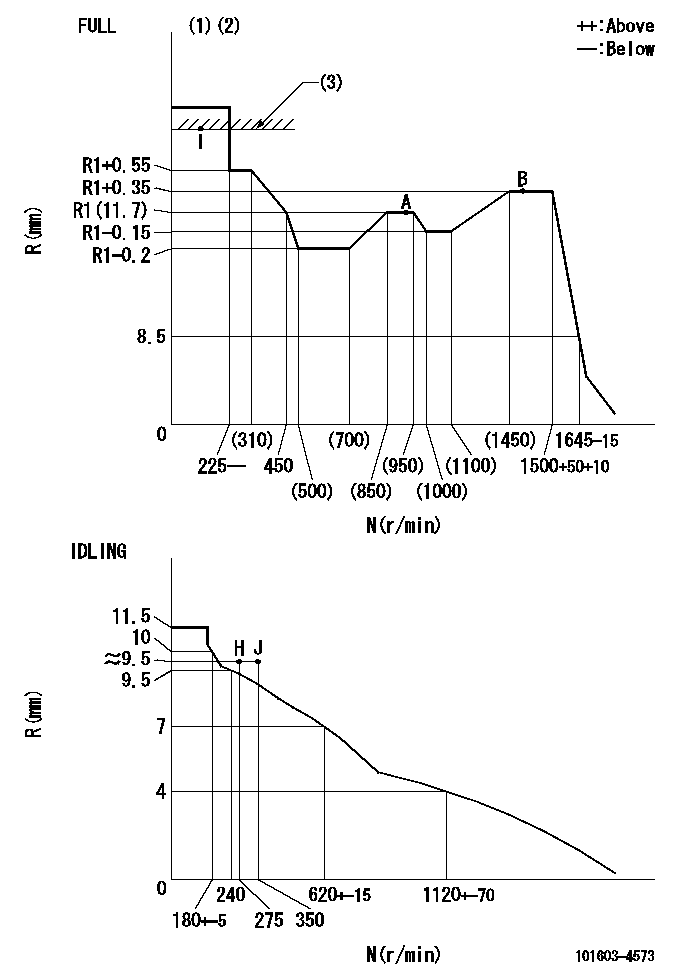

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Torque control stroke: L1

(3)RACK LIMIT

----------

T1=D07 L1=(1.5)mm

----------

----------

T1=D07 L1=(1.5)mm

----------

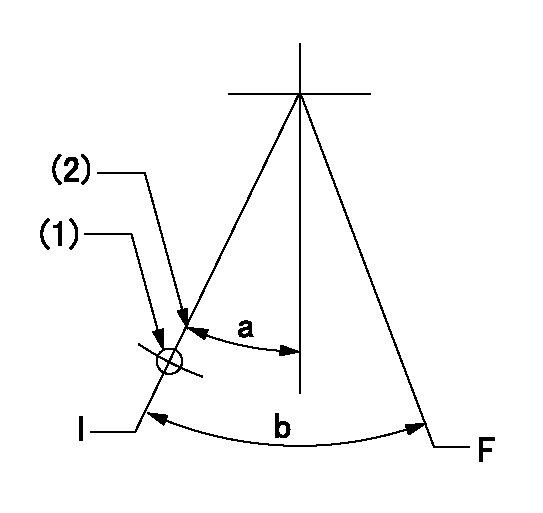

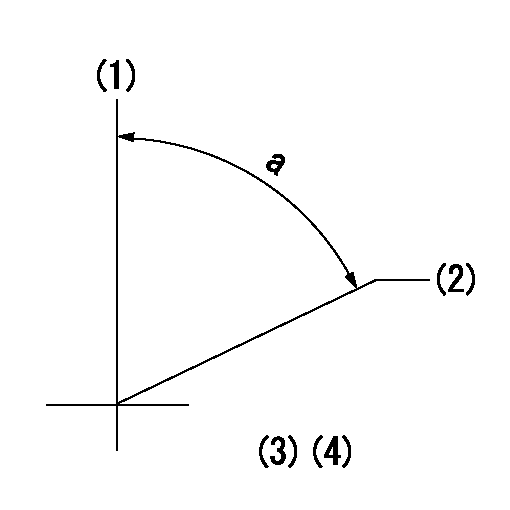

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=45mm

----------

a=21.5deg+-5deg b=(38deg)+-3deg

----------

aa=45mm

----------

a=21.5deg+-5deg b=(38deg)+-3deg

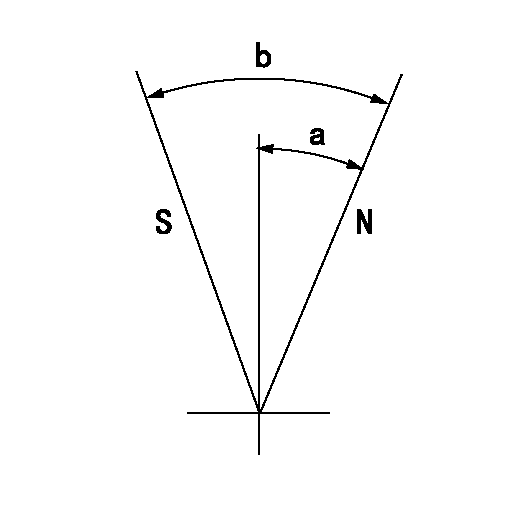

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

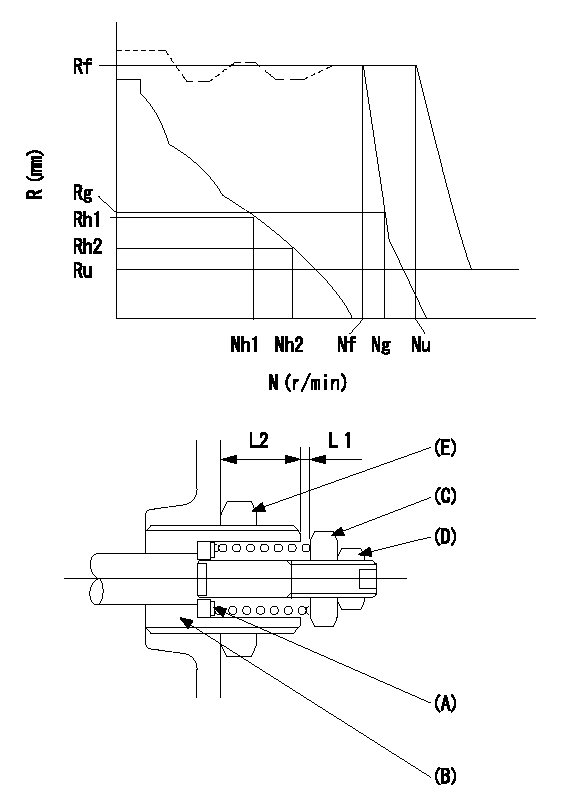

0000001501 VARIABLE TORQUE CONTROL

N:Pump speed (r/min)

R:Rack position (mm)

Adjusting shim A

Guide screw B

(c) Nut

(d) Nut

(e) nut

Torque control spring adjustment method for model responding to speed droop

[Advice]

Confirm that adjusting shim (A) thickness t = 1.3~1.5 mm is assembled before beginning adjustment.

(1)Temporary idle lever position setting

1. Refer to the RLD type governor service manual (Publication no. EE13E-11083).

(2)Idling spring adjustment

1. Refer to the RLD type governor service manual (Publication no. EE13E-11083).

(3)Governor spring setting adjustment

1. Temporarily fix so that the governor shaft's guide screw B protrudes L2 (18 mm) from the end of the governor.

2. Set the control lever where it contacts the idle stopper bolt.

3. Increase the speed to Nh2+100 r/min or more.

4. Adjust using the two nuts C and D so that L1 = 0.3+0.5 mm and fix temporarily.

5. Adjust the protrusion L2 of the guide screw (B) so that the rack position at Nh1 is Rh1 and at Nh2 is Rh2. Then fix using the nut (E).

6. Further increase the speed and readjust the two nuts (C) and (D) so that there is no change in L1 until Nf+50 r/min. Then fix temporarily.

[Advice]

When L1 becomes smaller while speed is increasing to Nf+50 r/min, decrease speed by Nh2+100 r/min.

Adjust so that L1 is even smaller, then again increase speed to Nf+50 r/min and confirm that L1 does not change.

(4)Full load position setting

1. Refer to the RLD type governor service manual (Publication no. EE13E-11083).

(5)Torque control spring adjustment

1. Set the control lever so that it contacts the full speed stopper bolt.

2. At the specified speed Nf, adjust using the full speed stopper bolt so that governing begins, then fix temporarily.

3. Increase the speed and adjust using the two nuts (C) and (D) so that the rack position Rg can be obtained at the specified speed Ng. Fix temporarily.

4. Decrease the speed and confirm the governing point (the beginning of governing point) at the specified speed Nf.

5. Set the speed at Nf-50 r/min.

6. Measure the torque control stroke (L1) and adjust to the specified stroke (L1) using the shim (A).

7. After completing shim adjustment, repeat the above adjustment using the two nuts.

8. After confirming the specifications Nf and Ng, fix the two nuts (C) and (D).

9. In this condition, increase the speed and confirm that R = 0 can be obtained.

(6)Full speed lever position setting

1. Set the control lever so that it contacts the full speed stopper bolt.

2. At the specified speed Nu, adjust using the full speed stopper bolt so that governing begins, then fix temporarily

3. Increase the speed and confirm that the specified rack position Ru can be obtained.

4. Adjust using the full speed stopper bolt so that governing begins at the specified speed Nf, then fix.

5. Confirm that the result is the same as that in '(5) Torque control spring adjustment.'

6. Confirm that the control lever operating angle is within the specifications.

(7)Rack limit adjustment

1. Refer to the RLD type governor service manual (Publication no. EE13E-11083).

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at the No. 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(60deg)

----------

aa=13deg

----------

a=(60deg)

Have questions with 101603-4573?

Group cross 101603-4573 ZEXEL

Isuzu

Isuzu

Isuzu

101603-4573

1156022493

INJECTION-PUMP ASSEMBLY

6BG1-S

6BG1-S