Rating:

Information injection-pump assembly

ZEXEL

101601-5170

1016015170

HINO

220000652B

220000652b

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$20.20

08 Jun 2021

US: # 1 Quality Parts

Lube Filter - Baldwin - PT396; Fleetguard - HF6090; Komatsu - 101-60-15170, 101-60-15171, 101-601-5171; Wix - 51534

Parts Express We have the best quality products in all brands, price and excellent after-sales service || Hydraulic and Oil Filter - None

Parts Express We have the best quality products in all brands, price and excellent after-sales service || Hydraulic and Oil Filter - None

$20.20

08 Jun 2021

US: # 1 Quality Parts

Lube Filter - Baldwin - PT396; Fleetguard - HF6090; Komatsu - 101-60-15170, 101-60-15171, 101-601-5171; Wix - 51534

Parts Express We have the best quality products in all brands, price and excellent after-sales service || Hydraulic and Oil Filter - None

Parts Express We have the best quality products in all brands, price and excellent after-sales service || Hydraulic and Oil Filter - None

$18.62

08 Jun 2021

1.0[0.45] Pounds

US: DB ELECTRICAL STARTE

Complete Tractor New HF3811 Lube Oil Filter Compatible with/Replacement for Komatsu -101-60-15170 101-601-5171 101-60-15171

Complete Tractor Specs: Lube Filter || Compatible with/Replacement for Baldwin: PT396 Fleetguard: HF6090 Komatsu: 101-60-15170, 101-60-15171, 101-601-5171 Wix: 51534 || Compatible With / Replacement For: Komatsu D20A-3 Crawler, D20P-3 Crawler, D20PL-3 Crawler, D20Q-3 Crawler, D20S-3 Crawler, D21A-3 Crawler, D21P-3 Crawler, D21PL-3 Crawler, D21Q-3 Crawler, D21S-3 Crawler, D30A-15 Crawler, D30P-15 Crawler, D30Q-15 Crawler, D30S-15 Crawler, D31A-15 Crawler, D31P-15 Crawler, D31Q-15 Crawler, D31S-15 Crawler, D40A-1 Crawler, D40P-1 Crawler, D40PL-1 Crawler, D40PLL-1 Crawler, D45A-1 Crawler, D45E-1 Crawler, D45P-1 Crawler, D45S-1 Crawler, D50A-16 Crawler || 1-year warranty covers you throughout planting and harvesting seasons || 100% new Lube Filter meets OEM quality for tractors and farm equipment

Complete Tractor Specs: Lube Filter || Compatible with/Replacement for Baldwin: PT396 Fleetguard: HF6090 Komatsu: 101-60-15170, 101-60-15171, 101-601-5171 Wix: 51534 || Compatible With / Replacement For: Komatsu D20A-3 Crawler, D20P-3 Crawler, D20PL-3 Crawler, D20Q-3 Crawler, D20S-3 Crawler, D21A-3 Crawler, D21P-3 Crawler, D21PL-3 Crawler, D21Q-3 Crawler, D21S-3 Crawler, D30A-15 Crawler, D30P-15 Crawler, D30Q-15 Crawler, D30S-15 Crawler, D31A-15 Crawler, D31P-15 Crawler, D31Q-15 Crawler, D31S-15 Crawler, D40A-1 Crawler, D40P-1 Crawler, D40PL-1 Crawler, D40PLL-1 Crawler, D45A-1 Crawler, D45E-1 Crawler, D45P-1 Crawler, D45S-1 Crawler, D50A-16 Crawler || 1-year warranty covers you throughout planting and harvesting seasons || 100% new Lube Filter meets OEM quality for tractors and farm equipment

Cross reference number

ZEXEL

101601-5170

1016015170

HINO

220000652B

220000652b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.1

3.07

3.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

8.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

64.6

63.6

65.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.2+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

7.5

6.5

8.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.9)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

64.6

63.6

65.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105.5

105.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

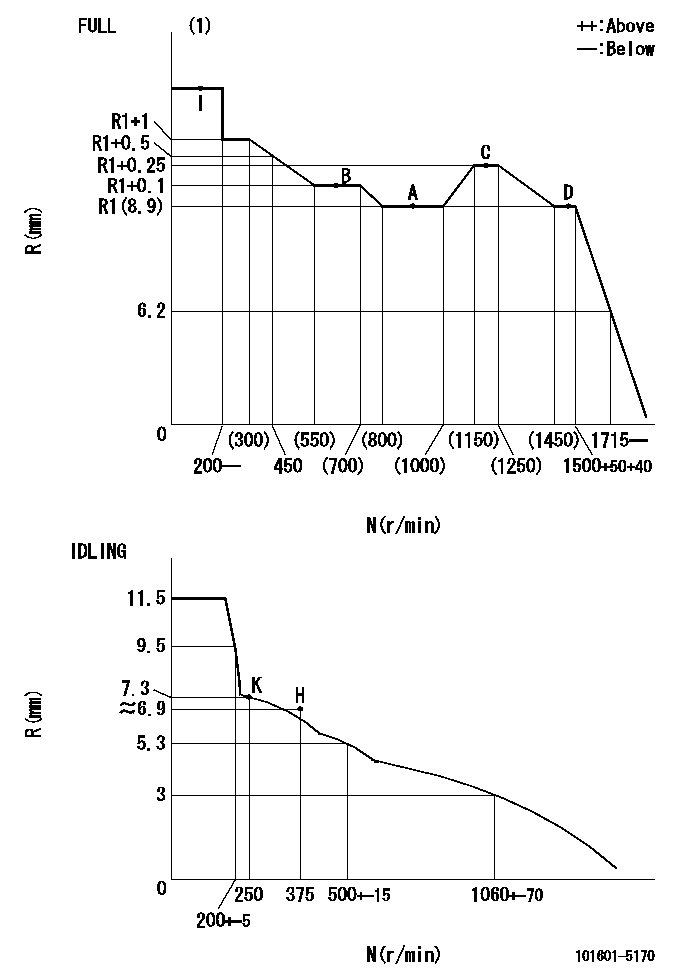

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

----------

T1=B70

----------

----------

T1=B70

----------

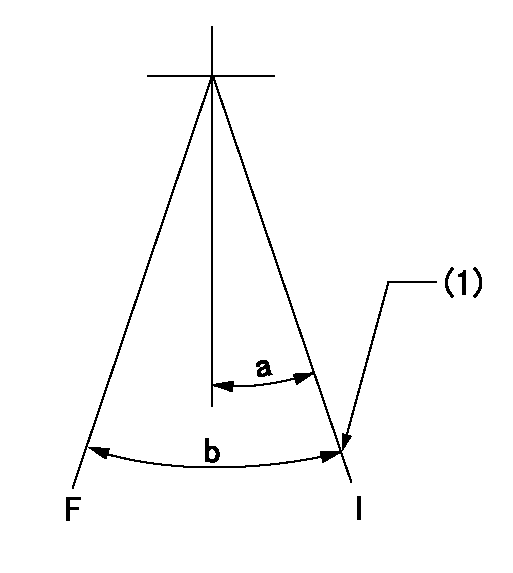

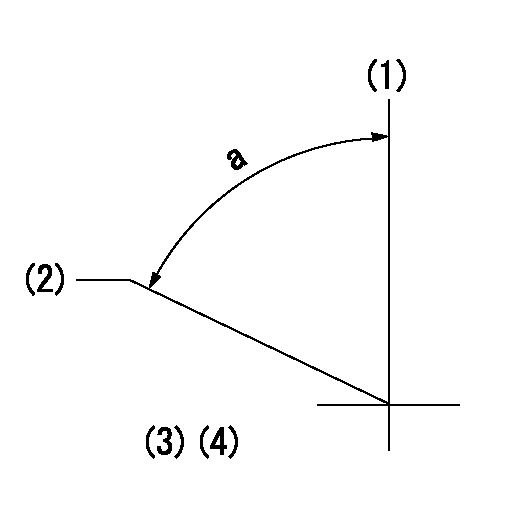

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'K'

----------

----------

a=30deg+-5deg b=41deg+-3deg

----------

----------

a=30deg+-5deg b=41deg+-3deg

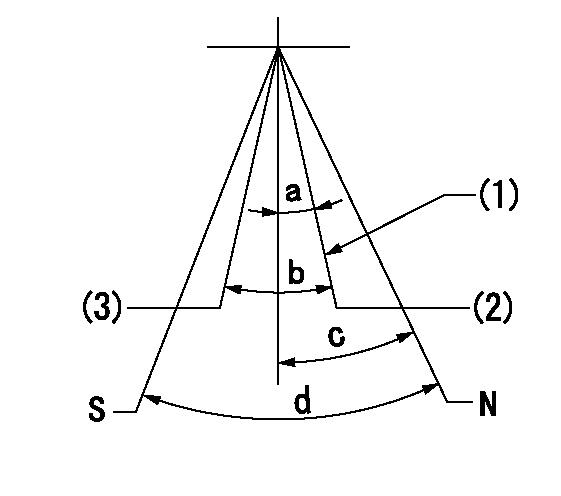

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the normal set bolt.

(2)Engine normal

(3)Engine stop

----------

----------

a=(0deg)+-5deg b=(13deg) c=16deg+-5deg d=40deg+-5deg

----------

----------

a=(0deg)+-5deg b=(13deg) c=16deg+-5deg d=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(55deg)

----------

----------

a=(55deg)