Rating:

Information injection-pump assembly

BOSCH

9 400 614 210

9400614210

ZEXEL

101481-9294

1014819294

NISSAN-DIESEL

1670002D01

1670002d01

Service parts 101481-9294 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-01D02

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 614 210

9400614210

ZEXEL

101481-9294

1014819294

NISSAN-DIESEL

1670002D01

1670002d01

Zexel num

Bosch num

Firm num

Name

101481-9294

9 400 614 210

1670002D01 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD35T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

FD35T K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.6

2.55

2.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.4

74.8

78

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8.5+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

10.5

8.5

12.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76.4

75.4

77.4

Basic

*

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.2

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

87.1

83.1

91.1

Fixing the lever

*

Boost pressure

kPa

80

80

Boost pressure

mmHg

600

600

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

84

84

94

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

1000

1000

1000

Rack position

(R1-1.45

)

Boost pressure

kPa

26.7

24

29.4

Boost pressure

mmHg

200

180

220

Boost compensator adjustment_02

Pump speed

r/min

1000

1000

1000

Rack position

R1(11.1)

Boost pressure

kPa

66.7

60

73.4

Boost pressure

mmHg

500

450

550

Timer adjustment

Pump speed

r/min

1300

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1600

Advance angle

deg.

1.8

1.3

2.3

Timer adjustment_03

Pump speed

r/min

1800

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

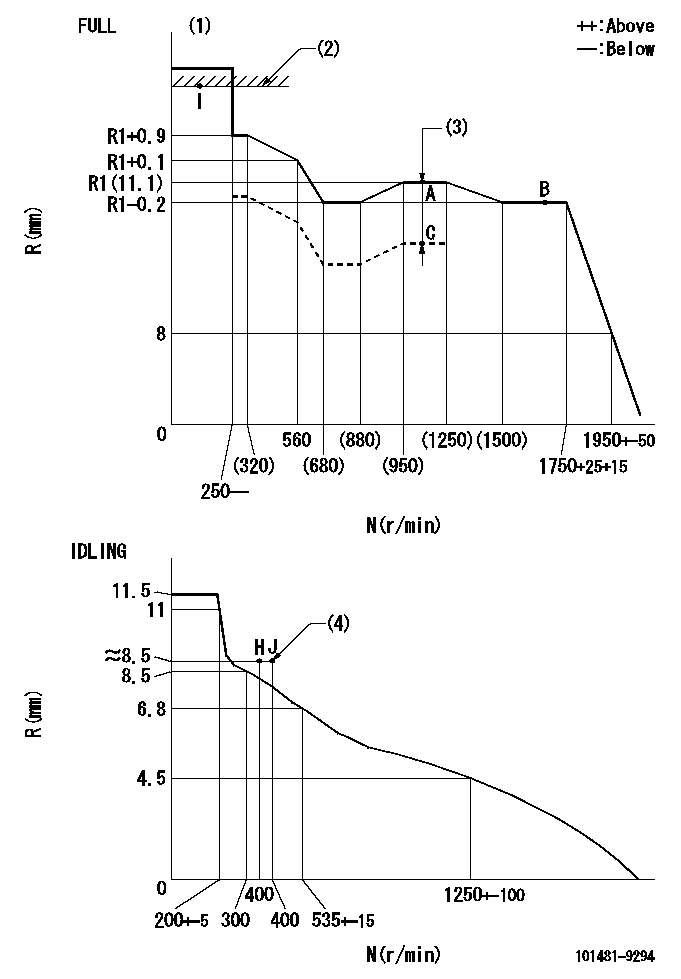

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

(4)Speed at operating limit of increased fuel quantity for starting: NS

----------

T1=D32 BCL=(1.45)+-0.1mm NS=400r/min

----------

----------

T1=D32 BCL=(1.45)+-0.1mm NS=400r/min

----------

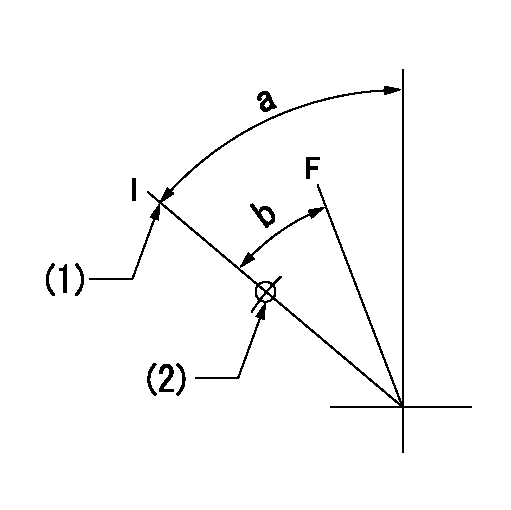

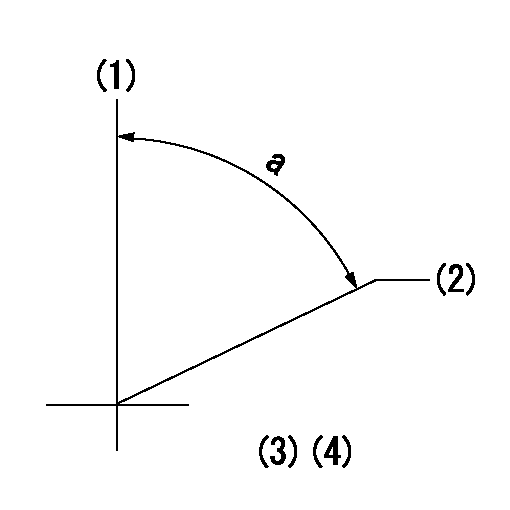

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

(2)Use the hole at R = aa

----------

aa=32mm

----------

a=56deg+-5deg b=(30deg)+-3deg

----------

aa=32mm

----------

a=56deg+-5deg b=(30deg)+-3deg

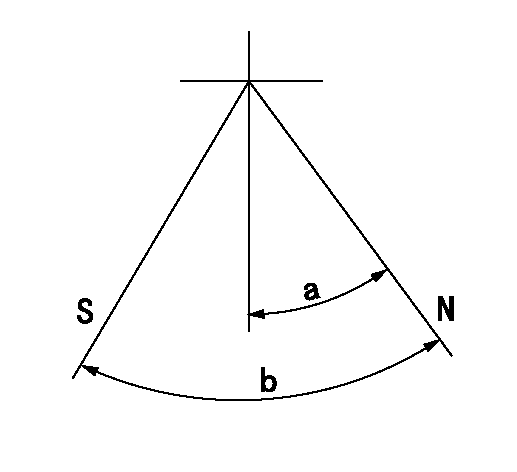

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=25deg+-5deg b=40deg+-5deg

----------

----------

a=25deg+-5deg b=40deg+-5deg

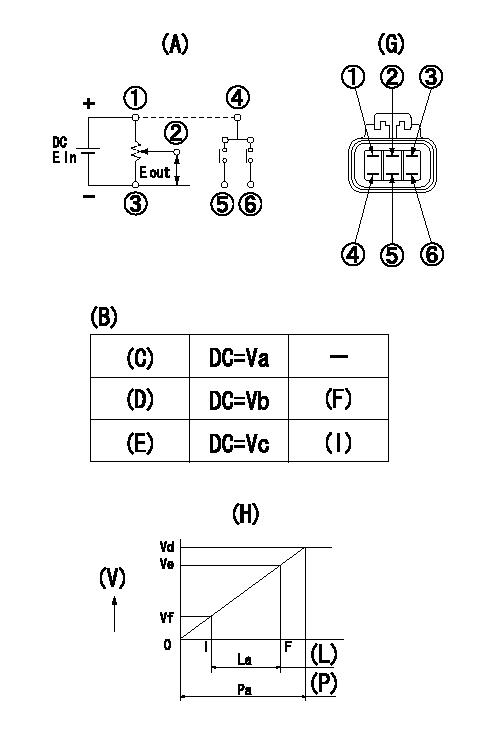

0000001501 POTENTIO METER

(A) Measuring circuit

(B) Specified voltage

(C) Supply voltage (E in)

(D) Output voltage (E out)

(E) Output voltage (E out)

(F) Speed lever: full position

(G) Potentiometer harness terminal shape

(H) Specified output voltage value

(I) Speed lever: Idle position

(L) Lever position

(P) Potentiometer electrical angle

(V) Output voltage

1. Potentiometer adjustment procedure

(1)Position the speed lever in the full speed position.

(2)Loosen the potentiometer body bolts and move the potentiometer left and right until the full output voltage is Ve from the above measuring circuit. Then, tighten the bolts.

(3)After setting Full, operate the speed lever and confirm that the lever does not stick.

(4)Hold the speed lever against the idle stopper bolt and confirm that idle output voltage is Vf.

(5)After confirming performance several times, complete adjustment.

----------

Va=5+-0.02V Vb=3.35+-0.2V Vc=0.555+-0.305V Vd=5V Ve=3.35+-0.2V Vf=0.555+-0.305V La=(30deg) Pa=53deg42min+-3deg

----------

----------

Va=5+-0.02V Vb=3.35+-0.2V Vc=0.555+-0.305V Vd=5V Ve=3.35+-0.2V Vf=0.555+-0.305V La=(30deg) Pa=53deg42min+-3deg

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard threaded hole at No 1 cylinder's beginning of injection (position of gear's 'M' mark)

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(60deg)

----------

aa=14deg

----------

a=(60deg)

Have questions with 101481-9294?

Group cross 101481-9294 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

101481-9294

9 400 614 210

1670002D01

INJECTION-PUMP ASSEMBLY

FD35T

FD35T